Boost Operational Efficiency with Advanced OEE Solutions

Discrete, Batch or Process Industry: Enhance Manufacturing Efficiency with MaintWiz OEE. Gain real-time insights, reduce downtime, and maximize output for sustained operational excellence. Leverage AI-driven analytics for smarter decision-making and predictive maintenance.

Maximize Equipment Availability with Intelligent Tracking

Harness the power of AI-enhanced availability tracking to minimize downtime and optimize production schedules. Our intelligent system adapts to your unique manufacturing environment, ensuring precise OEE calculations.

Flexible Shift Configurations for Optimal Production Scheduling

Adapt to varying production schedules with ease by configuring shifts flexibly. Availability calculations follow shifts schedule to ensure accurate OEE.

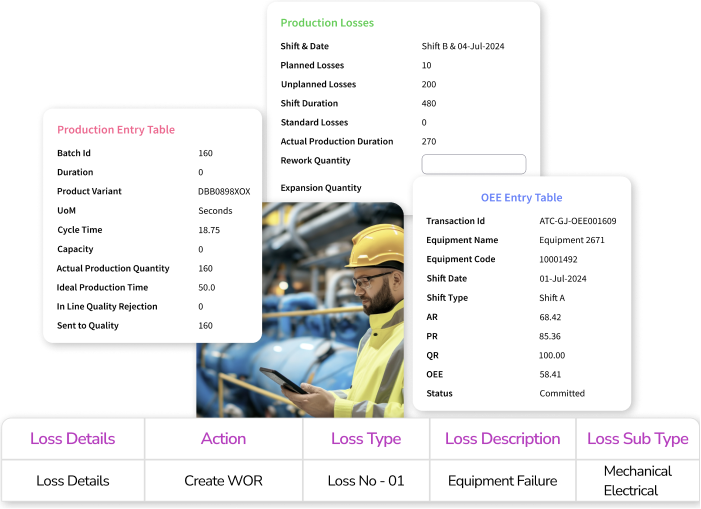

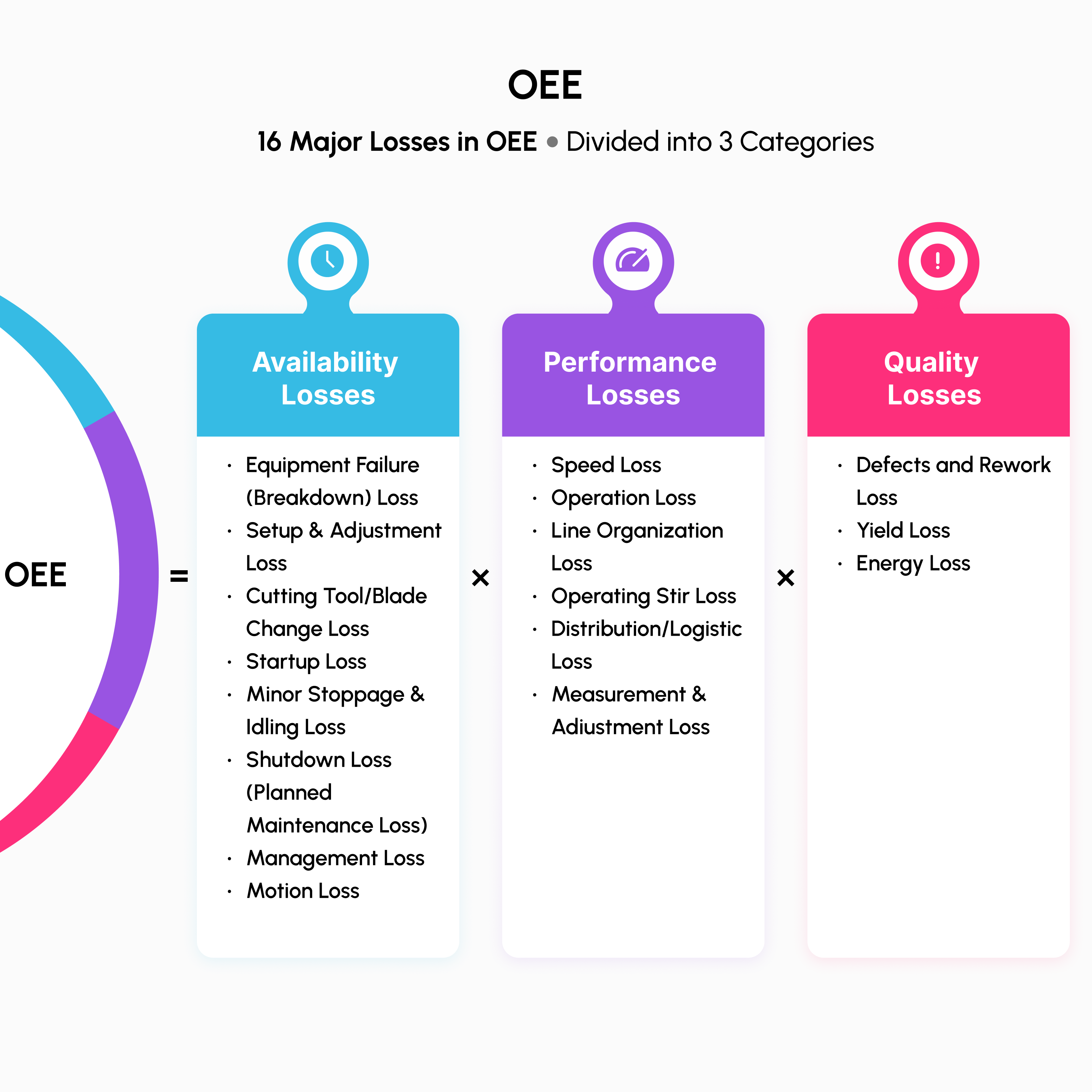

Comprehensive Loss Master for Effective Downtime Reduction

Centralize and manage all equipment loss data. Follow 5 or 16 big losses or your own classification. Losses are captured effectively to implement downtime reduction.

Manual and Automated Loss Tracking for Seamless Data Capture

Enter downtime via manual work orders or integrate and capture automated data. Effective loss data entry, shiftwise, at equipment level or line level.

AI-Powered Automatic Downtime Categorization for Enhanced Analysis

Streamline analysis and improvement efforts with AI-driven automatic categorization of downtime events, facilitating more efficient root cause analysis and implementation of corrective and preventive actions.

Advanced IoT Integration for Predictive Maintenance

Connect your equipment to the Industrial Internet of Things (IIoT). Enhanced real-time monitoring and AI-driven predictive maintenance helps in maximizing Availability Rate and Overall Equipment Effectiveness.

