Instrument Calibration to

Achieve Accuracy

Table of Contents

ToggleInstruments & Calibration Process

What are Instruments?

An instrument is a measuring device for determining the present condition of the observed parameter. Examples of instruments include pressure gauges, weigh scales, and spectroscopy meters, Scale of the instruments usually conform to international standards (e.g., International System of Units / SI System of measurement) and thus the measured values are on standard units of measurement. Some instruments have dual scales (e.g. Pound and kg) to support different standards of measurement or technical specifications.

Plants need to monitor multiple parameters relating to input and output, operating conditions, quality, technical specifications of finished goods etc. Many different types of instruments and measuring devices are used across the manufacturing plant for the measurement of these critical parameters. These instruments can be inline, i.e., built as part of the equipment or stand-alone. Instruments can have single functionality (pressure gauge) or multiple functionalities (e.g., Multimeter) or hybrid with multiple functionalities, multiple ranges etc. (e.g., Oscilloscope)

What is Instrument Calibration?

Calibration is the process of comparing the readings of an instrument against known standard values of the measures under specified conditions and adjusting the controls of the instrument, to improve accuracy. The calibration process involves evaluating and adjusting the precision and accuracy of the measuring instrument. A calibrated (recalibrated) instrument will have measures that are accurate and within specified tolerance levels under the specified conditions.

Calibration involves checking measures at several points between the min and max range of the instrument, usually in pre-defined increments, and comparing against standard values. The calibration range is defined as the span between the limits within which the target parameter is measured.

Calibration of the target instrument will be done against a master instrument (standard instrument). Measurements of the master instrument used should be traceable with an unbroken chain of comparison with higher level reference standards up to known national or international standards.

The instrument calibration process ensures that the measurements are predictable, accurate and reliable and conform to the quality standards and technical specifications of the measuring device. Manufacturing plants will have instrumentation teams under the plant maintenance function or as a separate department. Instrumentation teams act as custodians of instruments and measuring devices, and for the integrity of their measurements. Instrumentation teams manage all instrument-related work and calibrations, including repairs and instrument maintenance, instrumentation vendors coordination and statutory compliance.

Types of Instrument Calibration

Measuring devices and instruments vary based on the parameters they are designed to measure. The standard instruments for each test device and calibration procedure may vary accordingly. Some of the instrument calibration types are given below

| S.No. | Instrument Calibration Type | Specific Examples of Instruments | Parameters |

|---|---|---|---|

| 1 | Electrical Calibration | • Ammeter, Voltmeters, Wattmeter, Multi-meter • Clamp Meters • Counter timers • Data Loggers • Electrical meters • Insulation Testers • Loop Testers • Phase angle meters • Oscilloscopes • RCD | • Current • Voltage • Power • Phase-angle |

| 2 | Mechanical Calibration | • Accelerometers • Load Cells & Force Gauges • Micrometers, Verniers, Height Gauges • Scales/Balances • Torque Wrenches & Screwdrivers • Weight & Mass Sets | • Mass • Force • Flatness • Torque • vibration |

| 3 | Electronic Calibration / Digital Calibration | • Smartmeters • Digital Multi-meters • Digital Oscilloscopes • Infrared Wave instruments • Electronic level indictors • Smart Actuators | • Signals • Voltage |

| 4 | Pressure Calibration | • Analogue Pressure Gauges • Barometers • Digital Indicators • Digital Pressure Gauges • Test Gauges • Transmitters | • Pressure |

| 5 | Temperature Calibration | • Chambers/Furnaces • Data Acquisition Systems • Dial Thermometers • Infrared Meters • PRTs and Thermistors • Thermal Cameras • Thermometers/Thermocouples • Weather Stations | • Temperature |

| 6 | Measurement Calibration / Flow (Volume) Calibration | • Scales • Theodolite • Electronic Distance Measurement instrument (EDM) • Automatic level • Laminar Flowmeters • Rotometers – Gas and Air • Thermal Mass Flowmeters • Turbine Meters | • Dimension • Angle • Volume • Volume / quantity • Quality • Energy consumption • Safety release |

Why do we need Instrument Calibration?

Instruments are used for measuring parameters. The integrity of measurement is vital. These measurements being accurate are critical for ensuring equipment performance and upkeep, product quality and safety. Eliminating or minimizing factors that cause inaccurate measurements is a fundamental goal of the instrumentation department.

