Maximize Uptime with Smart Breakdown Maintenance Solutions

Empower your organization with MaintWiz CMMS - the ultimate tool for transforming reactive maintenance into proactive reliability. Reduce downtime, cut costs, and boost operational efficiency today.

Breakdown Maintenance

Dive into Detailed Product Information and address your common queries.

Speak to a Specialist

Get personalised advice from our experts

Optimize Breakdown Maintenance for Maximum Uptime

Revolutionize your maintenance strategy and keep your assets running at peak performance.

Slash Equipment Downtime with Instant Failure Alerts

MaintWiz’s real-time notification system ensures immediate response to breakdowns. Our smart alerts prioritize critical issues, allowing your team to address problems swiftly and minimize production losses.

Streamline Machine Breakdown Management for Efficiency

Gain complete visibility into your maintenance operations with our intuitive dashboard. Track repair progress, allocate resources effectively, and make data-driven decisions to optimize your breakdown maintenance processes.

Enhance Equipment Reliability Through Data-Driven Insights

Leverage MaintWiz’s powerful analytics to identify recurring issues and implement targeted improvements. Our system helps you transition from reactive repairs to proactive maintenance, significantly boosting asset reliability.

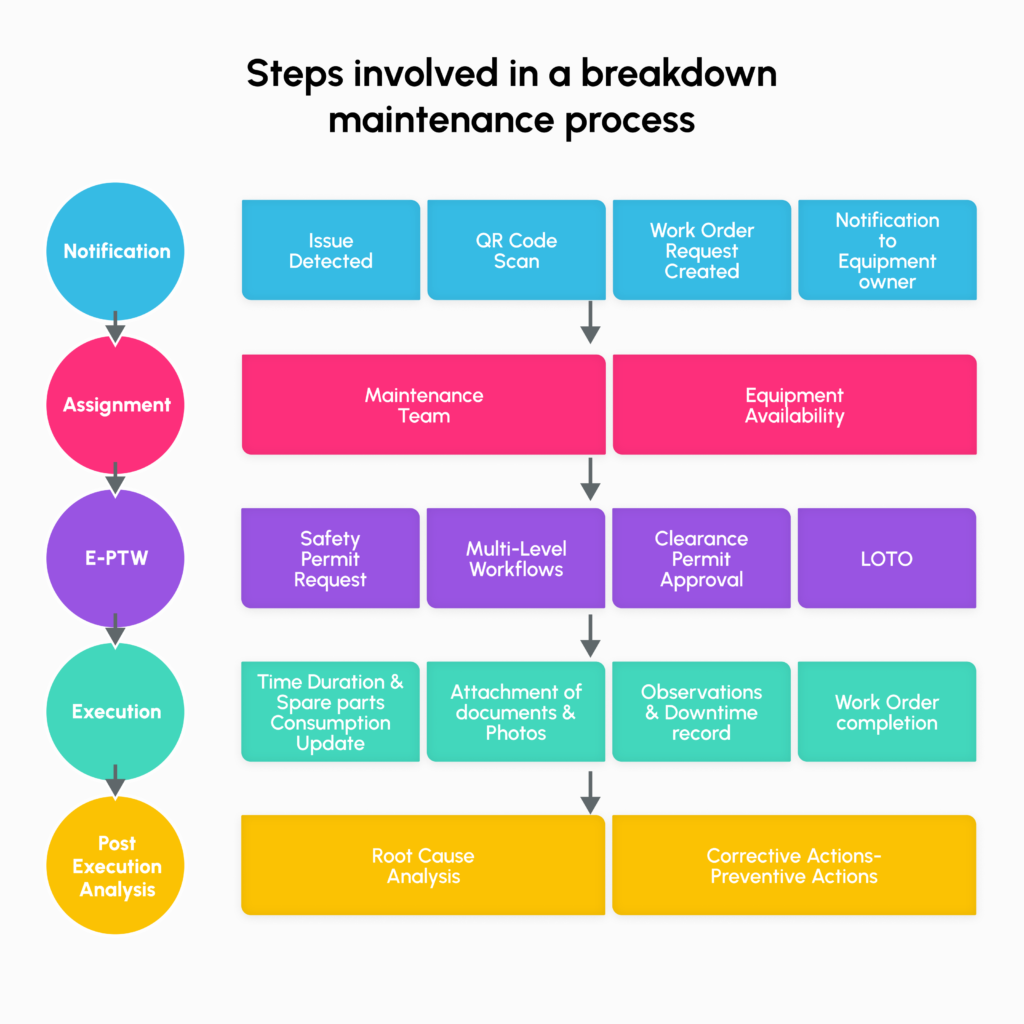

Supercharge Reactive Maintenance with Intelligent Workflows

MaintWiz’s AI-powered workflows automate your response to breakdowns. From work order generation to technician assignment, our system streamlines every step, ensuring rapid resolution of maintenance issues.

