Unlock the Future of Asset Management with Predictive Maintenance

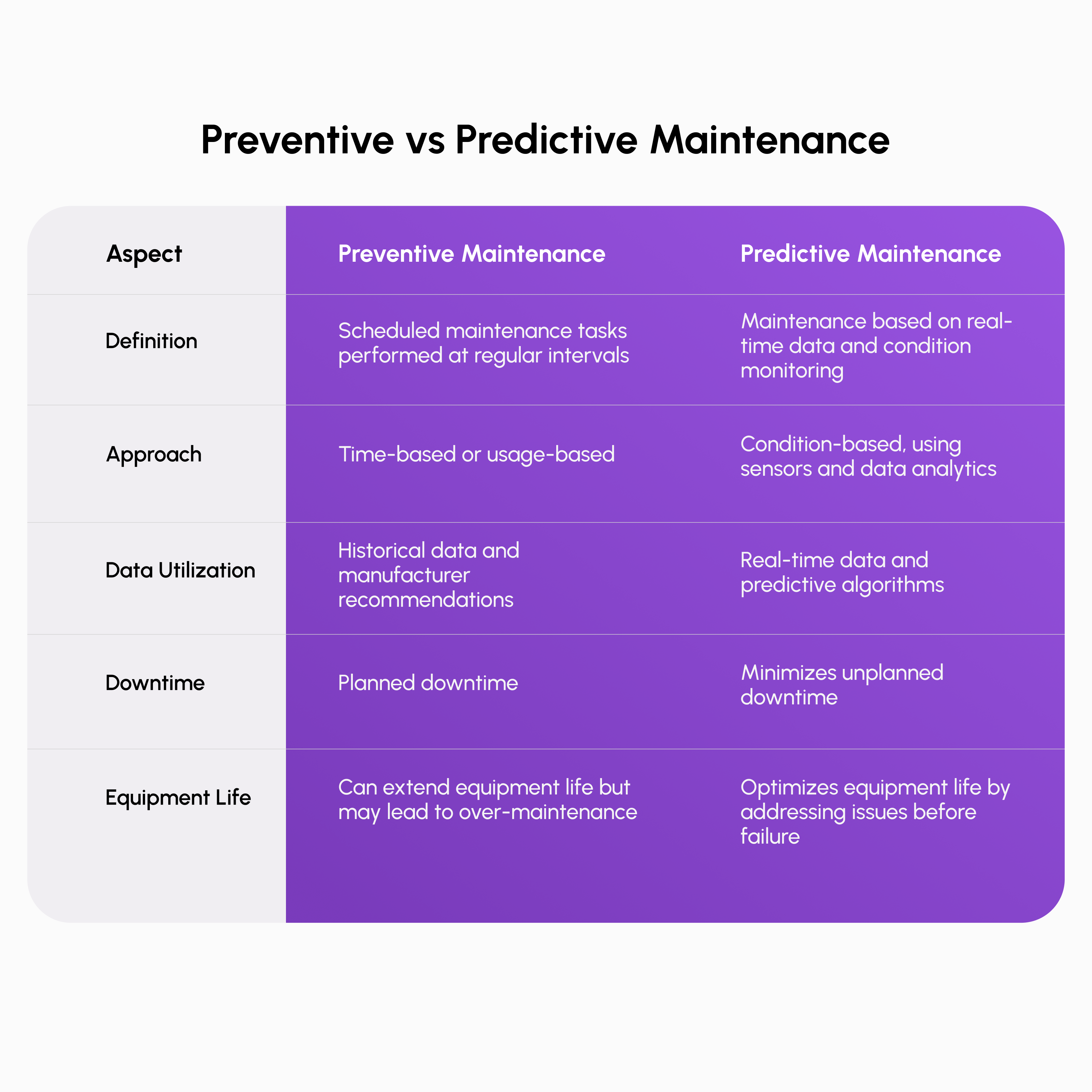

Experience unparalleled operational efficiency and cost savings with MaintWiz CMMS's state-of-the-art predictive maintenance solutions. Utilizing advanced algorithms, real-time monitoring, and AI-driven insights, MaintWiz enhances equipment reliability, reducing unexpected downtime and boosting overall asset performance.

Predictive Maintenance

Dive into Detailed Product Information and address your common queries.

Speak to a Specialist

Get personalised advice from our experts

Comprehensive Predictive Maintenance Solutions for Optimal Equipment Performance

Revolutionize your asset management strategy with MaintWiz CMMS's AI-powered predictive maintenance. Our cutting-edge solutions leverage advanced algorithms and machine learning to maximize equipment reliability, minimize downtime, and optimize maintenance costs.

Advanced AI Algorithms for Precision Forecasting and Breakdown Prevention

MaintWiz CMMS employs sophisticated predictive models to analyze real-time and historical data, providing accurate forecasts of potential equipment failures. This proactive approach significantly reduces unexpected downtime and maintenance costs.

