Transform Manufacturing Excellence with MaintWiz Early Equipment Management

Revolutionize your equipment lifecycle management with AI-powered TPM solutions. Reduce maintenance costs by 40%, extend asset life, and maximize ROI from day one.

Elevate Equipment Performance Through Smart Design Integration

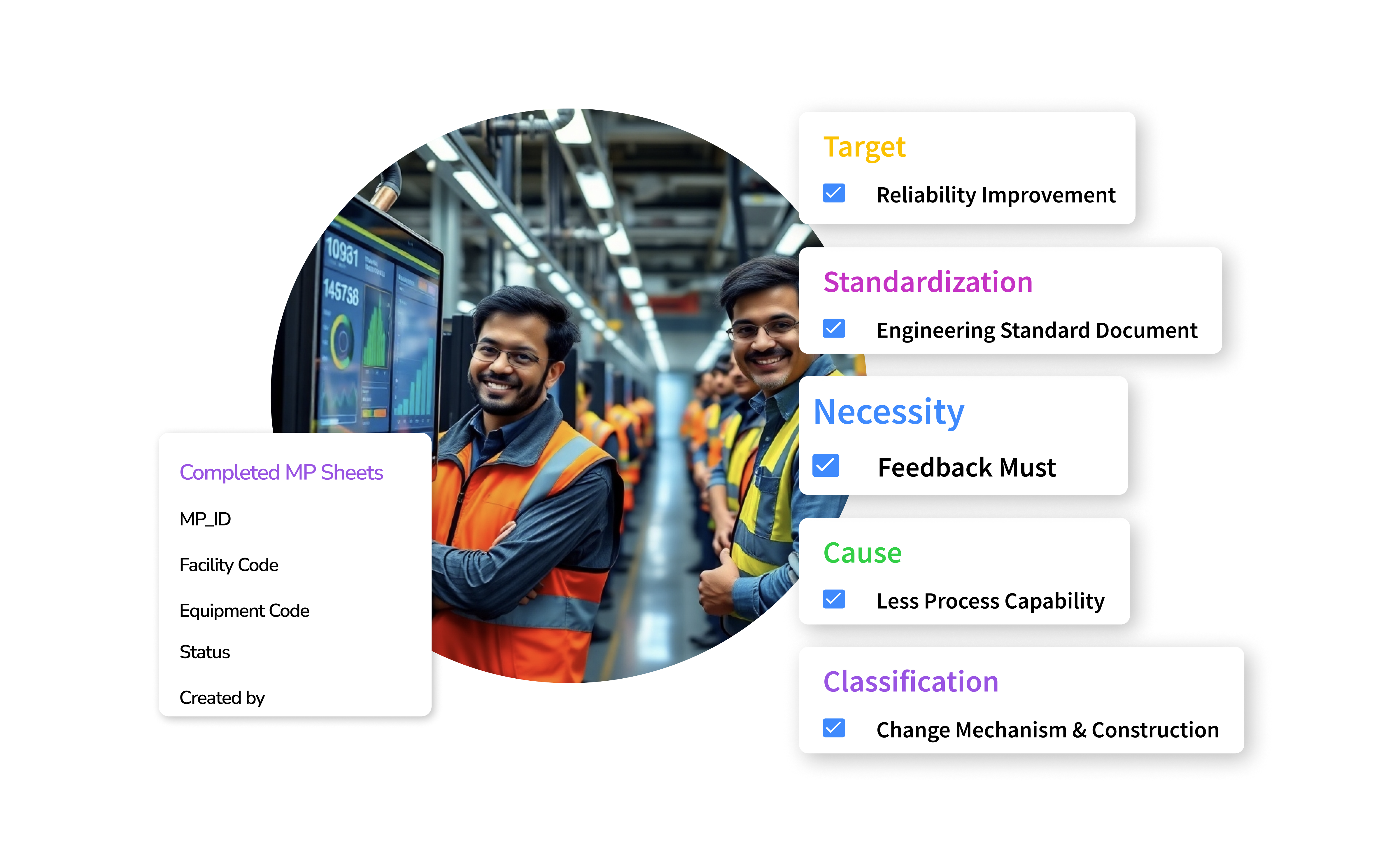

Empower your engineering teams with data-driven insights that transform equipment reliability and maintenance efficiency from the design phase.

