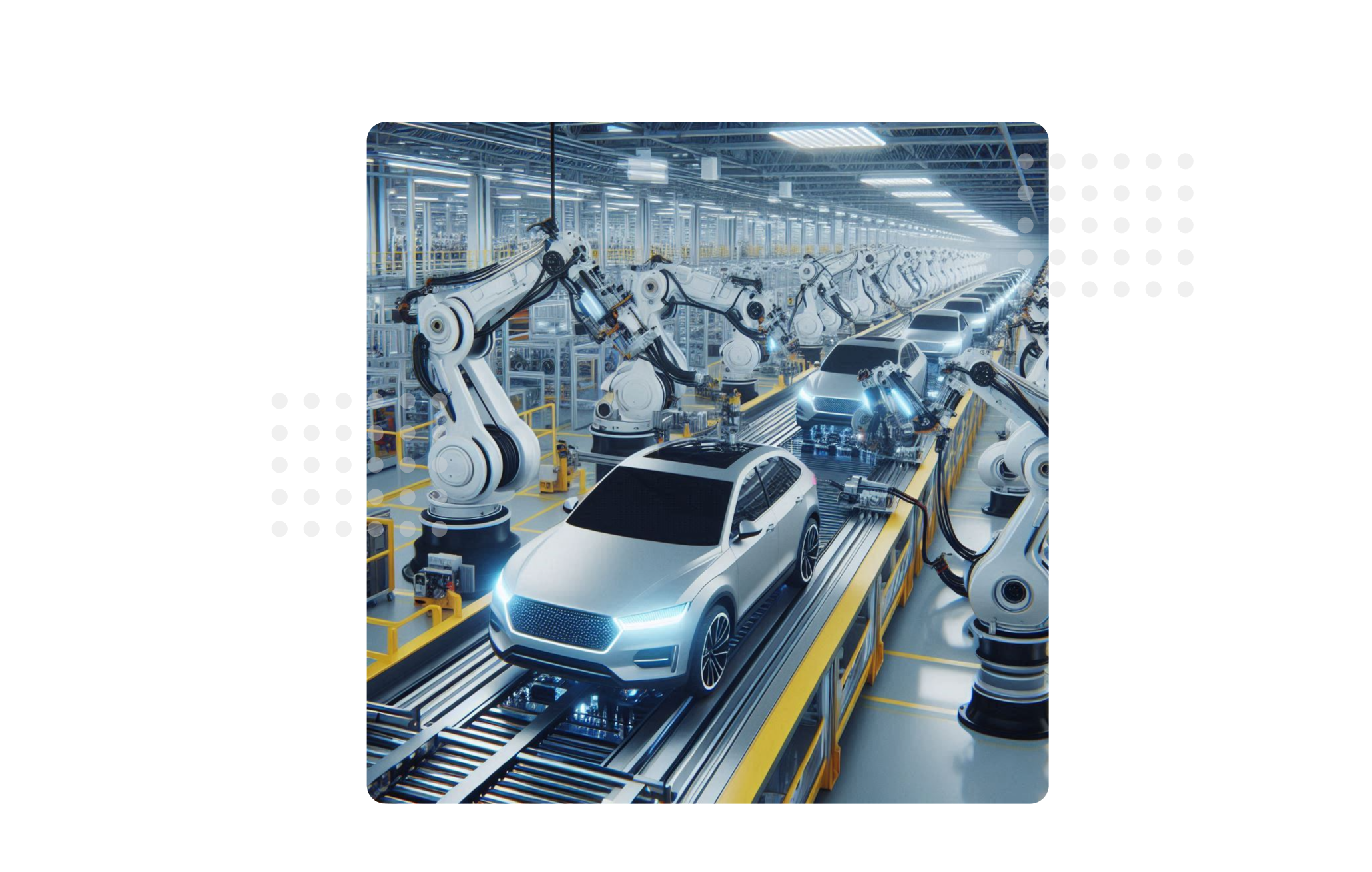

Revolutionize Automotive Maintenance with MaintWiz AI CMMS

Accelerate production, minimize downtime, and optimize asset performance with our cutting-edge AI-powered CMMS solution tailored for the automotive industry. Experience unparalleled efficiency and cost savings across your entire manufacturing ecosystem.