Transform Raw Data into Actionable Insights with AI-Driven Predictive Analytics

Our powerful predictive analytics engine processes vast amounts of operational data to identify maintenance needs before they become critical issues. This ensures optimal equipment reliability and extends asset lifecycles, reinforcing effective asset management practices.

Enhance Equipment Reliability Through AI-Powered Failure Mode Analysis

MaintWiz CMMS’s failure mode analysis capability allows you to predict and prevent potential equipment issues, dramatically improving asset reliability and reducing the risk of unexpected breakdowns.

Leverage Real-Time AI Condition Monitoring for Proactive Component Failure Prediction

Our advanced condition-based monitoring system provides real-time insights into equipment health, enabling you to predict component failures accurately and schedule preventive maintenance activities strategically.

Optimize Spare Parts Inventory with AI-Driven Predictive Insights

MaintWiz CMMS aligns your spare parts inventory with predictive maintenance needs, reducing shortages, overstock and carrying costs, and ensuring critical components are available when needed.

Implement Adaptive Maintenance Strategies with Machine Learning

Adjust your maintenance strategies based on AI-powered predictive analytics, derived from real-time and historical data analysis. Extend the life of your machinery with timely, proactive interventions and optimized maintenance schedules.

Top Companies in India & Abroad Trust MaintWiz CMMS

Real-Time Data Monitoring for Unparalleled Asset Visibility and Performance Optimization

Gain unprecedented insights into your assets' health and performance with MaintWiz CMMS's AI-enhanced real-time monitoring capabilities. Our intelligent system continuously analyzes data to provide actionable information, enabling proactive decision-making and optimized asset management.

Track Equipment Status in Real-Time with AI-Powered IoT and OT Integration

MaintWiz CMMS integrates seamlessly with IoT sensors and operational technology, providing real-time visibility into your equipment’s status and performance metrics for informed decision-making.

Ensure Data Accuracy with AI-Driven Real-Time Synchronization Capabilities

Our platform’s real-time data synchronization ensures that all predictive models and decision-making processes are based on the most up-to-date and accurate information available.

Uncover Hidden Patterns in Equipment Performance with AI and Machine Learning

MaintWiz CMMS’s AI and ML-powered advanced analytics engine identifies subtle trends and patterns in equipment performance, enabling you to address potential issues before they result in major failures.

Correlate Current Operational Data with Historical Failure Trends Using AI

By comparing real-time operational data with historical failure trends, MaintWiz CMMS provides highly accurate predictions of potential equipment issues, allowing for timely preventive actions.

Detect and Address Anomalies Proactively with AI-Powered Monitoring Algorithms

MaintWiz CMMS employs smart algorithms to detect deviations from normal operating conditions, identifying equipment deterioration and component failures early to prevent unexpected downtime.

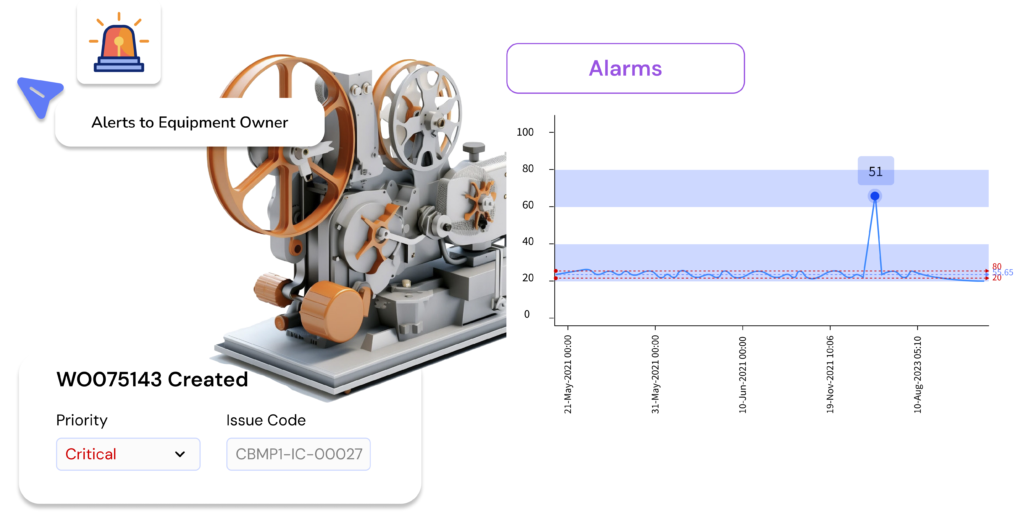

Stay Informed with AI-Generated Alerts and Mobile-Friendly Equipment Status Updates

Receive instant notifications about potential issues and monitor equipment status on-the-go with our mobile-friendly platform, ensuring you’re always in control of your asset management and maintenance strategy.

