MaintWiz AI CMMS: Revolutionizing Paints & Coatings Manufacturing

Boost your paints and coatings production with MaintWiz AI CMMS—optimize assets, streamline maintenance, and enhance quality for unmatched efficiency and excellence.

Transformative Benefits of MaintWiz AI CMMS for Paints Manufacturing

Transformative Benefits of MaintWiz AI CMMS for Paints and Coatings Industry

Discover how MaintWiz AI CMMS revolutionizes paint and coating manufacturing, driving

operational excellence and competitive advantage through intelligent maintenance and asset

optimization.

Enhanced Production Efficiency and Quality Control:

MaintWiz AI optimizes equipment performance, reducing downtime and ensuring consistent product quality across batches.

Predictive Maintenance for Critical Mixing Equipment:

AI-driven insights prevent unexpected breakdowns, maximizing uptime for mixers, dispersers, and other vital machinery.

Streamlined Regulatory Compliance Management:

Automated tracking and reporting ensure adherence to industry standards, simplifying audits and reducing compliance risks.

Intelligent Inventory and Supply Chain Optimization:

AI-powered forecasting ensures optimal stock levels of raw materials, reducing waste and improving production planning.

Data-Driven Decision Making for Continuous Improvement:

Advanced analytics provide actionable insights, driving strategic decisions and fostering a culture of innovation.

Sustainable Manufacturing Practices:

MaintWiz AI supports eco-friendly initiatives by optimizing resource utilization and minimizing waste in paint production.

Top Companies in India & Abroad Trust MaintWiz CMMS

Speak to a Specialist

Get personalised advice from our experts

Why MaintWiz AI CMMS is the Catalyst for Paint Industry Excellence

MaintWiz AI CMMS stands out as the premier solution for paint and coatings manufacturers,

offering unparalleled capabilities tailored to industry-specific challenges and opportunities.

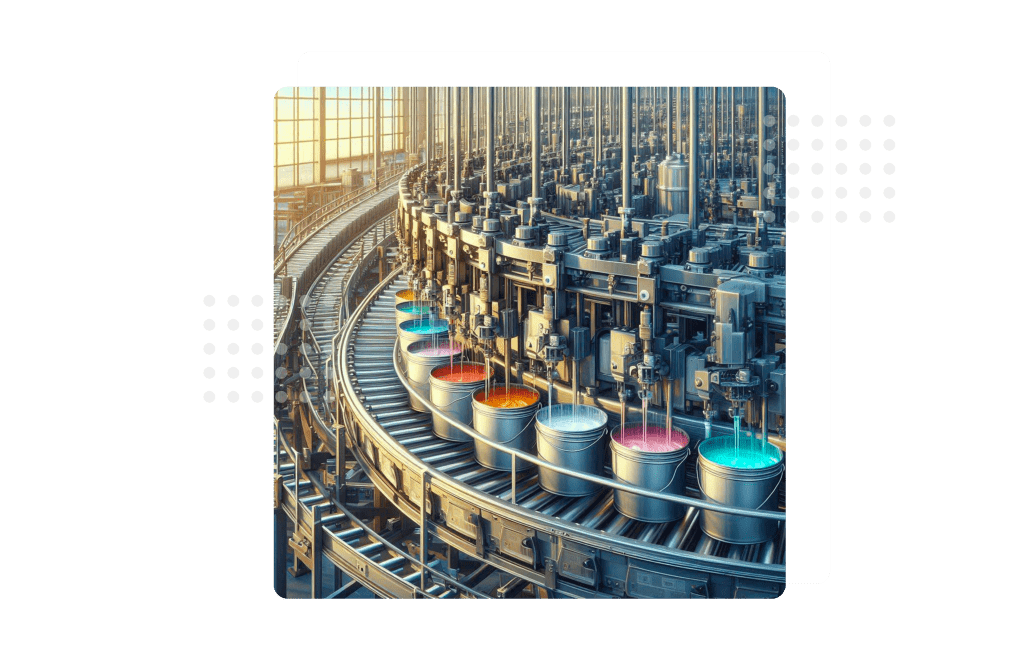

Comprehensive Coverage Across Paint Manufacturing Processes

MaintWiz AI CMMS offers tailored solutions for every stage of paint and coatings

production, ensuring seamless operations and superior product quality from raw materials to

final packaging.