Inaccurate measurements can cause safety hazards, equipment damage, component failure, wastage, energy inefficiencies, defective products etc. Safety of people relying on erroneous measurements is at risk. And such erroneous readings may give misleading information to production and maintenance staff, leading to errors. Certain instruments and their measurements may be governed by legal and/or industry regulations and compliance with these regulations is mandatory.

Calibration reduces instrument measurement errors. Instrument calibration is required for

- Observance of any deviations in measurements and rectification of such measurement errors

- To improve the reliability of the system/process under the measure

- To meet statutory requirements and ensure consistency with standard measurements

- With prolonged usage, instruments tend to drift from accurate measurements and such measuring devices need adjustment. Calibration improves measurement accuracy and instrument precision.

- When the instrumentation team repairs or modifies an instrument, it needs to be calibrated again, to ensure error reduction and improvement of measurement accuracy.

- When the instrument measurements are not aligned with other secondary readings/surrogate measurements, the instrumentation team should initiate calibration of such instruments.

Type of calibration shown above is not exhaustive and illustrated for understanding. Depending on the type of industrial process, operating environment and technical requirements, a wider variety of instruments are used.

Instrument Calibration Terminology:

Calibration Frequency:

Calibration frequency defines the number of times the instrument needs to be calibrated over a defined period.

Calibration Interval:

Calibration interval defines the time period between successive calibrations of the same instrument.

Calibration Range:

The calibration range is defined as the span between the limits within which the target parameter is measured. The point to note is the distinction between the range in which the instrument is capable of operating versus the range in which the instrument has been calibrated. The instrument range may be wider and as per the make and model. The instrument range will be specified in the nameplate and as well in technical specifications. The calibration range will be more defined by the purpose and operating conditions. The instrument range will be wider than the Calibration range.

Calibration Tolerance:

Permissible deviation that is allowed from the defined value (standard value). It can be expressed in units of measurement for the specified parameter or as a percentage of deviation from the standard measurement.

Calibration Error:

Difference between the standard value of measurement and the observed value of measurement.

Accuracy:

The ratio of the error to the full-scale output is usually expressed in percentages.

Least Count:

Sometimes referred to as Sensitivity or Resolution is the smallest value that can be measured on the scale of the instrument. Any measured value by the instrument is good only up to this least count. The least count is usually expressed in the unit of measurement of the target parameter.

The least count is inversely related to the precision of the instrument i.e., the lower the least count, the higher the precision of the instrument.

Least Count Vs Accuracy:

The least count is the smallest value on the scale of the instrument. It indicates the smallest value that the instrument can measure. Accuracy indicates how close the measured value is to the actual value.

Accuracy Vs Error:

Accuracy is the degree of closeness to the standard value. Error is the difference between the standard value and measured value.

Noise:

Noise is a random variation in calibration measurements due to external factors.

Instrument Calibration Process:

Instrument calibration should follow a consistent, repeatable and validated process that ensures the desired results in terms of accuracy of measurements. A good instrumentation calibration process should also ensure that the results are traceable to known national or international standards. National Institute of Standards and Technology (NIST) of the United States and the Bureau of Indian Standards (BIS) of India are examples of national standards organizations, that maintain country-level primary standards of measurement.

In theory, the calibration process means only the comparison, but in practice, the term calibration is used to include the comparison of measurements and corrective actions and adjustments as well. Essential elements of the Instrument calibration process include the availability of master instruments whose measurements and traceability, trained staff with relevant domain expertise, training and requisite professional certifications, a process for qualification and validation of instruments, procedures for the measurement of test instrument against standards, pass-fail criteria definitions, corrective actions for adjustments and defect resolution and systems for recording the measurements.

The calibration process can be manual with people letting the calibration process or following an automated process where intelligent instruments can calibrate and adjust the measuring device. Calibration of instruments can also be done as field calibration or bench calibration. In a field Calibration, the instrument is not removed from its fixtures and the testing is carried out on the shop floor and under normal operating conditions. A bench calibration is done in an external environment, using a calibration bench and under simulated conditions. Field calibrations are more accurate and reliable, as they account for the operating conditions, noise, and other external factors.

For analogue instruments and measuring devices, linear calibration is the simplest process. It involves calibrating the lower calibration range and upper calibration range at the middle interval. Five-point calibration is an improvement over linear calibration, and it involves calibration for multiple middle intervals, usually in incremental steps, between the two ends of the calibration range. Five-point calibration can be done with standard readings or at regular percentage intervals between the lower and upper calibration ranges.

