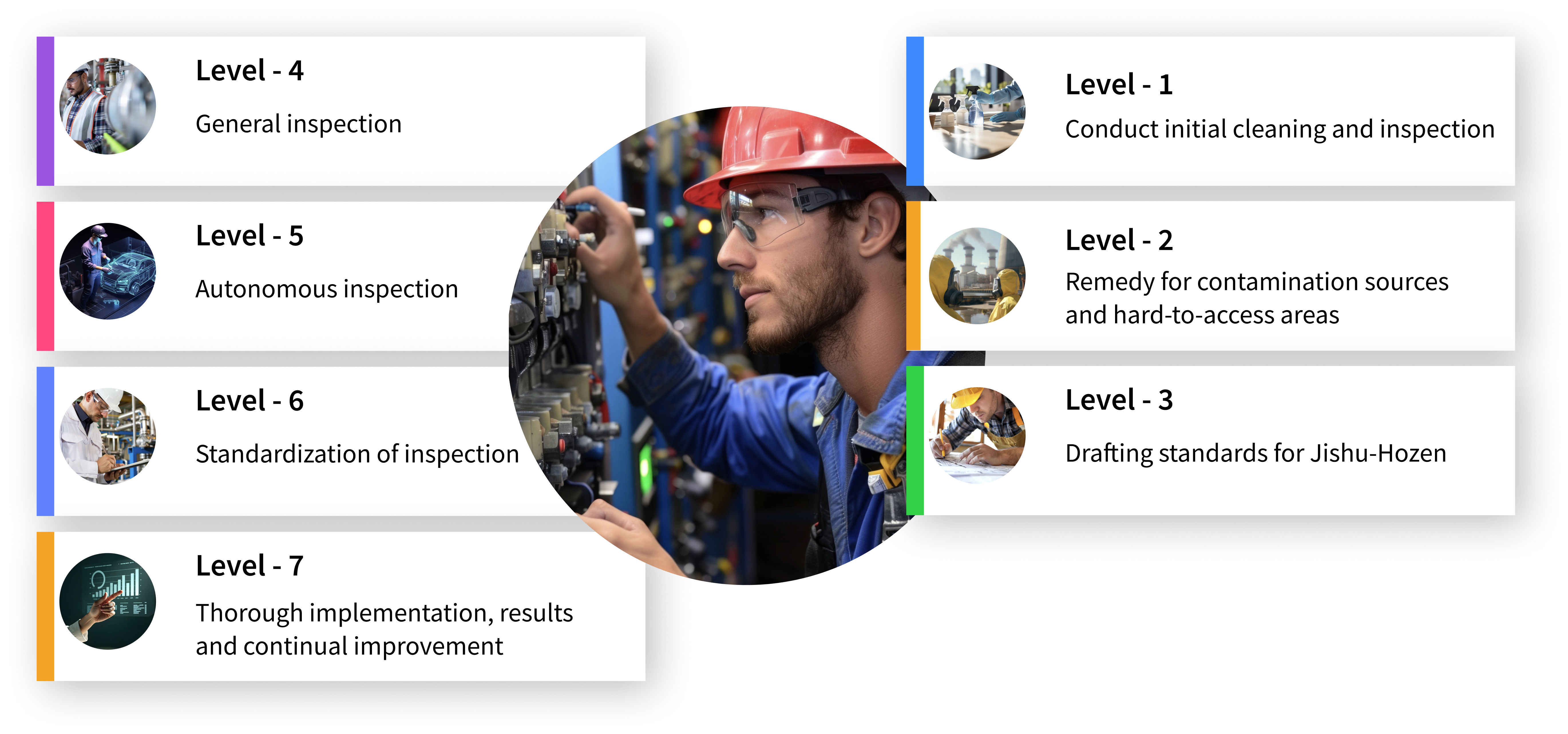

Empower Operators with Digital Autonomous Maintenance Solutions

Transform your TPM implementation with MaintWiz's comprehensive Autonomous Maintenance platform. Enable operator-driven equipment care, eliminate failures, and achieve sustainable manufacturing excellence through digital transformation.

Accelerate Operator - Driven Maintenance Excellence

Transform traditional maintenance approaches into operator-led excellence with digital tools that enhance equipment care and ownership.

