Enhance Asset Reliability with Advanced Condition Monitoring Solutions

MaintWiz CMMS empowers you with cutting-edge condition monitoring tools, ensuring real-time asset health insights, predictive maintenance, and reduced operational risks. Connect with IoT Sensors, SCADA, DCS, MES etc. to gain unified view. Excel by optimizing asset performance and minimizing unplanned downtime.

Condition Monitoring

Dive into Detailed Product Information and address your common queries.

Speak to a Specialist

Get personalised advice from our experts

Revolutionize Maintenance with AI-Powered Condition Monitoring

MaintWiz CMMS empowers you with cutting-edge condition monitoring tools, leveraging artificial intelligence to deliver real-time asset health insights, predictive maintenance, and reduced operational risks. Seamlessly connect with IoT Sensors, SCADA, DCS, and MES for a unified view, enabling you to excel by optimizing asset performance and minimizing unplanned downtime.

Intelligent Asset Health Monitoring for Proactive Maintenance

Harness the power of AI-driven real-time monitoring to transform your maintenance strategy, predict failures, and maximize asset reliability.

Real-Time Asset Health Monitoring with AI-Enhanced Data Analysis

Ensure uninterrupted monitoring of asset conditions with continuous data flow, providing real-time analysis for swift decision-making.

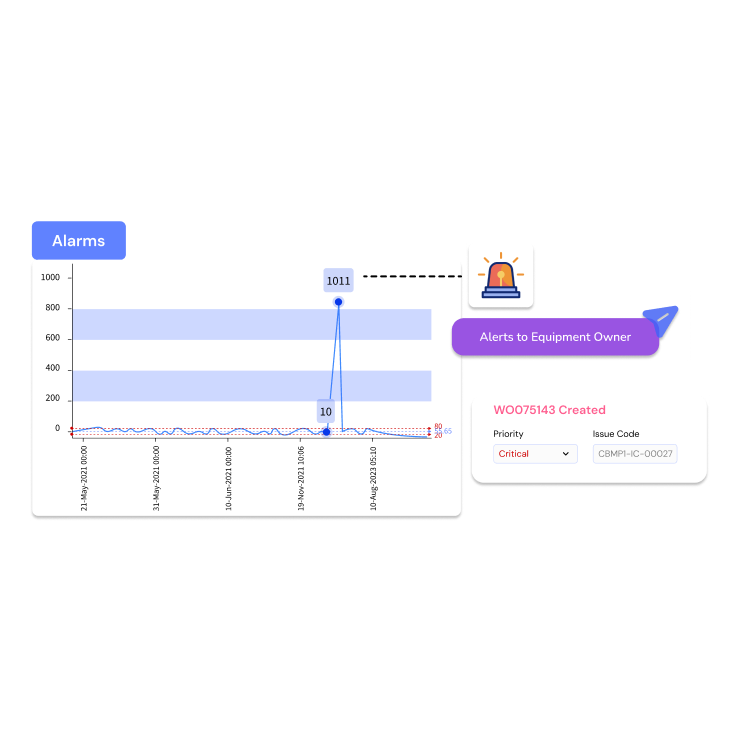

Intelligent Alerts for Predictive Maintenance

Receive instant notifications when assets deviate from standard operating conditions, allowing for prompt corrective actions to avoid failures.

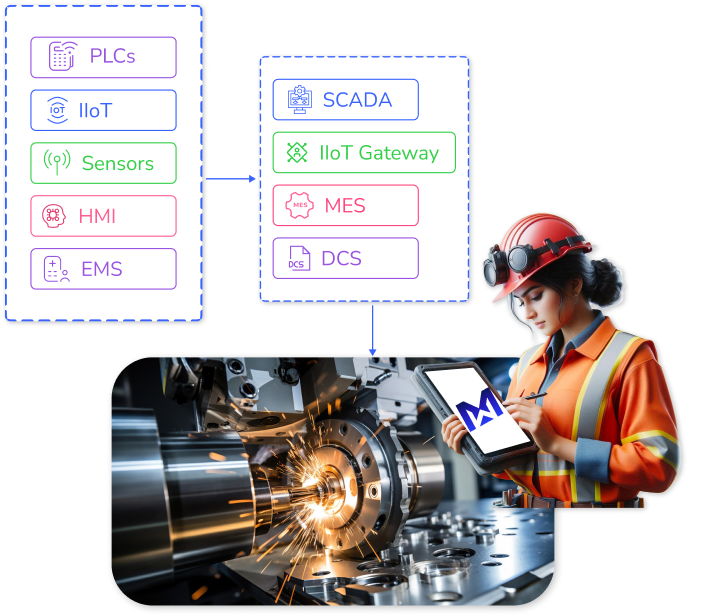

IoT and AI Integration for Comprehensive Asset Monitoring

Leverage IoT-enabled sensors and artificial intelligence for a detailed and holistic view of asset health, enabling smarter, data-driven maintenance strategies and advanced predictive analytics.

