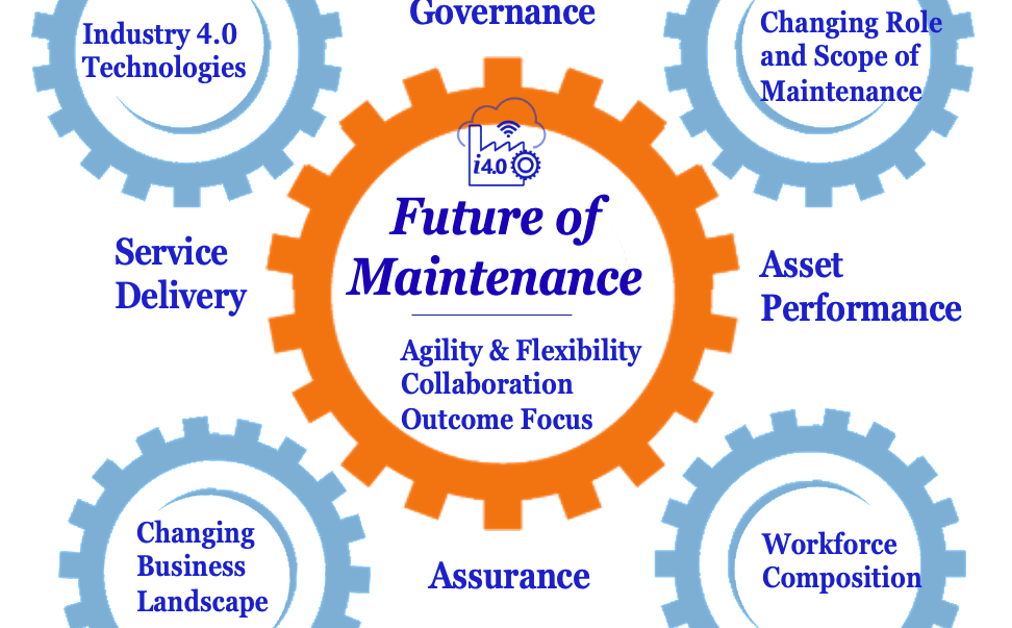

Automation and other advances in manufacturing technology have resulted in large sophisticated production systems that can seldom fail. Yet the diverse environmental factors and operating conditions make them susceptible and vulnerable to failures. Enterprise maintenance strategy needs to constantly adapt to meet the challenges posed by the changing technology and evolving corporate goals of a competitive business environment.

Maintenance Strategy is the set of administrative, technical and managerial actions that are applied during the life cycle of an asset, to meet the business goals of maximizing asset performance and asset life. It encompasses the policies and procedures, processes and frameworks, governance, supervisory and operational controls implemented across the enterprise to support the stated business goals.

Table of Contents

Definition of a holistic maintenance strategy needs to address the following six critical elements.

Availability:

Availability defines the degree to which the equipment is up, operable and ready for use. It is generally measured as the ratio of the uptime to the total time and expressed in percentage. Any planned maintenance time is excluded from the denominator.

Reliability:

Reliability is the ability of an equipment to perform without any failure under stated conditions and for a stated period of time. It’s measured by the probability of success. Recurrence and frequency of failures influence the probability and thus impair reliability. Reliability is often ensured with full redundancy of critical systems and where possible distributed geographically.

- Availability and reliability are often confused. Availability is a measure of the percentage of time the equipment is up and operational whereas reliability is a measure of the probability of success. In conventional industries like manufacturing where overall uptime is more important and a small failure is acceptable, availability scores over reliability. In mission-critical industries like aircraft and nuclear energy, the risk of failure is catastrophic and reliability is used as the prime indicator.

Maintainability:

While maintainability is crucial for ensuring the longevity and reliability of equipment, it can be challenging to maintain assets without proper monitoring. That’s where condition monitoring comes in. By implementing a condition monitoring system, businesses can continuously track the health of their assets and detect potential issues before they escalate. Condition-based monitoring utilizes data from sensors and other sources to provide real-time insights into asset performance, enabling businesses to optimize maintenance strategies and minimize downtime. MTBF and MTTR metrics can also be used to assess the effectiveness of the condition monitoring system and identify areas for improvement.

Safety:

Safety pertains to managing all plant operations in such a way as to minimize hazards, risks, accidents and near misses, thereby protecting the people, assets, and environment from getting harm or danger from random events.

Security:

Security is the state of being free from danger or threat, especially from deliberately planned activities designed to cause harm or danger.

- Safety and security are closely related and thus often jumbled. Safety is protection against random or chance events that may result in personal injury or impact assets and environment negatively. Security is protection against intended or deliberate incidents, perpetrated to cause harm or danger to people, assets, environment or business.

Sustainability:

Sustainability is the endurance of systems and processes to withstand the challenges arising over time and staying relevant. Sustainability is often a balancing act of meeting today’s needs without compromising the well-being of future generations. Thus sustainability often extends beyond the boundaries of business to include environmental protection and corporate social responsibility.

Higher availability, reliability, maintainability, safety, and security of industrial plants should remain the paramount goals of any maintenance strategy. Sustainability ensures a responsible growth and asset management. Achieving these goals guarantees continuous non-stop operations, fewer failures, extended asset life, better operational efficiency, safe and secure conditions for people, assets, and environment.

MaintWiz CMMS helps in implementing the maintenance strategy via systematic breakdown response, well-defined preventive-maintenance-schedules, intelligent machine integration for predictive maintenance and outcome drove analytics, to accomplish all the goals for the six key elements.

MaintWiz industry 4.0 is a Simple, Easy to use, Integrated, Cost effective and Scalable solution. It’s offered as a Software-as-a-Service, with one click maintenance enabled through the native Mobile App.