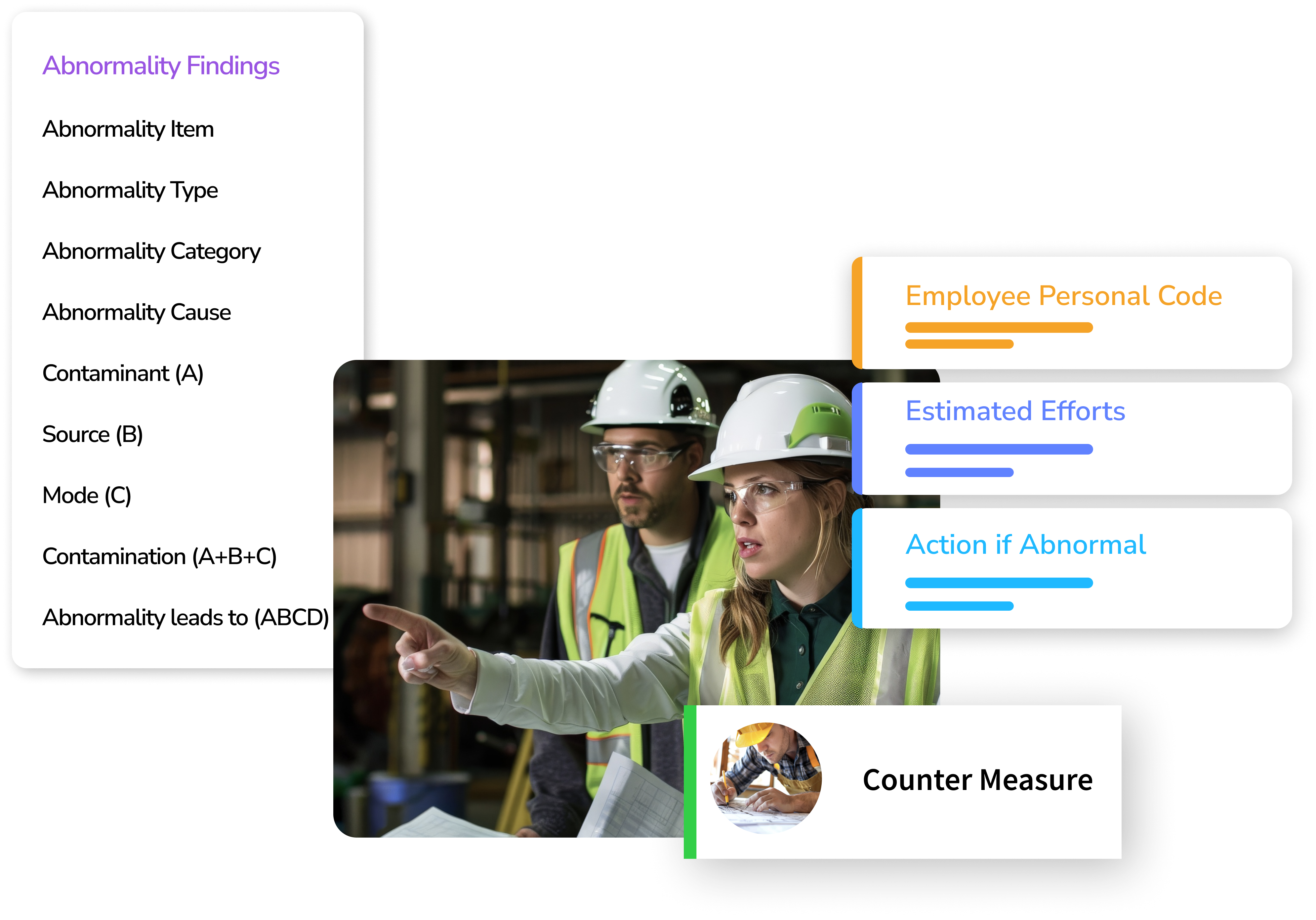

Seamless Digital Logging of Daily Equipment Checks and Tasks

Replace cumbersome paper-based systems with our intuitive digital platform, enabling operators to log maintenance activities instantly, track equipment performance, and maintain comprehensive maintenance histories with just a few taps.

