Transform Manufacturing Quality with Advanced TPM-driven Maintenance Solutions

Revolutionize your quality maintenance processes with MaintWiz's comprehensive TPM solution. Drive operational excellence through integrated quality-focused maintenance strategies that deliver zero defects and enhanced product quality.

Achieve Zero-Defect Manufacturing Through Quality-Focused Maintenance

Elevate your maintenance operations with quality-centric protocols that ensure manufacturing excellence. MaintWiz's intelligent CMMS platform seamlessly integrates quality maintenance principles into daily operations.

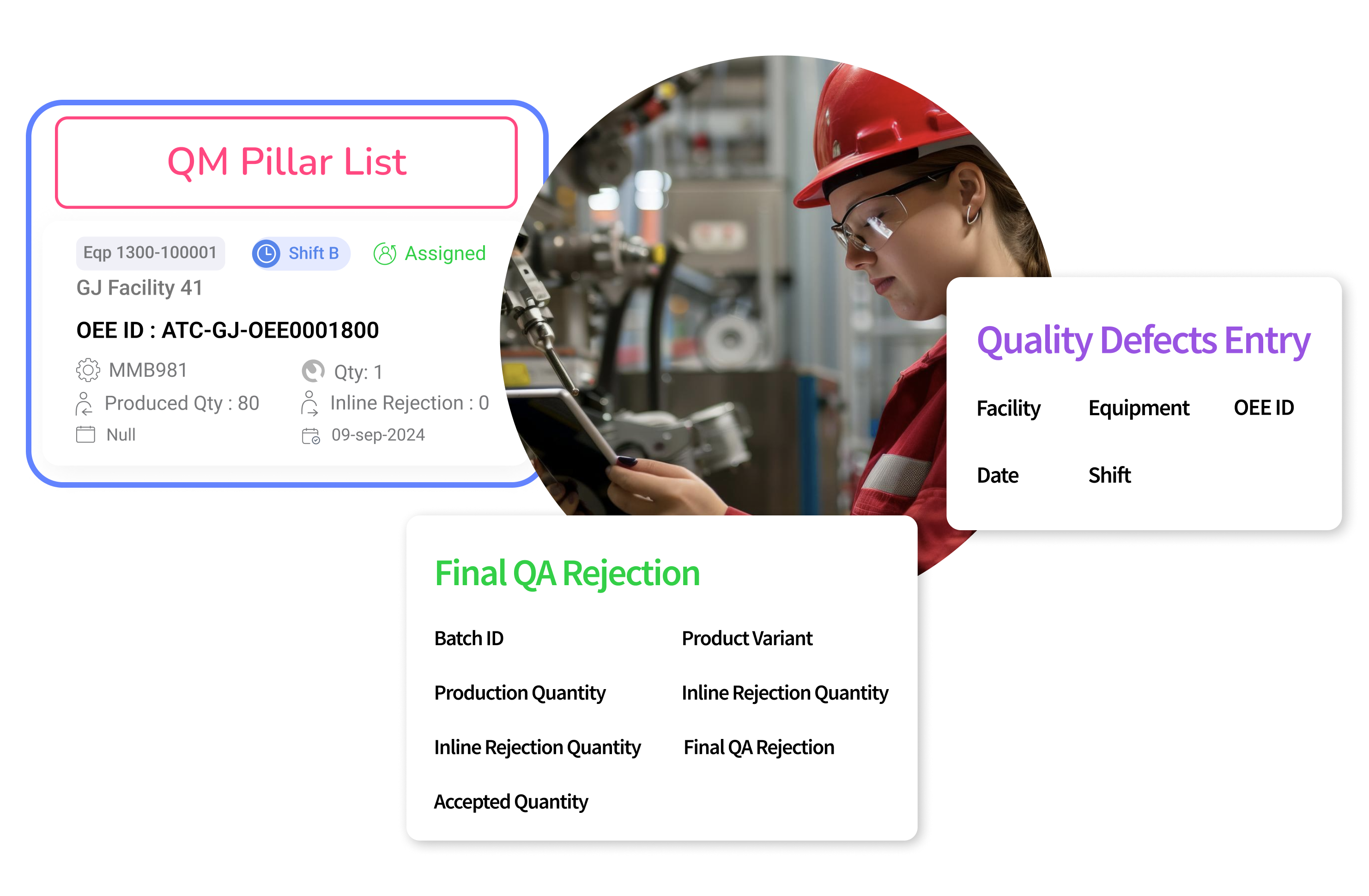

Automated Quality Inspection Workflows Reduce Defect Rates by 45%

Deploy intelligent quality inspection routines that automatically trigger maintenance actions based on real-time quality metrics. Our system ensures proactive quality maintenance through dynamic checkpoints and automated alerts, reducing quality-related downtime significantly.

Real-time Quality Performance Monitoring Enhances OEE by 25%

Monitor quality metrics in real-time with advanced analytics dashboards that highlight trends and anomalies. MaintWiz’s integrated quality monitoring system helps maintain consistent product quality while reducing defect rates through predictive maintenance.

Compliance-driven Task Prioritization Ensures Quality Standards

Leverage our intelligent task prioritization engine that automatically adjusts maintenance schedules based on quality compliance requirements. This ensures critical quality parameters are maintained while optimizing resource allocation.

Dynamic Quality Checklists Standardize Inspection Processes

Implement comprehensive quality checklists that adapt based on equipment condition and production requirements. Our dynamic checklist system ensures consistent quality standards across all maintenance activities.

Quality Metric Integration Drives Maintenance Excellence

Seamlessly integrate quality metrics with maintenance KPIs to create a holistic view of equipment performance. This integration enables data-driven decisions that optimize both maintenance efficiency and product quality.

Automated Quality Audits Ensure Maintenance Compliance

Schedule and conduct automated quality audits that verify maintenance compliance with quality standards. Our system generates detailed audit reports and tracks corrective actions to closure.

Defect Elimination Through Standardized Processes

Implement robust defect tracking and elimination processes with MaintWiz's comprehensive quality management tools.