AI-Driven Equipment Health Monitoring for Proactive Maintenance

Leverage AI algorithms to continuously monitor equipment health, predicting potential failures before they occur. Enables timely interventions, reduces unexpected breakdowns, and significantly improves availability rate.

Elevate Quality Standards with Advanced Analytics

Utilize AI-enhanced quality control measures to minimize defects, optimize yield, and maintain exceptional product standards throughout your manufacturing process.

AI-assisted Defect Trend Analysis for Proactive Quality Management

Analyze defect trends over time using AI algorithms to identify root causes, reduce quality issues, and maintain high standards in your production processes.

Real-Time Quality Feedback with Machine Learning Integration

Receive immediate feedback on quality metrics powered by machine learning, allowing for quick adjustments and maintaining consistency in product output

First-Pass Yield Monitoring for Reduced Waste and Rework

Track first-pass yield to ensure that products meet quality standards on the first attempt, reducing rework and material waste.

AI-Assisted Root Cause Analysis (RCA) for Defect Reduction

Perform root cause analysis on defects using AI-driven insights, enabling you to implement effective corrective actions and preventive measures. Achieve continuous improvement.

Intelligent Yield Optimization for Maximum Output

Continuously monitor and improve yield rates using AI-powered optimization techniques to maximize output, reduce waste, and enhance overall production efficiency.

Customer Feedback Integration for Enhanced Product Satisfaction

Capture and analyze customer feedback into your quality control processes. Elevate service levels and improve product satisfaction.

