Enterprise-Grade TPM Solution for Manufacturing Excellence

Transform your maintenance strategy with MaintWiz's comprehensive TPM platform. Drive operational excellence through intelligent maintenance scheduling, real-time monitoring, and predictive analytics that reduce downtime by 37% and boost OEE by 25%

Unlock Maintenance Excellence with Smart Scheduling

Elevate your TPM implementation with AI-driven scheduling that optimizes resource allocation and maximizes equipment reliability across your enterprise.

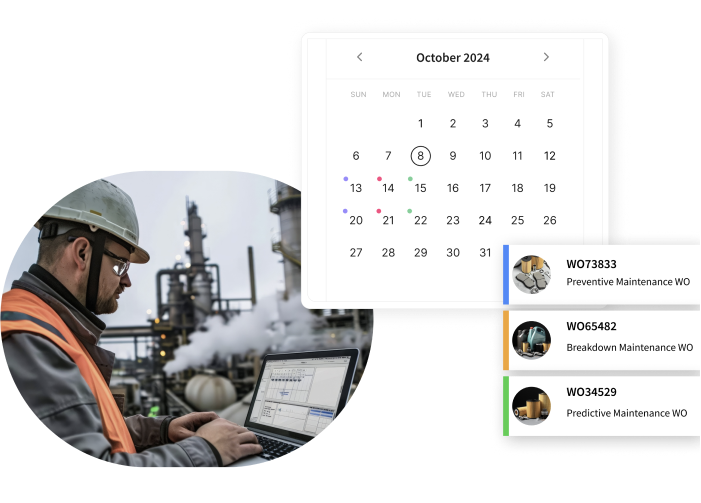

Dynamic Calendar-Based Work Order System Eliminates Planning Complexity

Transform maintenance scheduling with intelligent automation that adapts to your equipment’s unique needs. MaintWiz’s advanced algorithm analyzes historical performance data to create optimal maintenance intervals, reducing unnecessary interventions while preventing critical failures.

Condition-Based Triggers Drive Precision Maintenance

Deploy smart sensors and monitoring systems that trigger maintenance activities based on actual equipment conditions. Our integrated solution processes real-time data to initiate timely interventions, ensuring optimal equipment performance while eliminating over-maintenance.

Real-Time Asset Performance Monitoring Enables Proactive Response

Monitor critical equipment parameters continuously through our advanced IoT integration. MaintWiz’s intelligent dashboard provides instant visibility into asset health, enabling maintenance teams to address potential issues before they impact production.

Resource Planning Optimization Maximizes Workforce Efficiency

Leverage AI-powered resource allocation that matches technician skills with maintenance requirements. Our system optimizes schedules while considering work priorities, technician availability, and equipment criticality to ensure maximum maintenance effectiveness.

Predictive Analytics Integration Prevents Unexpected Downtime

Harness the power of machine learning to forecast maintenance needs with unprecedented accuracy. Our predictive engine analyzes multiple data points to identify potential failures weeks in advance, enabling truly proactive maintenance planning.

Comprehensive Downtime Analysis Guides Improvement Initiatives

Generate detailed reports that highlight opportunities for maintenance optimization. Our analytics engine identifies patterns in equipment performance, enabling targeted improvements that enhance overall equipment effectiveness.

Accelerate Breakdown Resolution with Intelligent Response Management

Minimize production disruptions through rapid response capabilities and comprehensive breakdown management tools that ensure swift resolution.

Automated Failure Detection and Notification System

Deploy instant failure alerts through our multi-channel notification system. MaintWiz automatically detects equipment failures and triggers notifications to relevant stakeholders, ensuring immediate response to critical situations.

Digital Fault Library Streamlines Troubleshooting Process

Access comprehensive troubleshooting guides and repair procedures through our digital knowledge base. Our system provides step-by-step resolution guidance, reducing diagnostic time and standardizing repair processes across your organization.

Systematic Root Cause Analysis Workflow Implementation

Execute thorough RCA investigations using our structured analysis framework. MaintWiz guides teams through systematic problem-solving, ensuring comprehensive documentation and effective countermeasures for lasting solutions.

Advanced Breakdown Pattern Recognition and Analysis

Identify recurring failure patterns through sophisticated analytics tools. Our system tracks breakdown frequencies, impact assessments, and repair histories to highlight chronic issues requiring strategic intervention.