Advanced Defect Tracking System Accelerates Resolution

Track and analyze defects with our sophisticated quality incident management system. MaintWiz enables rapid defect identification, classification, and resolution tracking, reducing mean time to repair significantly.

Standardized Resolution Protocols Enhance Quality Control

Implement standardized protocols for defect resolution that ensure consistent quality outcomes. Our system guides maintenance teams through proven resolution steps while maintaining detailed documentation.

Historical Pattern Analysis Prevents Quality Issues

Utilize powerful analytics to identify patterns in historical defect data. Our predictive capabilities help prevent recurring quality issues through early warning indicators and automated preventive actions.

Cross-functional Team Collaboration Platform

Enable seamless collaboration between maintenance, production, and quality teams. Our platform facilitates real-time communication and joint problem-solving to address quality challenges effectively.

Industry Standard Compliance in Defect Management

Ensure compliance with industry standards through structured defect management workflows. MaintWiz’s system adapts to your industry’s specific quality requirements and regulatory standards.

Comprehensive Defect Resolution Documentation

Maintain detailed documentation of defect resolution processes and outcomes. Our system automatically generates comprehensive reports tracking every step from identification to resolution.

Speak to a Specialist

Get personalised advice from our experts

Root Cause Analysis for Sustained Quality Excellence

Enable data-driven decision-making with MaintWiz's sophisticated root cause analysis capabilities.

Integrated RCA Tools Drive Problem Resolution

Access built-in RCA tools including Why-Why analysis, Ishikawa diagrams, and CAPA workflows. Our structured approach ensures thorough investigation and effective resolution of quality issues.

Visual RCA Reporting Enhances Understanding

Generate clear visual representations of RCA findings and relationships. Our system creates intuitive diagrams and charts that help teams understand complex quality issues and their root causes.

Continuous Learning System Prevents Recurrence

Build a knowledge base of RCA outcomes and lessons learned. Our system helps teams apply past learnings to prevent similar quality issues from recurring.

Cross-functional RCA Team Management

Coordinate RCA teams effectively with built-in collaboration tools. Our platform enables seamless communication and document sharing among team members across departments.