Forge Powerful Engineering-Maintenance Collaboration Platforms

MaintWiz’s collaborative workspace bridges the gap between design and maintenance teams, enabling real-time knowledge sharing and joint decision-making that reduces equipment lifecycle costs by up to 35% while boosting reliability metrics significantly.

Leverage Historical Performance Data for Design Excellence

Transform years of maintenance data into actionable design insights. Our AI-powered analytics engine identifies critical failure patterns and optimization opportunities, helping you create equipment specifications that minimize downtime and maintenance needs.

Optimize Component Accessibility for Rapid Maintenance

Visual planning tools enable strategic placement of high-wear components, reducing mean time to repair by 60%. Smart access point design and modular architectures dramatically reduce maintenance labor hours while improving safety metrics.

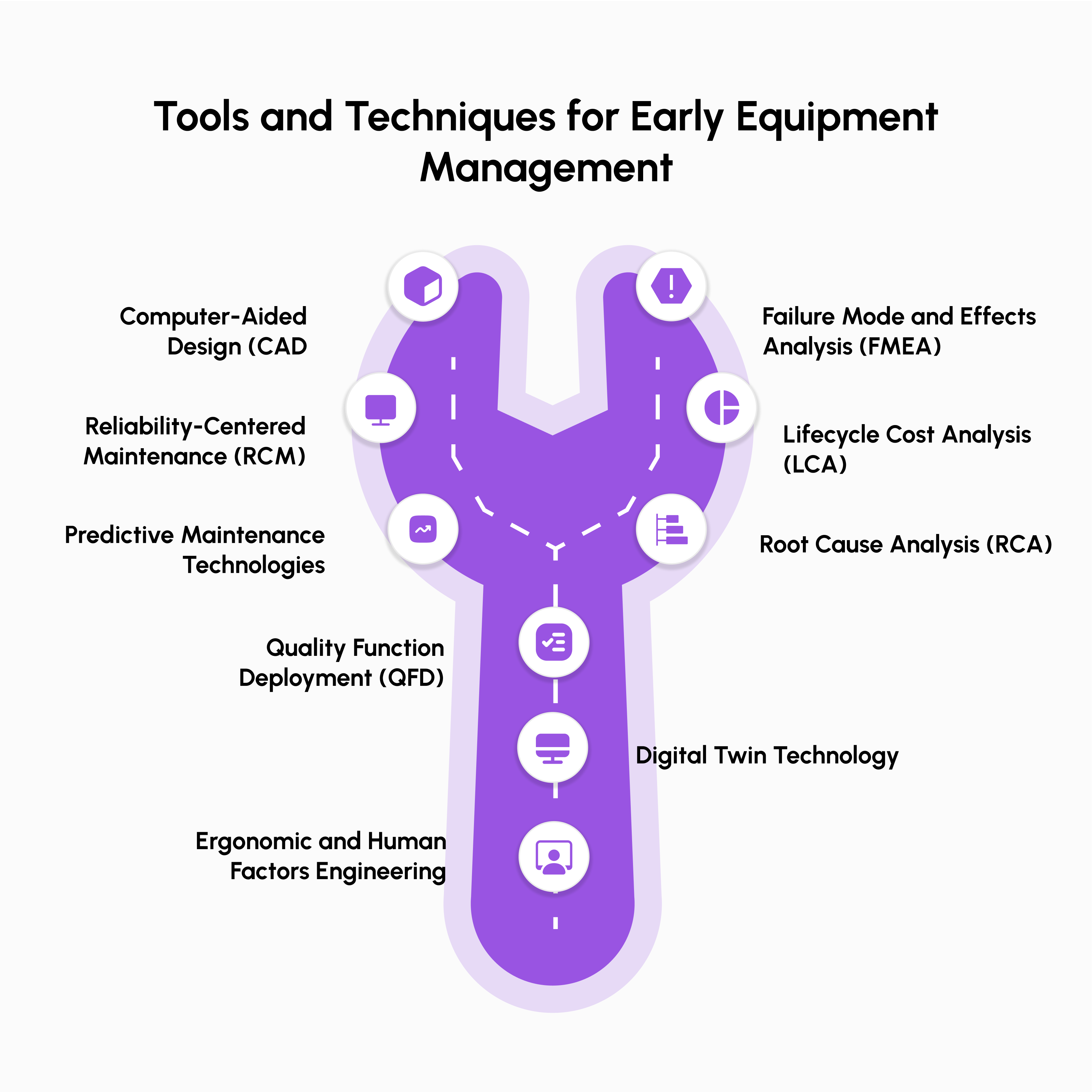

Design for Reliability with MaintWiz's Comprehensive Toolkit

Embed reliability into every design decision using MaintWiz’s comprehensive reliability analysis toolkit. Balance performance requirements with maintenance considerations to create equipment that delivers consistent uptime and reduced maintenance costs.

Reduce Failures with MaintWiz's Intelligent Safeguard Mechanisms

Design robust fail-safe systems using MaintWiz’s risk assessment module. Our platform helps identify critical failure modes and implements appropriate safeguards, reducing catastrophic failures by 75% while protecting valuable assets.

Ergonomic Interfaces for Enhanced Operation for Efficiency and Safety

Optimize human-machine interfaces using advanced ergonomic design principles. MaintWiz’s interface planning tools reduce operator errors by 40% while improving maintenance efficiency and workplace safety standards.

Accelerate Equipment Excellence Through Seamless Commissioning

Transform your equipment deployment process with intelligent commissioning tools that ensure peak performance from day one.

Master the Installation-to-Operation Transition

Streamline equipment deployment using MaintWiz’s digital commissioning workflows. Our structured approach reduces setup time by 45% while ensuring every critical parameter is verified and optimized for peak performance.

Minimize Production Impact During Equipment Setup

Orchestrate seamless equipment integration using our advanced planning tools. Smart scheduling algorithms and resource optimization features reduce commissioning downtime by 50% while maintaining production targets.

Achieve Day-One Performance Excellence

Deploy equipment at peak efficiency using MaintWiz’s performance optimization module. Real-time monitoring and adjustment tools ensure new installations meet or exceed OEM specifications from the first production run.