AI-Powered Asset Health Reports for Proactive Maintenance Planning

Access AI-generated, in-depth reports on asset conditions to schedule proactive maintenance, reducing the risk of unexpected breakdowns and extending asset life.

Machine Learning-Enhanced Historical Data Analysis

Track historical performance data using machine learning algorithms to identify patterns and predict future asset behavior, supporting more accurate maintenance planning.

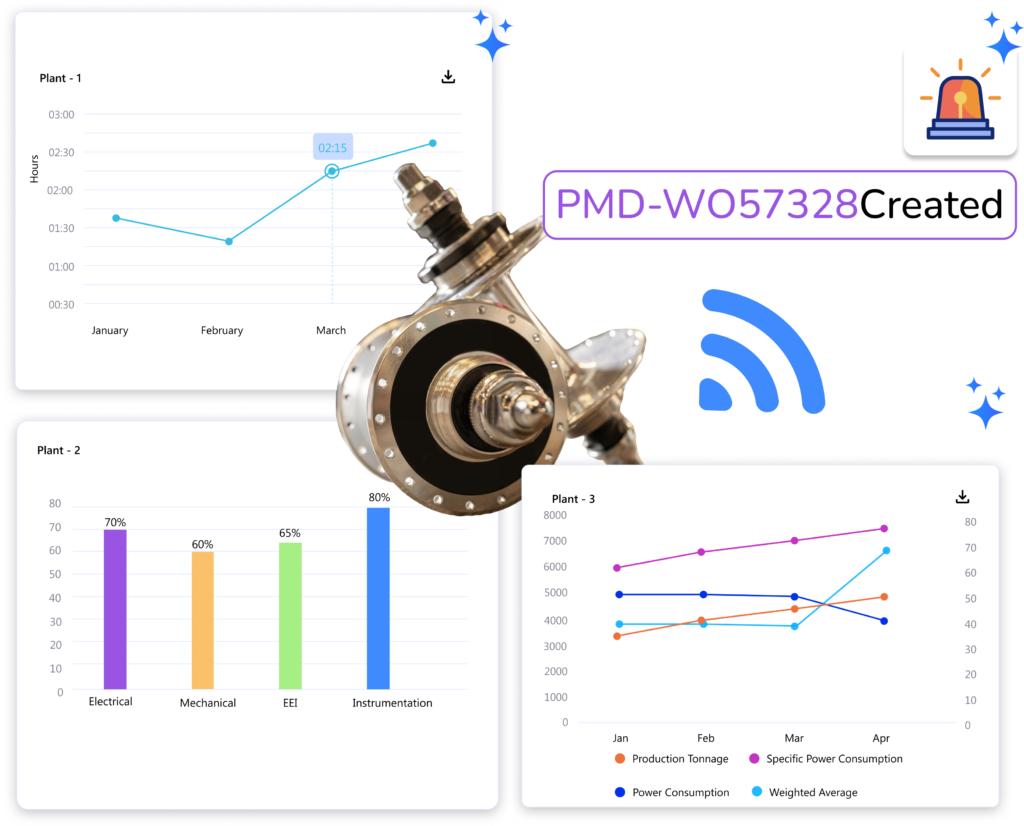

AI-Driven Customizable Dashboards for Intelligent Status Updates

Create personalized, AI-powered dashboards to quickly assess the health of all assets, ensuring you stay informed with real-time status updates and predictive insights.

Top Companies in India & Abroad Trust MaintWiz CMMS

Advanced Condition Monitoring Technologies for Comprehensive Asset Management

Explore our suite of AI-enhanced monitoring technologies designed to provide unparalleled insights into your asset health and performance.