Transformative Benefits of MaintWiz AI CMMS for Automotive & Auto-Components

Maximize Operational Efficiency and Productivity

Streamline maintenance processes and boost overall equipment effectiveness (OEE) to meet demanding production schedules.

Predictive Maintenance for Critical Assets:

Leverage AI-driven insights to forecast equipment failures and schedule proactive maintenance, reducing unexpected downtime.

Real-time Performance Monitoring:

Track key performance indicators (KPIs) across your production line, enabling swift decision-making and continuous improvement.

Automated Work Order Management:

Streamline maintenance workflows with intelligent work order creation, prioritization, and resource allocation for maximum efficiency.

Digital Twin Integration:

Create virtual replicas of physical assets to simulate performance, optimize maintenance strategies, and enhance overall plant efficiency.

Ensure Compliance and Quality Standards

Maintain rigorous quality control and meet stringent industry regulations with our comprehensive compliance management features.

Automated Compliance Reporting:

Generate detailed reports for ISO 9001, IATF 16949, and other automotive standards, simplifying audits and ensuring regulatory adherence.

Quality Control Integration:

Seamlessly incorporate quality checks into maintenance processes, ensuring consistent product excellence and minimizing defects.

Environmental Compliance Tracking:

Monitor and manage environmental impact metrics, supporting sustainability initiatives and compliance with ISO 14001 standards.

Safety Protocol Enforcement:

Implement and track safety procedures, reducing workplace incidents and ensuring compliance with OSHA and industry-specific regulations.

Top Companies in India & Abroad Trust MaintWiz CMMS

Optimize Supply Chain and Inventory Management

Enhance your supply chain efficiency and reduce inventory costs with intelligent spare parts management and vendor integration.

Just-in-Time Inventory Optimization:

Utilize AI-powered demand forecasting to maintain optimal inventory levels, reducing carrying costs without compromising maintenance efficiency.

Supplier Performance Tracking:

Monitor and evaluate vendor reliability, quality, and delivery times to ensure a robust and efficient supply chain.

Automated Reordering System:

Implement smart reordering processes that trigger purchase requests based on usage patterns and criticality of spare parts.

Multi-site Inventory Visibility:

Gain real-time insights into inventory levels across multiple facilities, enabling efficient resource allocation and cost reduction.

Enhance Asset Lifecycle Management

Maximize the lifespan and performance of your automotive manufacturing assets with comprehensive lifecycle management tools.

Condition-based Maintenance Strategies:

Implement sophisticated maintenance regimes based on real-time asset condition data, optimizing performance and longevity.

Asset Performance Analytics:

Leverage advanced analytics to identify underperforming assets, guide replacement decisions, and optimize capital expenditure planning.

Energy Efficiency Monitoring:

Track and analyze energy consumption patterns to identify opportunities for improved efficiency and reduced operational costs.

Warranty and Service Contract Management:

Streamline warranty claim processes and track service contracts to maximize cost recovery and minimize maintenance expenses.

Speak to a Specialist

Get personalised advice from our experts

Drive Industry 4.0 Initiatives

Accelerate your digital transformation journey with MaintWiz AI CMMS's advanced Industry 4.0 capabilities.

IoT Sensor Integration:

Seamlessly connect with IoT devices to gather real-time data on asset performance, enabling proactive maintenance and improved decision-making.

AI-powered Anomaly Detection:

Utilize machine learning algorithms to identify abnormal equipment behavior, preventing potential failures and production disruptions.

Augmented Reality Maintenance Support:

Empower technicians with AR-assisted maintenance procedures, reducing repair times and improving first-time fix rates.

Blockchain-enabled Traceability:

Implement secure, transparent record-keeping for critical components and maintenance activities, enhancing accountability and compliance.