Our Benefits

Implement Effective AI-Driven Predictive Maintenance with Ease

Seamlessly integrate AI-powered predictive maintenance into your operations with MaintWiz CMMS. Our user-friendly platform and expert support ensure a smooth transition to data-driven, proactive asset management, maximizing your ROI and operational efficiency.

Define Clear Objectives and Identify Critical Assets for AI-Optimized Performance

MaintWiz CMMS helps you establish clear goals, identify mission-critical assets, and set appropriate KPIs and thresholds for effective predictive maintenance implementation.

Select the Right AI Tools and Technologies for Comprehensive Data Collection

Our platform integrates with various data sources, including IoT sensors, PLCs, SCADA, and MES systems, ensuring you have the right tools to collect and analyze real-time condition monitoring data.

Leverage Advanced AI Predictive Algorithms and Models for Accurate Forecasting

MaintWiz CMMS facilitates applying AI-powered predictive algorithms and machine learning (ML) models, providing you with highly accurate maintenance forecasts and recommendations for optimal asset performance.

Empower Your Team with AI-Focused Training and Expert Support

We provide thorough training and ongoing support to ensure your staff can fully leverage the power of MaintWiz CMMS’s predictive maintenance capabilities, enhancing equipment reliability and operational efficiency.

Continuously Evaluate and Optimize Your AI-Driven Predictive Maintenance Strategy

Our platform allows you to monitor predictive maintenance results, benchmark against industry standards, and easily adjust strategies to ensure continuous improvement and optimized asset performance.

Foster a Culture of AI-Driven Continuous Improvement in Asset Management

MaintWiz CMMS supports ongoing refinement of predictive models, incorporates user feedback, and integrates emerging technologies like AI, ML and Digital Twin, to keep your maintenance strategies at the cutting edge.

Voices of Our Valued Clients

Harness the Power of Advanced AI and ML for Superior Asset Management

Elevate your asset management strategy with MaintWiz CMMS's state-of-the-art AI and ML capabilities. Our innovative platform leverages cutting-edge technologies to provide unparalleled insights, enabling data-driven decisions that optimize asset performance and reliability.

Enhance Predictive Monitoring with Advanced Artificial Intelligence Capabilities

MaintWiz CMMS leverages cutting-edge AI technologies to provide unparalleled predictive monitoring capabilities, ensuring optimal asset performance and minimizing unexpected downtime.

Improve Prediction Accuracy with Sophisticated Machine Learning Algorithms

Our platform employs advanced machine learning (ML) algorithms to continuously refine and improve prediction accuracy, allowing for more precise maintenance scheduling and resource allocation.

Unlock Deep Insights with State-of-the-Art Deep Learning Technologies

MaintWiz CMMS incorporates deep learning capabilities to uncover complex patterns and relationships in your maintenance data, providing unprecedented insights for strategic decision-making.

Simulate and Analyze Maintenance Scenarios with AI-Powered Digital Twin Technology

Our Digital Twin technology allows you to create virtual replicas of your assets, enabling comprehensive scenario analysis and optimization of maintenance strategies without risk to physical equipment.

Integrate Big Data for AI-Driven Comprehensive and Accurate Predictive Analysis

MaintWiz CMMS seamlessly integrates big data from multiple sources, providing a holistic view of your assets and enabling more accurate and comprehensive predictive maintenance analysis.

Visualize Complex Predictive Data with AI-Enhanced Analytical Tools

Our platform offers advanced data visualization tools and interactive dashboards, that transform complex predictive maintenance data into clear, actionable insights, empowering informed decision-making at all levels of your organization.

Achieve Peak Asset Reliability with Advanced Predictive Maintenance Solutions

Discover our comprehensive, predictive management solutions. Empower your team with actionable insights to enhance equipment reliability. Prevent costly breakdowns, extend asset lifespan, and reduce maintenance costs through real-time data monitoring and automated alerts.

Breakdown Maintenance

Minimize downtime with fast, reliable response to unexpected equipment failures.

Work Order Management

Simplify work orders to enhance maintenance workflows and productivity.

Condition Monitoring

Monitor equipment conditions in real-time to predict potential failures early.

Internet of Things (IoT)

Leverage IoT technology to gather real-time data for smarter maintenance decisions.

Energy Management

Reduce energy consumption and costs by optimizing asset energy efficiency.

Asset Intelligence

Utilize AI-driven insights to make smarter decisions on asset maintenance and performance.

Digital Twin Technology

Simulate asset performance and maintenance scenarios using digital twin technology.

Maintenance Budgeting

Effectively manage and control your maintenance budget to maximize ROI.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.

MaintWiz Predictive Maintenance has revolutionized our operations, cutting unplanned downtime by 40%.