AI-Assisted Vibration Analysis for Early Fault Detection

Identify early signs of mechanical issues through AI-powered vibration analysis, allowing for timely interventions to prevent costly failures.

Intelligent Infrared Thermography for Heat Anomaly Detection

Detect heat anomalies that indicate potential problems with AI-enhanced infrared thermography, ensuring proactive measures before critical failures occur.

Advanced Ultrasonic Testing with Machine Learning

Use ultrasonic testing augmented by machine learning algorithms to uncover hidden flaws in equipment, enabling preventive maintenance actions before issues escalate.

AI-Driven Oil Analysis for Predictive Lubrication Management

Monitor lubrication quality and detect contaminants through AI-powered oil analysis, reducing wear and extending the life of critical machinery.

Intelligent Motor Current Analysis for Electrical Fault Prediction

Analyze motor current using AI algorithms to identify electrical issues early, preventing motor failures and ensuring uninterrupted operations.

AI-Enhanced Corrosion Monitoring for Long-Term Asset Integrity

Track corrosion levels with AI-powered monitoring systems to prevent structural failures and optimize maintenance schedules, ensuring long-term asset integrity.

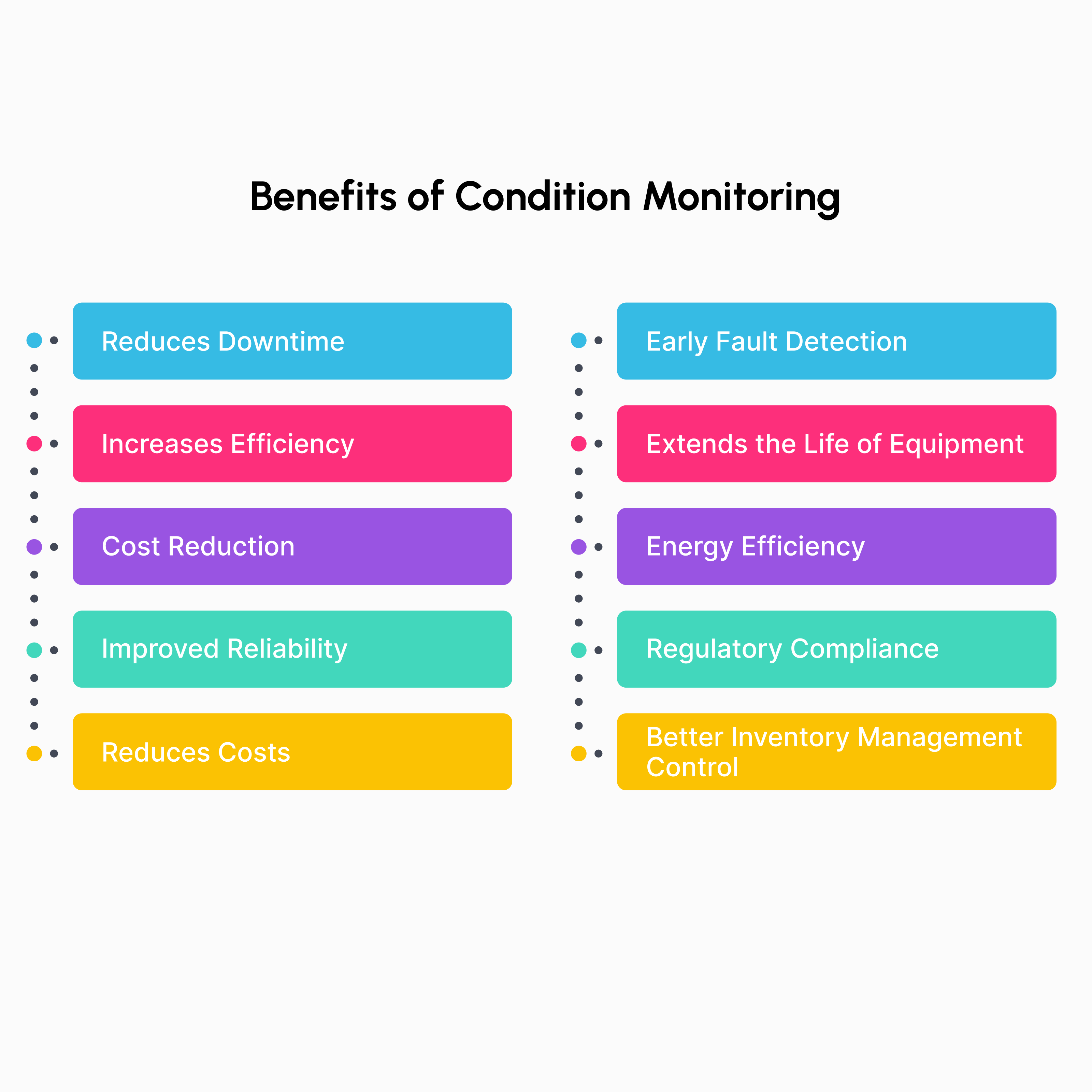

Our Benefits

AI-Powered Condition-Based Maintenance for

Optimal Asset Performance

Leverage artificial intelligence to revolutionize your maintenance approach, optimizing schedules and maximizing asset longevity

AI-Optimized Condition-Based Maintenance Scheduling

Schedule maintenance activities based on real-time condition data and AI-driven insights from IoT sensors, optimizing resources and minimizing unnecessary equipment failures.

Predictive Interventions for Reduced Downtime

Reduce unexpected downtime by addressing issues promptly, maintaining continuous operations and enhancing overall productivity.

AI-Powered Insights for Advanced Maintenance Strategies

Leverage AI-driven, data-driven insights to refine and improve proactive and predictive maintenance strategies, ensuring higher efficiency and cost savings.

Machine Learning for Enhanced Failure Forecasting

Utilize historical data and machine learning algorithms to improve forecasting accuracy and predict failures, leading to better planning and reduced maintenance costs.

AI-Driven Maintenance Schedule Optimization

Optimize maintenance schedules with AI-powered predictive analytics, ensuring timely interventions and maximizing asset lifespan.

Advanced AI Algorithms for High-Precision Predictive Maintenance

Employ state-of-the-art AI algorithms to predict failures with high accuracy, allowing for preventive actions before issues occur and minimizing unplanned downtime.

Voices of Our Valued Clients

