Transform Asset Performance with MaintWiz Digital Twin Technology

Revolutionize your industrial operations with next-generation digital twin technology that delivers unprecedented asset visibility, predictive insights, and operational excellence while maximizing return on investment.

Accelerate Digital Transformation Through Intelligent Asset Management

Step into the future of industrial asset management with MaintWiz's revolutionary digital twin platform. By creating precise virtual replicas of your physical assets, our solution enables real-time monitoring, predictive maintenance, and data-driven optimization. Transform your maintenance strategy from reactive to predictive while achieving operational excellence across your enterprise. Our comprehensive platform integrates seamlessly with existing systems, providing immediate value and scalable growth potential.

Master Asset Performance Through Digital

Replication Excellence

Unlock unprecedented visibility and control over your industrial operations with perfect digital replicas of mission-critical assets, enabling real-time monitoring and optimization at enterprise scale.

Enterprise-Grade Asset Virtualization Platform

Transform complex physical assets into intelligent digital models with our advanced virtualization engine, enabling comprehensive monitoring and dynamic performance optimization across your entire industrial infrastructure.

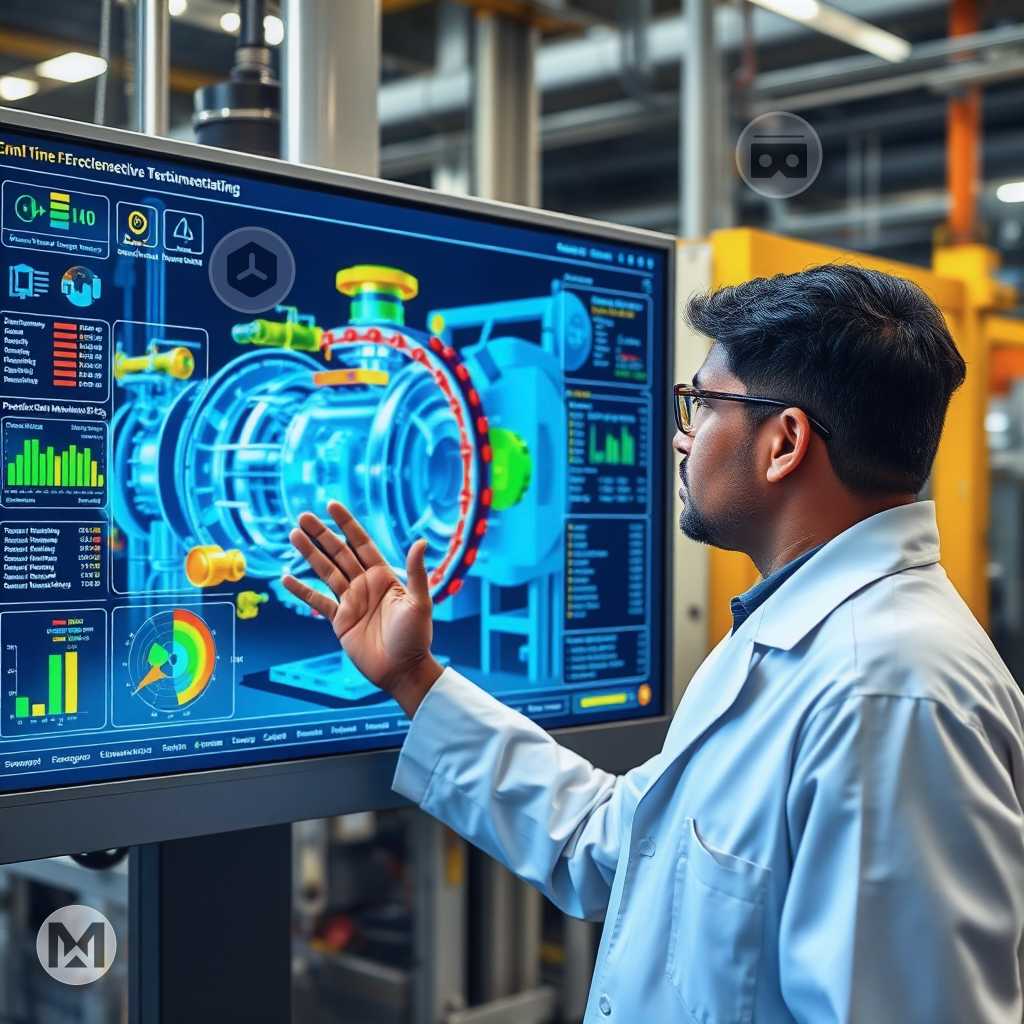

Real-Time Performance Analytics Dashboard

Access sophisticated operational insights through intuitive dashboards that convert complex asset data streams into actionable intelligence, empowering strategic decision-making and immediate response capabilities.

Unified Team Collaboration Environment

Eliminate operational silos with our integrated collaboration platform, enabling seamless information sharing and coordinated action across maintenance teams, operations personnel, and executive management.