Real-Time Status Tracking with Automated Notifications

Maintain complete visibility of breakdown resolution progress through automated status updates. Our system ensures seamless communication between maintenance teams while creating comprehensive audit trails for compliance.

Mobile-First Interface for Rapid Response Execution

Enable maintenance teams with instant mobile access to critical information and workflows. Our responsive platform ensures quick access to equipment histories, repair procedures, and real-time collaboration tools.

Speak to a Specialist

Get personalised advice from our experts

Leverage Predictive Insights for Maintenance Excellence

Transform maintenance operations with advanced analytics and machine learning that predict failures before they occur.

Historical Data Analysis Drives Predictive Maintenance

Utilize sophisticated algorithms that analyze maintenance histories to forecast potential failures. Our system learns from past performance patterns to predict equipment behavior with increasing accuracy over time.

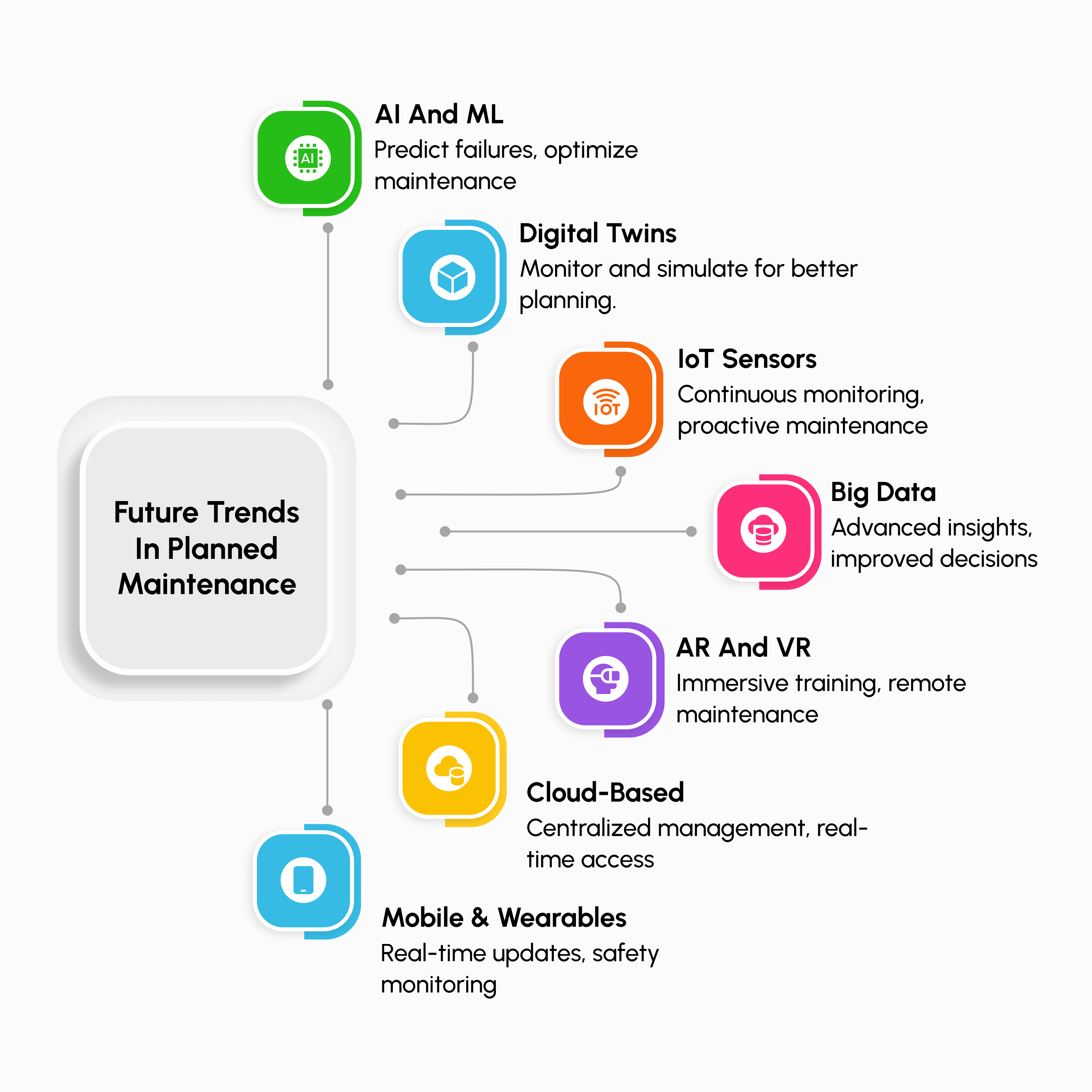

IoT Integration Enables Real-Time Equipment Monitoring

Connect critical assets through advanced IoT sensors for continuous condition monitoring. MaintWiz processes multiple data streams to provide real-time insights into equipment health and performance trends.

Early Warning System Prevents Critical Failures