Seamless CMMS Integration for AI-Enhanced Operations

Experience the power of AI-driven integration between condition monitoring systems and CMMS for unparalleled operational efficiency and decision-making.

AI-Powered Data Flow Between Monitoring Systems and CMMS

Ensure smooth data transfer between monitoring systems (IoT Sensors, SCADA, DCS) and CMMS, leveraging AI for cohesive maintenance management and intelligent decision-making.

AI-Driven Automated Work Order Creation

Automate work order generation from condition data using AI algorithms, reducing manual effort and speeding up response times for maintenance activities.

AI-Enhanced Risk-Based and Condition-Based Inspections

Conduct inspections based on AI-analyzed risk and condition data, improving safety and reducing unnecessary inspections through intelligent prioritization.

AI-Powered Asset Lifecycle Management with Integrated Insights

Enhance asset lifecycle management with AI-driven integrated insights, leading to better decision-making and long-term asset value optimization.

AI-Assisted Reporting and Multi-Dimensional Analysis

Simplify reporting and detailed analysis with AI-powered multiple perspectives, enabling quicker access to critical information and actionable insights.

Intelligent Collaboration Between Maintenance and Monitoring Teams

Foster better collaboration between maintenance and monitoring teams with AI-integrated systems, improving overall operational efficiency and decision-making processes.

Elevate Operational Excellence: Leverage Condition Monitoring for Superior Maintenance

Transform your maintenance approach with advanced Condition Monitoring. Gain real-time insights and proactive alerts to elevate operational efficiency and reduce downtime. Our solution ensures peak performance and maximizes equipment reliability, paving the way for a more productive and cost-effective operation.

IoT Integration

Get real time insights into equipment status through IoT sensors integration

Proactive Maintenance Solutions

Shift from reactive to proactive with innovative maintenance strategies.

Equipment Reliability

Boost reliability with advanced tools and techniques for equipment management.

Condition-Based Maintenance

Adopt condition-based maintenance to address issues based on equipment performance data.

Preventive Maintenance

Comprehensive preventive maintenance scheduling for improved operational efficiency

Work Order Management

Streamline work orders to enhance maintenance workflow and operational efficiency.

Predictive Maintenance

Optimize your approach with predictive analytics for smarter maintenance decisions.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.

MaintWiz’s Condition Monitoring transformed our maintenance strategy, enhancing reliability and efficiency