Intelligent Performance Monitoring System

Maintain peak operational efficiency with real-time monitoring that instantly alerts stakeholders to performance deviations, enabling proactive interventions before issues impact production.

Advanced Trend Analysis Engine

Leverage sophisticated pattern recognition capabilities to identify operational trends, optimize asset performance, and drive strategic decisions based on comprehensive historical performance data.

Continuous Asset Health Assessment

Deploy our innovative health scoring system that dynamically evaluates asset condition, enabling targeted maintenance interventions and optimal resource allocation across your facility.

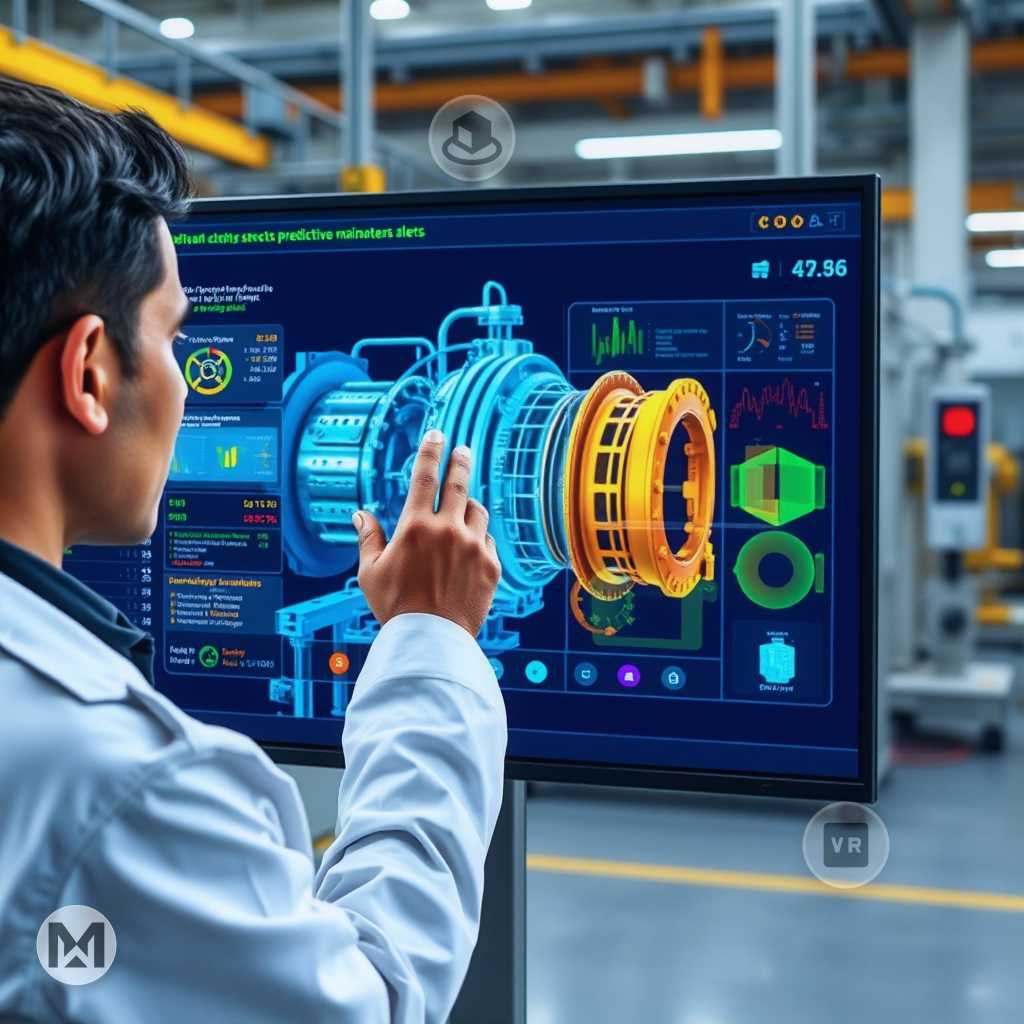

Revolutionize Maintenance Strategy with Predictive Intelligence

Transform maintenance operations through advanced AI algorithms that precisely forecast potential issues, enabling proactive interventions that prevent costly downtime.

Next-Generation Maintenance Forecasting

Utilize sophisticated machine learning algorithms that analyze multiple data streams to predict maintenance requirements with unprecedented accuracy, optimizing resource allocation and minimizing unexpected downtime.

Intelligent Condition Monitoring Platform

Deploy advanced sensor networks and monitoring systems that continuously evaluate asset health, automatically triggering maintenance alerts based on real-time performance metrics and historical patterns.

Advanced Predictive Analytics Engine

Leverage cutting-edge analytics to identify subtle performance anomalies and emerging maintenance needs, enabling timely interventions that prevent equipment failures and production disruptions.

Enterprise IoT Integration Framework

Seamlessly consolidate data from diverse IoT sensors to create comprehensive asset health profiles, enabling more accurate predictions and strategically informed maintenance decisions.