Detect potential failures weeks in advance through our predictive alert system. Our platform analyzes multiple parameters to identify deteriorating conditions before they lead to breakdowns.

Resource Optimization Through Predictive Planning

Optimize maintenance resource allocation based on predicted equipment needs. Our system balances maintenance schedules with predicted failure risks to maximize resource efficiency.

Continuous Health Monitoring for Critical Assets

Monitor equipment health parameters continuously through integrated sensors and analytics. MaintWiz processes real-time data to maintain optimal performance levels across your asset base.

Machine Learning Enhanced Failure Prevention

Deploy advanced algorithms that continuously improve failure prediction accuracy. Our system learns from each maintenance event to enhance its predictive capabilities over time.

Precision Calibration Management for Quality Assurance

Maintain instrument accuracy and compliance through automated calibration management that ensures precise measurements and quality outputs.

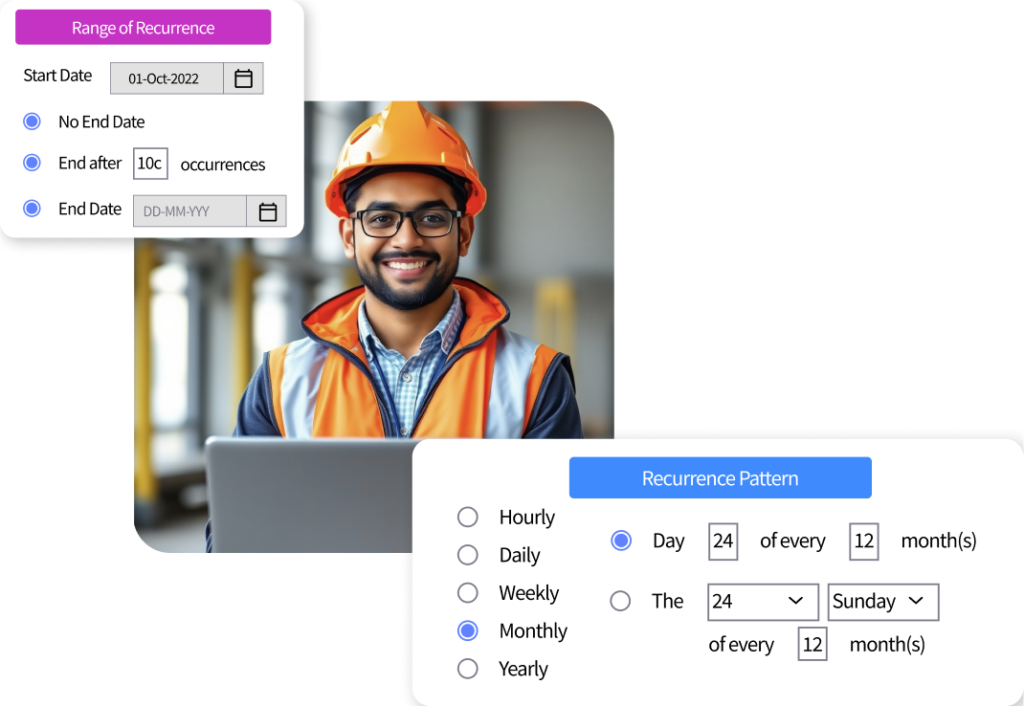

Automated Calibration Schedule Management System

Streamline calibration planning with intelligent scheduling automation. Our system tracks calibration due dates and automatically generates work orders based on equipment specifications and compliance requirements.