Predict and Prevent Failures with Advanced Asset Monitoring

Stay ahead of equipment breakdowns with MaintWiz’s continuous performance monitoring. Our system analyzes operational data in real-time, alerting you to potential issues before they escalate into costly failures.

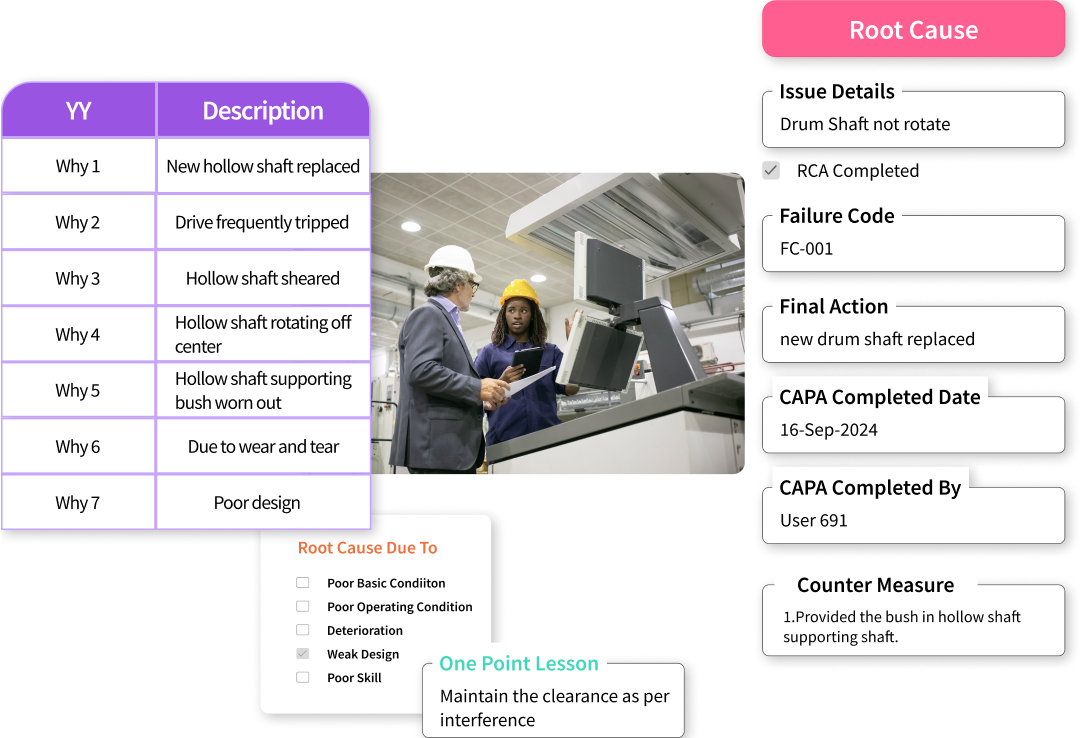

Uncover Root Causes to Bolster Long-Term Reliability

Dive deep into breakdown patterns with MaintWiz’s comprehensive root cause analysis tools. Identify systemic issues, implement lasting solutions, and dramatically improve your equipment’s long-term reliability and performance.

Top Companies in India & Abroad Trust MaintWiz CMMS

Data-Driven Breakdown Maintenance: Track, Report, Optimize

Harness the power of data to transform your maintenance strategy and drive operational excellence.

Unlock Insights with Comprehensive Breakdown Analytics

MaintWiz CMMS provides in-depth reports on asset performance, maintenance history, and repair costs. Identify your most problematic assets and make informed decisions to optimize your maintenance budget and resources.