Adaptive Machine Learning Suite

Enhance maintenance predictions through self-optimizing algorithms that continuously learn from your specific operational patterns and equipment characteristics, improving accuracy over time.

Smart Maintenance Scheduling System

Generate optimal maintenance schedules automatically based on real-time condition data, resource availability, and production demands, maximizing equipment uptime and operational efficiency.

Speak to a Specialist

Get personalised advice from our experts

Optimize Asset Lifecycle Through Data-Driven Intelligence

Maximize asset longevity and performance through comprehensive lifecycle management powered by advanced analytics and real-time operational insights.

Centralized Asset Intelligence Repository

Consolidate critical asset information in a secure, accessible platform that enables informed decision-making through comprehensive data integration and advanced analytics capabilities.

Advanced Wear Pattern Analysis

Leverage sophisticated algorithms to analyze equipment degradation patterns, enabling optimized maintenance scheduling and more accurate lifecycle cost predictions for critical assets.

Strategic Replacement Planning Engine

Generate data-driven recommendations for asset replacement timing, balancing maintenance costs, performance requirements, and capital expenditure optimization across your facility.

Comprehensive Trend Intelligence System

Analyze historical performance data to identify patterns and trends, enabling proactive maintenance strategies that extend asset life and optimize operational efficiency.

Cost Optimization Analytics Suite

Deploy advanced financial modeling tools that analyze lifecycle costs, maintenance expenses, and replacement timing to optimize capital expenditure and maximize return on investment.

Performance Enhancement Framework

Implement continuous improvement strategies based on real-time performance data, extending asset longevity while maintaining peak operational efficiency across your enterprise.

Accelerate Digital Evolution with Industry 4.0 Integration

Seamlessly connect your industrial assets with cutting-edge Industry 4.0 technologies, enabling enhanced operational intelligence and cross-functional optimization.

Advanced Technology Integration Platform

Synchronize operations with state-of-the-art IoT sensors, AI algorithms, and machine learning capabilities, creating a comprehensive digital ecosystem that drives operational excellence.

Enterprise System Interoperability Framework

Enable seamless communication between existing industrial systems and advanced digital technologies, creating a unified operational environment that enhances efficiency and decision-making.

Cross-Platform Data Exchange Network

Facilitate efficient information flow across diverse industrial platforms and departments, enabling real-time collaboration and improved operational visibility throughout your organization.

Secure Industrial Network Architecture

Implement enterprise-grade security protocols that protect sensitive operational data while enabling authorized access across your industrial network infrastructure.

Intelligent Decision Support System

Leverage advanced analytics and machine learning to provide actionable insights, enabling informed decision-making across all levels of your organization.

Digital Transformation Acceleration Suite

Fast-track your Industry 4.0 journey with integrated tools and technologies that enhance operational efficiency, reduce costs, and drive continuous improvement initiatives.

Drive Excellence Through Digital Process Simulation

Optimize operations and minimize risks through advanced simulation capabilities that enable virtual testing and validation of process improvements.

Advanced Process Simulation Engine

Test and validate operational changes in a risk-free virtual environment, enabling confident implementation of process improvements while minimizing potential disruptions to production.

Virtual Process Optimization Platform

Evaluate multiple improvement scenarios simultaneously, identifying optimal solutions that maximize efficiency and productivity while minimizing operational risks and resource requirements.

Risk Mitigation Modeling System

Analyze potential operational risks through sophisticated modeling capabilities, enabling proactive risk management and enhanced decision-making across your industrial processes.

Adaptive Operations Framework

Respond rapidly to changing operational conditions through dynamic simulation capabilities that enable quick assessment and implementation of process adjustments.

Resource Optimization Engine

Maximize operational efficiency through virtual testing of resource allocation strategies, enabling optimal utilization of assets, personnel, and materials across your facility.

Sustainability Implementation Platform

Support environmental initiatives through simulation-based optimization of energy consumption, waste reduction, and resource utilization, advancing your sustainability objectives.

Maximize Asset Intelligence Through IoT Connectivity

Harness the power of connected assets to revolutionize your maintenance strategy with real-time monitoring and intelligent insights.

Advanced Real-Time Asset Health Monitoring System

Transform maintenance decisions with continuous performance tracking & instant health status updates, enabling proactive intervention before issues escalate into costly downtime scenarios.

Enterprise-Wide IoT Integration Framework

Unite all asset data streams into a centralized platform, creating a comprehensive single source of truth that drives informed decision-making and strategic maintenance planning.

Comprehensive Asset Visibility Network

Implement wireless sensor networks that provide unprecedented visibility into asset performance, enabling real-time monitoring & control across your entire facility.

Environmental Performance Optimization Suite

Monitor critical environmental parameters & operational metrics through advanced sensor integration, ensuring optimal asset performance & compliance with industry standards.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.