Comprehensive Compliance Documentation System

Maintain detailed calibration records that meet regulatory requirements. MaintWiz automatically generates and stores calibration certificates, ensuring complete audit trails for quality compliance.

Precision Maintenance Protocol Implementation

Execute standardized calibration procedures that ensure consistent quality. Our system guides technicians through precise calibration steps while documenting all adjustments and verifications.

Historical Calibration Data Analysis Tools

Track calibration trends and drift patterns through comprehensive analytics. Our platform analyzes historical calibration data to identify instruments requiring special attention or replacement.

Proactive Calibration Alert System

Prevent missed calibrations through automated reminder systems. MaintWiz sends timely notifications to relevant personnel, ensuring critical instruments maintain their accuracy and compliance status.

Custom Calibration Parameter Management

Configure calibration requirements specific to your equipment and quality standards. Our flexible system allows customization of calibration parameters while ensuring compliance with industry standards.

Voices of Our Valued Clients

MaintWiz has optimized our planned maintenance schedule, reducing unplanned downtime significantly

Planned maintenance with MaintWiz has extended equipment lifespan and improved operational efficiency

MaintWiz’s planned maintenance functionality ensures no equipment failure catches us off guard

MaintWiz enables us to plan better, reduce breakdowns, and maintain higher uptime

With MaintWiz, our planned maintenance efforts have been streamlined, reducing costs and downtime.

The proactive approach of MaintWiz’s planned maintenance keeps our operations running without interruptions

MaintWiz’s planned maintenance tools allow us to focus on reliability, not just repairs

We’ve maximized uptime through MaintWiz’s robust planned maintenance system

Optimize Inventory Management for Maintenance Excellence

Transform spare parts management with intelligent inventory control that ensures part availability while optimizing carrying costs.

Real-Time Inventory Monitoring and Control System

Maintain optimal stock levels through automated inventory tracking. Our system provides real-time visibility into spare parts availability while preventing stockouts of critical components.

Intelligent Reorder Point Management

Automate parts ordering through smart reorder triggers. MaintWiz analyzes usage patterns and lead times to maintain optimal inventory levels while minimizing carrying costs.

Seamless SAP Integration for Parts Management

Synchronize spare parts data with your SAP system through our integrated platform. Our solution ensures real-time alignment between maintenance requirements and procurement processes.

Advanced Cost Control Analytics Platform

Monitor and optimize inventory costs through comprehensive analytics. Our system tracks key metrics including carrying costs, turnover rates, and obsolescence risks to guide inventory optimization.

Sophisticated Parts Usage Analysis Tools

Analyze parts consumption patterns to optimize stock levels. MaintWiz provides detailed insights into usage trends, enabling data-driven decisions about inventory management.

Warranty and Lifecycle Tracking System

Manage parts warranties and lifecycle status effectively. Our platform tracks warranty periods and part lifecycles, ensuring optimal utilization of warranty coverage and timely replacements.

Drive Performance Through Advanced Maintenance Analytics

Transform maintenance data into actionable insights through comprehensive analytics and reporting capabilities.

Customizable KPI Dashboard Implementation

Monitor critical maintenance metrics through personalized dashboards. Our platform enables custom KPI tracking that aligns with your specific TPM objectives and organizational goals.

Equipment Health Monitoring and Trend Analysis

Track asset performance through comprehensive health cards. MaintWiz analyzes performance trends to identify deteriorating equipment conditions and guide proactive interventions.

Historical Maintenance Pattern Recognition

Analyze maintenance histories to identify improvement opportunities. Our system provides detailed visualizations of maintenance patterns, enabling data-driven optimization strategies.

Advanced Downtime Analytics Engine

Identify and address sources of equipment downtime effectively. Our analytics engine processes downtime data to highlight critical areas requiring immediate attention or strategic improvements.

Comprehensive Work Order Performance Tracking

Monitor maintenance effectiveness through detailed completion metrics. MaintWiz provides insights into work order execution, enabling continuous improvement of maintenance processes.

ROI Analysis for Maintenance Strategies

Evaluate maintenance program effectiveness through cost-benefit analysis. Our platform tracks maintenance costs against performance improvements to demonstrate clear ROI for your TPM initiatives.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.