Action Plan Tracking Ensures Resolution

Monitor the implementation of RCA action plans with automated tracking. Our system ensures all corrective actions are completed and verified for effectiveness.

Data-driven Decision Support for Quality

Leverage advanced analytics to support RCA-based decision-making. Our system provides data-driven insights that help teams make informed choices about quality improvements.

Continuous Quality Improvement Management

Track and optimize quality improvements with comprehensive monitoring and analysis tools.

Real-time Quality Performance Dashboards

Access intuitive dashboards displaying key quality metrics and trends. Make informed decisions with real-time quality performance data and predictive analytics.

Automated Impact Analysis of Improvements

Track the effectiveness of quality improvements automatically. Our system measures and reports the impact of each improvement initiative on overall equipment effectiveness.

Monthly Quality Review System

Conduct structured monthly quality reviews with automated reporting. Our system generates comprehensive reports highlighting key trends, achievements, and areas for improvement.

Long-term Quality Trend Analysis

Analyze long-term quality performance trends with advanced analytics. Our system helps identify patterns and opportunities for sustained quality improvement.

Quality Initiative Tracking System

Monitor and manage quality improvement initiatives effectively. Our platform provides tools to track progress, measure outcomes, and ensure successful implementation.

Continuous Feedback Loop Management

Maintain effective feedback loops between maintenance and quality teams. Our system ensures continuous communication and improvement in quality maintenance processes.

Voices of Our Valued Clients

MaintWiz’s quality maintenance tools have elevated our operations, reducing defects and downtime.

MaintWiz has integrated quality maintenance into every aspect of our operations, ensuring higher performance

Quality maintenance with MaintWiz has made a noticeable difference in our machine reliability

By maintaining quality standards, MaintWiz has improved both our equipment and product outputs

MaintWiz helps us uphold quality maintenance practices, reducing failures and increasing efficiency.

Quality maintenance with MaintWiz ensures smooth operations and minimal interruptions to production.

MaintWiz’s quality maintenance system has enhanced our production line’s efficiency and reliability

With MaintWiz, quality maintenance is a consistent focus, yielding significant results in uptime

Quality-Focused Team Development Programs

Empower your maintenance teams with comprehensive quality training and certification tools.

Structured Quality Maintenance Training

Access role-based training modules designed for quality maintenance excellence. Our integrated learning management system ensures teams stay updated with latest practices.

Quality Case Study Learning Platform

Learn from real-world quality maintenance scenarios through interactive case studies. Our platform provides practical insights and best practices from successful implementations.

Certification Management System

Track and manage team certifications with automated monitoring. Ensure your maintenance team maintains the highest standards of quality maintenance competency.

Quality Awareness Training Modules

Build a quality-conscious culture through targeted awareness programs. Our training modules help teams understand their role in maintaining quality standards.

Advanced RCA Training Program

Develop expertise in root cause analysis through specialized training. Our system provides comprehensive training in RCA techniques and tools.

Standards Compliance Training

Ensure team compliance with quality standards through targeted training. Our system provides up-to-date training on relevant quality standards and regulations.

Quality Knowledge Management Excellence

Leverage comprehensive knowledge management tools to maintain and improve quality standards.

Centralized Quality Knowledge Repository

Access a centralized database of quality maintenance procedures and best practices. Our knowledge management system ensures standardized quality maintenance across your organization.

Historical Quality Data Analytics

Analyze historical quality maintenance data for insights and trends. Our system provides powerful analytics tools to learn from past experiences and improve future performance.

Best Practices Sharing Platform

Enable effective sharing of quality maintenance best practices across teams. Our platform facilitates knowledge transfer and standardization of successful approaches.

Defect Prevention Knowledge Base

Build a comprehensive repository of defect prevention strategies. Our system helps teams learn from past experiences to prevent quality issues proactively.

Real-time Procedure Updates

Keep quality maintenance procedures current with automated version control. Ensure teams always work with the latest approved procedures and quality standards.

Quality Training Resource Center

Access comprehensive training resources for continuous quality improvement. Our platform provides structured learning materials for ongoing team development.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.