Speak to a Specialist

Get personalised advice from our experts

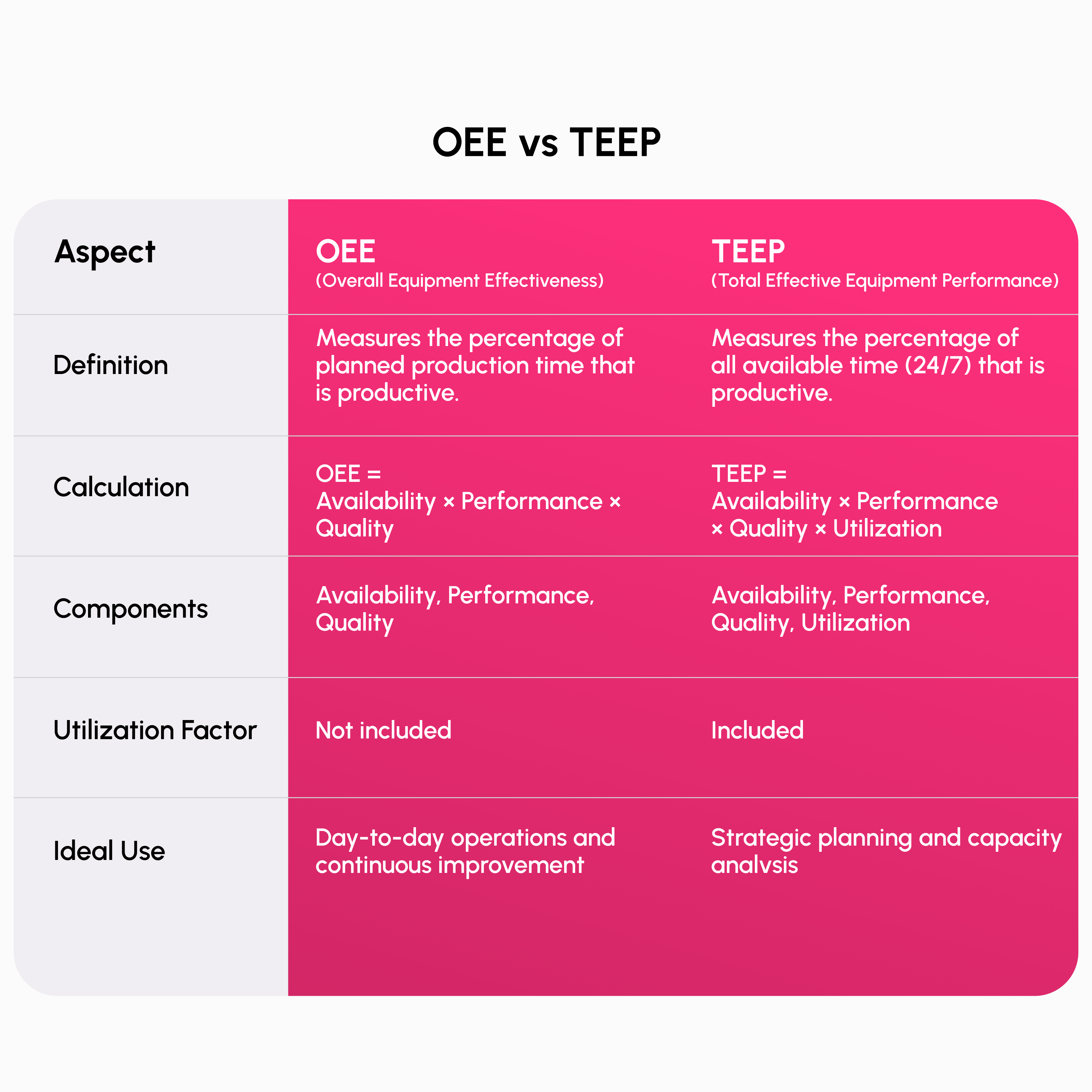

Comprehensive Metrics and Dashboards for Informed Decision-Making

Harness the power of AI-driven analytics and visualization tools to gain deep insights into your OEE performance, enabling data-driven decisions and continuous improvement.

AI-Powered Customizable OEE Dashboards for Tailored Insights

Create tailored OEE dashboards at machine, line, or plant level, leveraging AI to visualize key performance indicators and track progress by shift, day or month.

Interactive OEE Reports with AI-Enhanced Drill-Down Capabilities

Generate interactive reports with AI-powered drill-down capabilities, offering deeper insights into your operations and uncovering hidden patterns.

Predictive Historical Performance Analysis for Future Planning

Analyze historical OEE data using AI-driven predictive analytics to identify AR, PR, QR trends, benchmark performance, and make informed decisions for continuous improvement.

AI-Driven Loss Stratification for Targeted Improvement Strategies

Classify and analyze availability, performance, and cost losses using AI algorithms to understand their impact and implement targeted improvement strategies for Overall Equipment Effectiveness.

Mobile-Accessible Dashboards with Real-Time AI Insights

Access OEE dashboards on the go with mobile-friendly interfaces, featuring AI-powered real-time insights, ensuring you stay informed and in control, no matter where you are.

AI-Powered Bottleneck Identification for Optimal Production Flow

Identify and address bottlenecks in your production process quickly, using real-time data and advanced AI analytics to maintain optimal flow and maximize efficiency.