Why Choose MaintWiz AI CMMS for Automotive Excellence?

MaintWiz AI CMMS is the ultimate solution for automotive manufacturers seeking to optimize their maintenance operations and drive continuous improvement:

Comprehensive Coverage Across Your Automotive Manufacturing Facility

MaintWiz AI CMMS offers tailored solutions for every critical area of your automotive production process, ensuring seamless operations and optimal performance:

Body Shop:

- Predictive maintenance for robotic welding systems

- Real-time monitoring of press shop equipment performance

- Automated lubrication schedules for conveyor systems

- Energy consumption optimization for paint booths

Powertrain Assembly:

- Precision tracking of tooling and fixture calibrations

- AI-driven quality control integration for engine assembly

- Automated work order generation for CNC machine maintenance

- Real-time monitoring of test bench performance

Final Assembly:

- Streamlined maintenance for conveyor and material handling systems

- IoT-enabled monitoring of torque tool performance

- Automated scheduling for preventive maintenance during line changeovers

- Real-time tracking of vehicle-specific quality checks

Logistics and Warehouse:

- Optimized maintenance schedules for automated guided vehicles (AGVs)

- Predictive analytics for forklift fleet management

- IoT-enabled monitoring of storage and retrieval systems

- Real-time inventory tracking integrated with maintenance needs

Seamless Integration for Comprehensive Automotive Manufacturing Intelligence

MaintWiz AI CMMS offers a robust integration ecosystem, enabling a holistic approach to automotive manufacturing excellence:

ERP System Integration:

Seamlessly connect with SAP, Oracle, or other ERP solutions for streamlined financial planning and resource allocation across maintenance operations.

Manufacturing Execution System (MES) Connectivity:

Integrate with your MES to synchronize production schedules with maintenance activities, optimizing overall equipment effectiveness (OEE).

IoT and Sensor Data Aggregation:

Collect and analyze real-time data from connected devices across your production line for predictive maintenance and performance optimization.

Quality Management System (QMS) Alignment:

Ensure seamless communication between maintenance activities and quality control processes, maintaining high standards throughout production.

Transform Automotive Manufacturing with AI-Driven MaintWiz CMMS to Enhance Quality & Reduce Downtime

Overcoming Automotive Industry Challenges with MaintWiz AI CMMS

Address critical success factors and industry-specific challenges with our tailored CMMS solution:

Rapid Production Line Adaptability:

Quickly adjust maintenance schedules and asset configurations to accommodate frequent model changes and production line modifications.

Supply Chain Resilience & Just-in-Time Production:

Optimize inventory management and maintenance schedules to support lean manufacturing principles and minimize production disruptions.

Skilled Workforce Retention and Knowledge Transfer:

Capture and preserve critical maintenance knowledge through digital workflows and AI-assisted training modules for new technicians.

Stringent Quality and Safety Compliance:

Maintain rigorous quality standards & safety protocols through automated checks, documentation, reporting aligned with industry regulations.

Energy Efficiency and Sustainability Initiatives:

Monitor and optimize energy consumption across your facility, supporting green manufacturing goals and reducing operational costs.

Continuous Improvement and Lean Manufacturing:

Leverage advanced analytics and real-time KPI tracking to identify improvement opportunities and drive operational excellence.

Streamlined Implementation for Rapid ROI in Automotive Manufacturing

Experience a smooth transition to MaintWiz AI CMMS with our proven implementation process:

Customized Needs Assessment and Planning:

Collaborate with our industry experts to tailor MaintWiz to your specific automotive manufacturing requirements and integration needs.

Phased Roll-out and Change Management:

Implement MaintWiz gradually across your facility, ensuring minimal disruption to ongoing operations and maximizing user adoption.

Comprehensive Training and Support:

Benefit from hands-on training sessions and ongoing support to ensure your team leverages MaintWiz's full potential from day one.

Continuous Optimization and ROI Tracking:

Monitor key performance indicators and work closely with our team to continuously refine and optimize your MaintWiz implementation.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.