Slash Repair Costs and Optimize Labor Utilization

Track every aspect of your repair expenses with MaintWiz’s detailed cost analysis tools. Reduce overtime labor costs, optimize spare parts usage, and improve overall maintenance efficiency to boost your bottom line.

Tailor Maintenance Strategies with Custom Reporting

Generate bespoke reports on breakdown trends, repair efficiency, and cost analysis. MaintWiz’s flexible reporting tools allow you to focus on the metrics that matter most to your organization’s unique needs.

Elevate Decision-Making with Advanced Failure Analysis

MaintWiz’s sophisticated failure analysis tools provide deep insights into equipment issues. Understand the root causes of breakdowns, prioritize maintenance tasks, and make data-backed decisions to improve asset reliability.

Forecast Future Failures with Historical Data Insights

Leverage MaintWiz’s powerful analytics to identify patterns in your breakdown data. Our system helps you anticipate potential issues across assets and locations, enabling proactive maintenance planning.

Prevent Breakdowns with Intelligent Condition Monitoring

MaintWiz integrates with IoT sensors to provide real-time condition monitoring. Detect early signs of equipment failure, schedule preventive maintenance, and avoid costly unplanned downtime before it occurs.

Our Benefits

Accelerate Reactive Maintenance Response with Automation

Minimize downtime and maximize efficiency with MaintWiz's cutting-edge automation features.

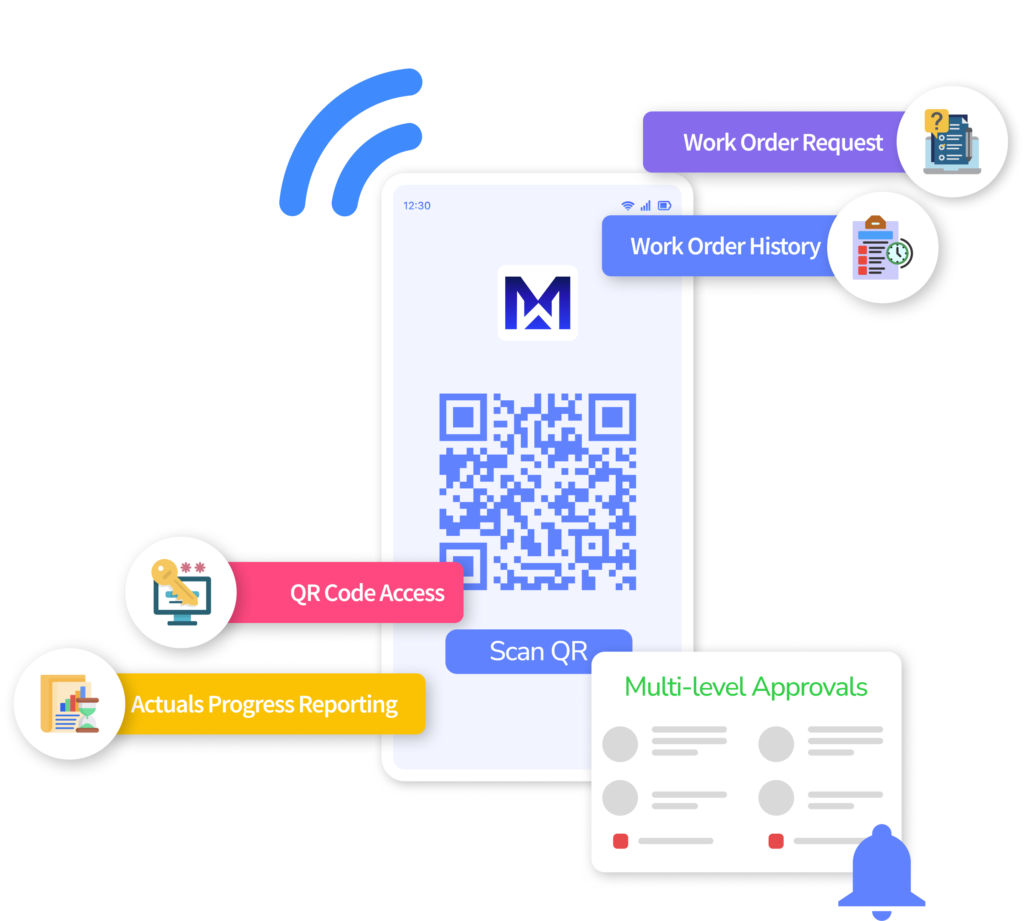

Access Critical Failure Data Anytime, Anywhere

MaintWiz’s mobile-friendly platform ensures your team has instant access to equipment failure information from any device. Make informed decisions on-the-go and respond to breakdowns with unprecedented speed.