Achieve Operational Excellence Across Industries

Leverage AI-driven solutions tailored for discrete, batch, and process industries to streamline operations, enhance productivity, and drive continuous improvement across your entire manufacturing ecosystem.

Versatile AI Solutions for Discrete, Batch, and Process Industries

Adaptable to various industry needs, our AI-enhanced OEE software supports discrete, batch, and process manufacturing, offering versatile solutions for every sector.

AI-Driven Seamless Data Integration for Comprehensive Operations View

Integrate OEE data with other business systems effortlessly using AI-powered connectors, providing a comprehensive view of your operations and enabling smarter decisions.

Advanced AI Bottleneck Detection Tools for Proactive Operations Management

Identify production bottlenecks early using our advanced AI-powered tools, allowing you to take proactive measures and maintain smooth operations.

AI-Enhanced Real-Time Fault Notifications for Quick Resolution

Receive instant notifications for any equipment faults, powered by AI anomaly detection, ensuring quick resolution and minimizing impact on your production schedule.

Smart Defect Prevention Analysis for Enhanced Product Quality

Analyze defects using AI-driven predictive models to prevent recurrence, improve overall product quality, and enhance customer satisfaction with reliable production processes.

AI-assisted Continuous Improvement for Sustained Operational Excellence

Embed continuous improvement into your operations by using AI-driven real-time data analysis and insights to drive ongoing enhancements in efficiency and quality.

Voices of Our Valued Clients

MaintWiz helps us maximize OEE, ensuring optimal machine performance and minimizing downtime.

OEE tracking through MaintWiz has provided us with actionable insights for continuous improvement.

With MaintWiz, we've achieved outstanding OEE scores, maximizing our production output and efficiency.

MaintWiz provides real-time OEE data that empowers us to optimize every aspect of production.

Through MaintWiz’s OEE module, we've made data-driven decisions to boost productivity and reduce waste.

MaintWiz has helped us dramatically improve OEE, aligning efficiency with productivity goals.

OEE analysis through MaintWiz enables us to continuously optimize machine performance

MaintWiz’s OEE tracking system has led to a substantial improvement in our overall equipment effectiveness.

Maximize Return on Investment (ROI) with AI-Driven OEE Solutions

Harness the power of AI to optimize equipment utilization, close performance gaps, and drive substantial cost savings across your manufacturing operations.

AI-Optimized Equipment Utilization for Peak Asset Performance

Ensure that your assets are available and functioning at peak capacity using AI-driven optimization, delivering the highest possible return on your investment.

AI-Powered Performance Gap Analysis for Continuous Improvement

Identify and close gaps between actual and ideal performance using AI analytics, enhancing operational efficiency and reducing costs.

AI-Driven Production Rate Optimization for Enhanced Profitability

Continuously optimize production rates using AI algorithms to achieve higher throughput, improving profitability and meeting customer demands more effectively.

Intelligent Performance Loss Diagnostics for Minimized Downtime

Diagnose and address performance losses promptly using AI-powered predictive maintenance, maintaining high productivity and reducing unplanned downtime.

AI-Enhanced Defect Cost Reduction for Improved Product Quality

Reduce costs associated with defects by improving first-pass yields through AI-driven quality control, minimizing rework, and enhancing overall product quality.

Intelligent Energy Tracking for Sustainable Manufacturing

Track and optimize energy losses across your operations using AI-powered energy management systems to reduce costs and improve environmental sustainability.

Return on Investment

Maximize productivity and efficiency with our robust OEE solution. Whether in discrete, process, or batch manufacturing, our solution offers real-time insights, enabling you to optimize every aspect of your operations for peak performance. Improve efficiency, minimizes downtime, and ensures continuous improvement across your production lifecycle.

Maximized Equipment Utilization

Ensure that your assets are available and functioning at peak capacity, delivering the highest possible return on your investment.

Performance Gap Analysis

Identify and close gaps between actual and ideal performance, enhancing operational efficiency and reducing costs.

Production Rate Optimization

Continuously optimize production rates to achieve higher throughput, improving profitability and meeting customer demands more effectively.

Performance Loss Diagnostics

Diagnose and address performance losses promptly, maintaining high productivity and reducing unplanned downtime.

Defect Cost Reduction

Reduce costs associated with defects by improving first-pass yields, minimizing rework, and enhancing overall product quality.

Energy Tracking

Track and optimize energy losses across your operations to reduce costs and improve environmental sustainability.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.