Rise and fall calibrations (Or called Up down calibrations involves taking bi-directional readings i.e., 0%, 25%, 50%, 75%, 100% and then 75%, 50%, 25% and 0%. Bi-directional readings point out hysteresis in the measuring devices i.e., differential impact based on direction.

Digital instruments and measuring devices with linear calibration generally support the trimming of sensors at the lower calibration range and upper calibration range to calibrate the instrument. Discrete instruments, like process switches, toggle between On and Off states, depending on the value of the signal being higher or lower than the set point (trip point). Discrete instrument calibration thus involves only one adjustment of the trip point. Based on the type and usage of discrete instruments, calibration procedures may involve bi-directional calibration and deadband adjustments.

Non-linear calibration is a more complex process, since two adjustments may not be sufficient to define the curve for the measuring device. It’s recommended to follow the suggested calibration procedure of the Original Equipment Manufacturer (OEM), for these measuring devices.

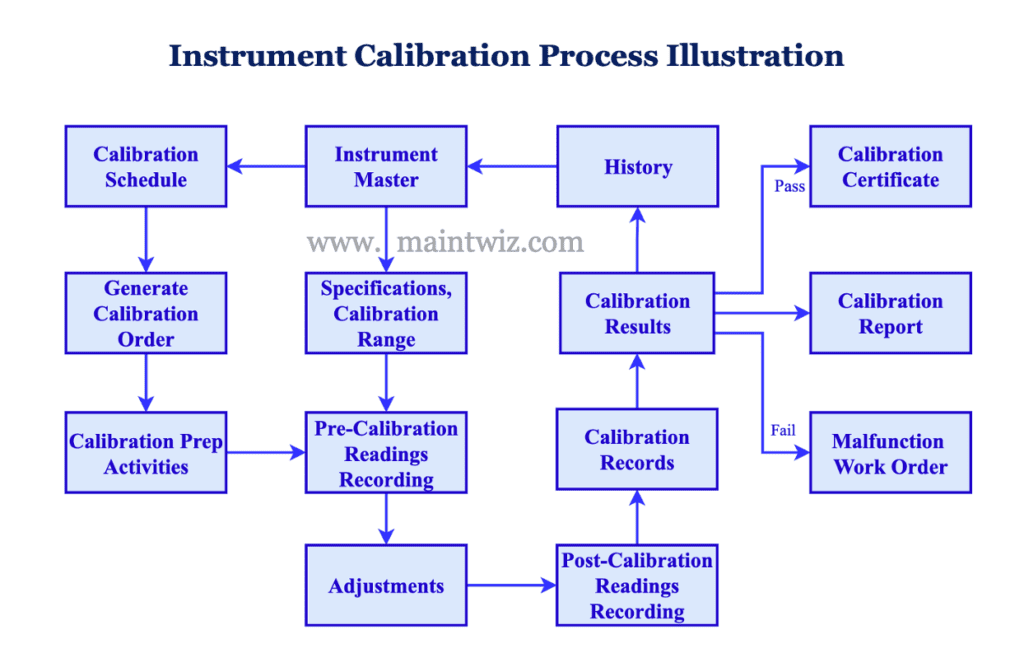

A step-by-step process that defines the principal activities required for instrument calibration is illustrated herein.

Instrument Specifications:

OEM (Original Equipment Manufacturer) defined specifications are outlined in the technical documentation of the instrument. Most manufacturers provide details on reference standards or master instruments (standard instruments or reference instruments) against which calibration of the measuring device needs to be done. Such details are usually captured as part of Instrument Master in CMMS Software, Calibration Software, or other supporting IT systems and are made available as a reference to the Instrumentation team.

Scheduling:

Calibration for the measuring device needs to be repeated periodically based on regulatory compliance, industry norms or organization standards. The scheduling engine can ensure that the requisite calibration order is generated on time so that the instruments won’t become non-compliant.

Calibration Orders:

A list of tasks to be performed on the instrument or measuring device and readings that need to be taken to compare the readings against standard. Calibration orders also have provisions to capture the readings and final recommendations as “fit-for-use” by the Calibration technician.

Preparatory Activities:

List of tasks to be performed on the instrument or measuring device prior to recording the calibration readings.