Raw Material Handling:

• Intelligent inventory management for pigments, binders, and additives

• Automated quality checks for incoming materials

Optimized storage conditions monitoring

• Seamless integration with supplier management systems

Mixing and Dispersion:

• Predictive maintenance for high-shear mixers and dispersers

• Real-time monitoring of critical process parameters

• AI-driven optimization of mixing times and energy consumption

• Automated batch record keeping and traceability

Quality Control and Testing:

• AI-powered analysis of in-process and final product testing

• Automated compliance checks with industry standards

• Trend analysis for continuous quality improvement

• Integration with spectrophotometers and other testing equipment

Packaging and Distribution:

• Optimized maintenance schedules for filling and packaging lines

• Real-time tracking of product inventory and shipments

• Automated label verification and regulatory compliance

• Predictive analytics for demand forecasting and production planning

Seamless Integration Ecosystem for Paint Manufacturing Excellence

MaintWiz AI CMMS offers a robust integration platform, connecting your paint production

systems for unprecedented operational synergy and intelligence.

ERP and MES Integration for Holistic Operations:

Seamlessly connect MaintWiz with SAP, Oracle, or custom ERP systems, ensuring real-time

data flow between maintenance, production, and business operations.

IoT-Enabled Predictive Maintenance:

Harness data from connected sensors on mixing equipment, spray booths, and curing ovens to

predict failures and optimize maintenance schedules.

Quality Management System (QMS) Synchronization:

Integrate with leading QMS platforms to ensure seamless quality control, from raw material

testing to final product validation.

Advanced Analytics for Strategic Insights:

Leverage MaintWiz AI-driven analytics engine to extract actionable insights from

production data, driving continuous improvement in paint manufacturing processes.

Enhance paint manufacturing efficiency with MaintWiz AI CMMS while ensuring consistent quality

Overcoming Paint Industry Challenges with AI- Powered Maintenance

MaintWiz AI CMMS addresses critical pain points in paint and coatings manufacturing,

transforming challenges into opportunities for operational excellence and market leadership.

Volatile Raw Material Costs and Supply Chain Disruptions:

AI-driven inventory optimization and supplier management mitigate risks associated with fluctuating raw material prices and availability.

Rapidly Evolving Consumer Preferences and Market Trends:

Agile maintenance and production processes enable quick adaptation to new paint formulations and product lines.

Energy-Intensive Processes and Cost Pressures:

Intelligent energy management and predictive maintenance optimize resource utilization, reducing operational costs.

Stringent Environmental Regulations and Sustainability Demands:

MaintWiz ensures compliance with VOC regulations and supports eco-friendly initiatives through efficient resource utilization and waste reduction.

Quality Consistency Across Diverse Product Portfolio:

Advanced analytics and real-time monitoring ensure uniform quality standards across various paint and coating types.

Skilled Labor Shortages and Knowledge Retention:

MaintWiz's intuitive interface and knowledge management features preserve expertise and streamline training for new personnel.

Streamlined Implementation for Rapid ROI in Paint Manufacturing

Experience a smooth transition to MaintWiz AI CMMS, tailored to the unique needs of your

paint and coatings production facility.

Customized Onboarding for Paint Industry Specifics:

Our experts configure MaintWiz to align with your unique paint formulation and production processes, ensuring maximum relevance and adoption.

Phased Roll-out Minimizing Production Disruptions:

Implement MaintWiz gradually across different production lines or facilities, allowing for seamless integration without impacting ongoing operations.

Comprehensive Training for Rapid User Adoption:

Tailored training programs for various user roles ensure quick proficiency and maximize the value derived from MaintWiz's advanced features.

Data Migration and System Integration:

Seamlessly transfer historical maintenance and production data, integrating MaintWiz with existing paint manufacturing systems for a unified operational view.

Continuous Support and Performance Optimization:

Our dedicated support team provides ongoing assistance, ensuring MaintWiz evolves with your paint production needs and industry trends.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.