Deliver Comprehensive Operator Training Programs

Transform operator capabilities through MaintWiz’s multimedia training platform. Interactive modules and hands-on simulations reduce learning curves by 60% while ensuring consistent equipment operation across shifts.

Capture Critical Early-Stage Performance Data

Monitor and analyze equipment behavior during crucial early operations. Our advanced analytics identify optimization opportunities and potential issues before they impact production, ensuring stable long-term performance.

Implement Lean Equipment Launch Strategies

Execute efficient equipment launches using proven lean methodologies. MaintWiz’s structured approach eliminates waste, reduces setup time, and achieves stable operations faster through systematic optimization.

Speak to a Specialist

Get personalised advice from our experts

Maximize ROI Through Strategic Lifecycle Cost Management

Transform equipment economics with intelligent lifecycle cost analysis and optimization strategies.

Balance Investment Decisions with Lifetime Value

Make informed capital decisions using MaintWiz’s comprehensive lifecycle cost calculator. Our platform analyzes initial investments against long-term operational costs, helping you optimize equipment ROI across its entire lifespan.

Forecast Maintenance and Energy Expenditure

Predict and optimize future costs using advanced forecasting models. MaintWiz’s predictive analytics help you plan maintenance budgets more accurately while identifying opportunities for energy efficiency improvements.

Drive Long-term Operational Excellence

Optimize equipment performance through intelligent operation strategies. Our platform identifies efficiency opportunities that reduce operational costs by 30% while extending equipment life significantly.

Select Premium Components for Lasting Value

Make strategic component choices using MaintWiz’s material performance database. Compare lifecycle costs against reliability metrics to select components that deliver optimal long-term value and performance.

Eliminate Hidden Operational Costs

Uncover and address hidden cost drivers using comprehensive cost analysis tools. Our platform helps identify and eliminate inefficiencies that impact your bottom line while optimizing resource utilization.

Implement Sustainable Management Practices

Drive environmental and economic sustainability through intelligent asset management. MaintWiz helps reduce energy consumption and waste while maximizing equipment efficiency and longevity.

Transform Equipment Intelligence with Predictive Capabilities

Elevate equipment performance through advanced predictive technologies and real-time monitoring solutions.