Pre-Calibration Readings:

Readings of the instrument are measured over the range of calibration and usually in incremental steps. These readings will be compared against the standard readings. If deviations are observed, corrective actions to adjust the instrument will be initiated.

Adjustments:

If the calibration error is more than the allowed calibration tolerance levels, then suitable adjustments and other corrective actions are performed on the measuring device.

Post-Calibration Readings:

Readings of the instrument are measured over the range of calibration and usually in incremental steps, carried out after the corrective actions are executed. These readings will be compared against the standard readings to determine fitness for usage.

Calibration Results:

Calibration results will be either Pass or Fail, indicating their fitness for usage or not. Accuracy of the post-calibration readings and assessment over another pass / fail criteria laid out will be used to determine if the instrument is fit for usage. Sometimes the due date for the next calibration service will also be defined.

Calibration Records:

All the documentation associated with the instrument calibration including checklists, Standard Operating Procedures (SoP), and recorded measurements, forms part of calibration records. Calibration records are usually stored in CMMS Software or Calibration Management Software.

Calibration Report & Calibration Certificate:

The calibration report contains all the details of the calibration including instrument details, date, calibration procedures, readings, recommendations etc. If fit for usage, a calibration certificate can be generated with all the details. Usually, calibration certification generation is preceded by a review and approval of the calibration process and readings. Certificates of calibration assure the user group of the fitness for use and conformance of results to specifications.

Malfunction Reporting:

If the faulty instrument or measuring device can be set-right, then an Instrument Work Order will be generated with the malfunction details and sent for repair.

History:

Instrument history will have records relating to the past calibrations, the readings there-on, and the recommendations. The calibration Order history will capture all the work that was done once the calibration order was initiated.

The instrument Calibration process can be done in-house by the instrumentation team, or by outsourcing to specialized vendors having accredited calibration laboratories with sophisticated instruments. The instrumentation department directs and manages the calibration process and based on the instrument type, criticality and in-house availability of resources/expertise, may choose to do the calibration in-house or outsource.

Calibration Management Software:

Independent Calibration Management Software exists and is used by the instrumentation department to schedule the instrument calibrations and record the measurements. Modern Computerized Maintenance Management Systems (CMMS Software) has Instruments and Calibration as an integral part of the functionalities offered and provides a comprehensive way to schedule instruments, generate calibration orders, define pass / fail criteria, generate calibration certificates (or store vendor certificates), provides instrument analytics and complete instrument history at single place.

Tips for Improving Calibration Process:

- Calibration for different instruments occurs throughout the year. Defining a proper system to capture the calibration requirements, schedules, process, readings, and history will greatly improve the operational efficiency of the instrumentation process.

- Certain instruments need to be calibrated at a specified frequency to ensure statutory compliance (eg. Loadcells). Care should be taken while ascertaining the due date for the next calibration. For example, if an annual statutory calibration is due on 30th June and in a certain year, the calibration exercise has been done in advance and completed on 15th Due date for the next annual calibration for this instrument is 14th June of the following year and not 30th June. Modern CMMS software has readymade features available to calculate the due date for the next calibration after the elapse of specified days from the prior calibration completion date.

- Planning tools help a great deal in improving process efficiency. They provide planning boards with a visual view of all the upcoming calibration orders and, also the tools to adjust the current instance of calibration order, based on the availability of instruments, resources, vendors etc.

- Certain meters can measure multiple parameters simultaneously. While the instrument is the same, calibration range and pass / fail criteria may vary for each of the measurements. The calibration process should be able to capture the pre-calibration and post-calibration readings of the individual meters and in the evaluation of each of these meters. All the measurements in such hybrid meters should be accurate and within the allowed tolerance levels.

- Analytics: A robust system to capture all the past history of the instruments and provide business intelligence and analytics regarding calibration forecasts, overdue items, repeat issues etc.

- Some organizations outsource the instrument calibration process. Vendors provide calibration certificates containing all requisite details, upon completion of work. CMMS systems that have provisions to capture this information and attach certificates from vendors can improve process efficiency.

Calibration is a critical process in the instrument life cycle. Calibration of measuring instruments periodically ensures accuracy of measurements and thus reduces human errors, equipment damages, people safety and hazard prevention. An efficient system to manage the instruments through their life cycle including calibrations will greatly help the plant’s operational efficiency and compliance.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.