Empower Field Technicians with Mobile Accessibility

Equip your maintenance team with MaintWiz’s powerful mobile app. Access work orders, equipment histories, and repair procedures in the field, dramatically improving response times and first-time fix rates.

Boost Team Performance with Real-Time Efficiency Metrics

Monitor your maintenance team’s performance with MaintWiz’s comprehensive tracking tools. Analyze response times, repair durations, and work order completion rates to continually improve your maintenance operations.

Minimize MTTR with Intelligent Workflow Optimization

MaintWiz’s smart workflows streamline every aspect of your reactive maintenance process. From rapid work order creation to efficient technician dispatching, our system helps you significantly reduce mean time to repair (MTTR).

Seamlessly Integrate Inventory Management with Repairs

MaintWiz’s integrated inventory system ensures your team always has the right parts for the job. Automatically track spare part usage, trigger reorders, and eliminate delays caused by parts shortages.

Stay Informed with Real-Time Repair Status Updates

Keep all stakeholders in the loop with MaintWiz’s real-time status updates. From work order initiation to job completion, our system provides instant visibility into the progress of every repair task

Voices of Our Valued Clients

Transform Breakdown Maintenance with MaintWiz CMMS

Elevate your maintenance strategy to new heights of efficiency and reliability.

Harness AI and IoT for Unparalleled Failure Prevention

MaintWiz leverages cutting-edge AI and IoT technologies to predict equipment failures before they occur. Our advanced analytics help you transition from reactive to proactive maintenance, dramatically reducing unplanned downtime.

Implement Precision Maintenance Scheduling

Say goodbye to unexpected breakdowns. MaintWiz’s intelligent scheduling system helps you plan maintenance activities at optimal times, balancing asset health with production demands to minimize disruptions.

Extend Asset Lifespan with Proactive Care

MaintWiz’s comprehensive asset lifecycle management tools help you optimize maintenance strategies for each piece of equipment. Reduce breakdown frequency, extend asset lifespan, and maximize your return on investment.

Gain Deep Insights into Equipment Health

MaintWiz provides a 360-degree view of your assets’ health and performance. Our powerful analytics tools help you identify trends, predict future maintenance needs, and make data-driven decisions to improve overall reliability.

Prevent Costly Failures with Intelligent CMMS Alerts

MaintWiz’s smart alert system keeps you one step ahead of potential breakdowns. Receive timely notifications about impending issues, allowing you to address problems proactively and avoid expensive emergency repairs.

Ensure Compliance and Maintain Best Practices

MaintWiz helps you stay on top of industry regulations and maintenance best practices. Our system guides your team through standardized procedures, ensuring consistent quality in all maintenance activities and reducing compliance risks.

Achieve Maintenance Excellence with our Comprehensive Solutions

Streamline Maintenance Operations. Simplify breakdown, preventive or predictive or turn-around maintenance. Leverage MaintWiz CMMS to quickly detect, respond, and resolve equipment failures. Optimize maintenance workflows and ensure uninterrupted productivity with our real-time solutions. Enhance asset longevity and operational stability with our integrated platform.

Preventive Maintenance

Enhance equipment reliability with proactive maintenance strategies that prevent failures.

Digital Logbook

Transition to a digital logbook for seamless recording and access to maintenance data.

OEE (Overall Equipment Effectiveness)

Optimize equipment performance with comprehensive OEE metrics and analytics.

Total Productive Maintenance (TPM)

Drive operational excellence with a holistic approach to total productive maintenance.

Condition Monitoring

Monitor equipment condition in real-time to detect issues before they lead to failures

Work Order Management

Improve operational efficiency with our intuitive work order tracking and management system.

Safety Permit Management

Ensure safety compliance with robust permit management and tracking systems.

Predictive Maintenance

Utilize predictive maintenance techniques to foresee and address potential equipment failures.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.

With MaintWiz, we can now resolve breakdowns faster, cutting unplanned downtime by 40%.