Integrate IoT Solutions for Real-time Monitoring

Connect your equipment to MaintWiz’s IoT platform for continuous health monitoring. Our system processes real-time data from multiple sensors to provide instant insights into equipment performance and condition.

Enable Predictive Maintenance from Design Phase

Build predictive capabilities into new equipment using MaintWiz’s design integration tools. Our platform helps identify optimal sensor placement and monitoring points for effective condition-based maintenance.

Minimize Failure Risk Through Data Analytics

Prevent equipment failures using advanced pattern recognition algorithms. MaintWiz’s predictive analytics identify potential issues weeks in advance, allowing proactive intervention before failures occur.

Drive Equipment Evolution Through Intelligence

Continuously improve equipment design using operational insights. Our platform analyzes performance data to recommend design modifications that enhance reliability and reduce maintenance needs.

Deploy Smart Diagnostic Solutions

Accelerate troubleshooting with intelligent diagnostic tools. MaintWiz’s expert system guides maintenance teams through efficient problem resolution, reducing diagnostic time by 55%.

Implement Early Warning Systems

Detect potential issues before they impact production. Our advanced monitoring system provides early warnings of developing problems, enabling proactive maintenance intervention.

Voices of Our Valued Clients

With MaintWiz, Early Equipment Management has transformed our approach to equipment reliability.

Early Equipment Management through MaintWiz has helped us predict issues before they impact operations.

MaintWiz enables us to identify potential failures early, improving overall equipment reliability

Using MaintWiz’s EEM functionality, we can address issues before they become costly breakdowns.

Early Equipment Management with MaintWiz ensures our machines are always in top condition.

MaintWiz’s proactive approach through EEM reduces downtime and boosts production efficiency

EEM practices through MaintWiz help us avoid costly failures and enhance operational longevity

MaintWiz has streamlined our Early Equipment Management, leading to fewer breakdowns and smoother operations.

Optimize Operations Through Data-Driven Decision Making

Transform equipment management with powerful analytics and intelligent decision support tools.

Harness Historical Data for Equipment Enhancement

Convert maintenance history into actionable insights. MaintWiz’s analytics engine processes years of operational data to identify patterns and opportunities for equipment optimization.

Drive Improvements Through Predictive Analytics

Make informed decisions using advanced predictive models. Our platform analyzes multiple data streams to forecast equipment behavior and recommend optimal maintenance strategies.

Enhance Equipment Reliability Through Analytics

Boost equipment performance using data-driven insights. MaintWiz’s reliability analysis tools help identify and address factors affecting equipment dependability and efficiency.

Optimize Lifecycle Costs Using Intelligence

Reduce total cost of ownership through smart decision making. Our platform provides comprehensive cost analysis and optimization recommendations based on real operational data.

Align Operations with Kaizen Objectives

Drive continuous improvement using structured data analysis. MaintWiz helps identify and implement incremental improvements that align with your organization’s Kaizen goals.

Enable Smart Resource Allocation

Optimize maintenance resources using intelligent planning tools. Our platform analyzes workload patterns and equipment needs to recommend optimal resource deployment strategies.

Preserve Excellence Through Strategic Knowledge Management

Build a sustainable knowledge foundation that drives continuous improvement in equipment management.

Document Critical Installation Learnings

Track equipment condition through comprehensive monitoring tools. Digital sensors and inspection records provide detailed insights into wear patterns, enabling proactive maintenance interventions.

Standardize Project Management Excellence

Capture and preserve valuable implementation insights. MaintWiz’s knowledge management system ensures critical lessons from each installation are documented and easily accessible for future reference.

Accelerate Future Implementations

Speed up equipment deployment using proven methodologies. MaintWiz’s reference library provides quick access to successful installation procedures and best practices from previous projects.

Build Comprehensive TPM Knowledge Base

Develop a centralized repository of TPM expertise. Our platform organizes and preserves critical knowledge, making it easily accessible to teams across your organization.

Enable Effective Knowledge Transfer

Facilitate seamless information sharing between teams. MaintWiz’s collaboration tools ensure critical knowledge flows efficiently across departments and locations.

Maintain Historical Performance Records

Track and analyze long-term equipment performance. Our system maintains detailed historical records that help refine future EEM strategies and improve equipment reliability.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.