Interactive Self-Service Modules for Equipment Inspections

Empower operators with user-friendly digital modules that guide them through routine checks and inspections. Step-by-step instructions ensure consistent execution while built-in validation ensures thorough completion of all critical steps.

Real-Time Maintenance Updates Through Mobile Interface

Keep operators informed with instant notifications about equipment status, maintenance requirements, and task completion. Our mobile-first approach ensures critical information reaches the right person at the right time.

Dynamic Visual Indicators for Equipment Performance

Monitor equipment health through intuitive visual dashboards that display real-time performance metrics. Color-coded indicators and trend graphs help operators quickly identify potential issues and track improvement initiatives.

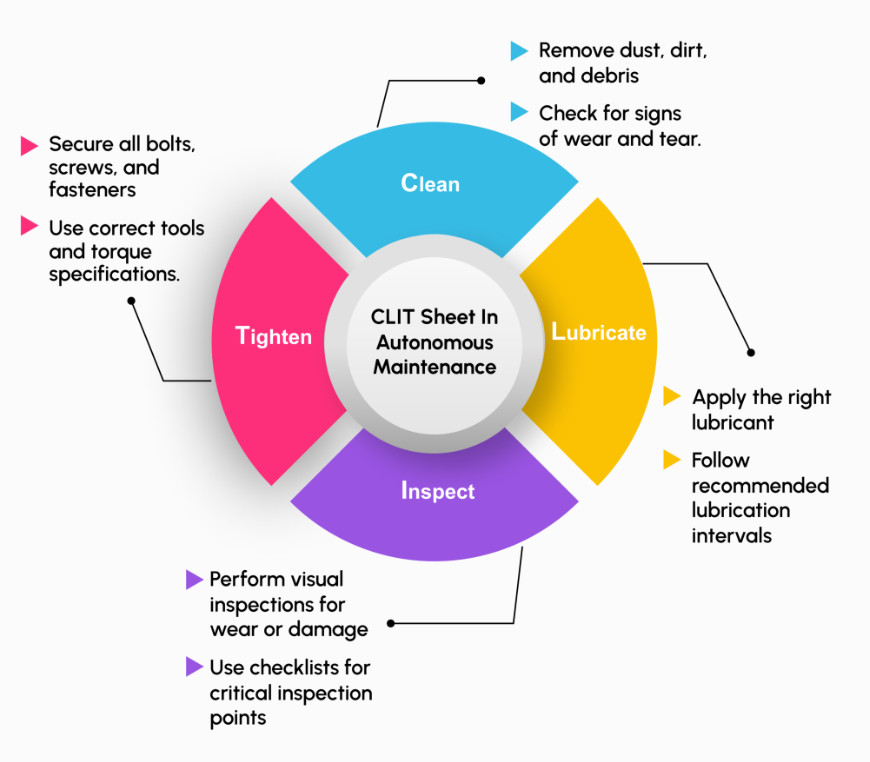

Guided Digital Procedures for Basic Maintenance

Access comprehensive maintenance procedures through interactive digital guides. Visual aids, clear instructions, and best practices ensure operators can confidently perform basic maintenance tasks while maintaining quality standards.

Quick Access Troubleshooting Knowledge Base

Enable operators to resolve common equipment issues independently through our searchable knowledge base. Documented solutions, best practices, and troubleshooting guides reduce dependency on specialized maintenance staff.

Drive Equipment Reliability Through Operator Empowerment

Transform operators into equipment owners with intelligent tools that enhance decision-making and maintenance capabilities.

Intelligent Equipment Status Monitoring System

Monitor equipment health through real-time sensors and intelligent algorithms. Automated alerts notify operators of abnormal conditions, enabling immediate intervention before minor issues escalate into major problems.

Digital Maintenance Checklists with Built-in Validation

Streamline inspection routines with customizable digital checklists. Built-in validation ensures thorough completion while automated tracking maintains comprehensive records of all operator maintenance activities.

Comprehensive Equipment History and Performance Insights

Access detailed equipment histories, maintenance records, and performance trends through our intuitive interface. Historical data and analytics help operators make informed decisions about equipment care and maintenance timing.

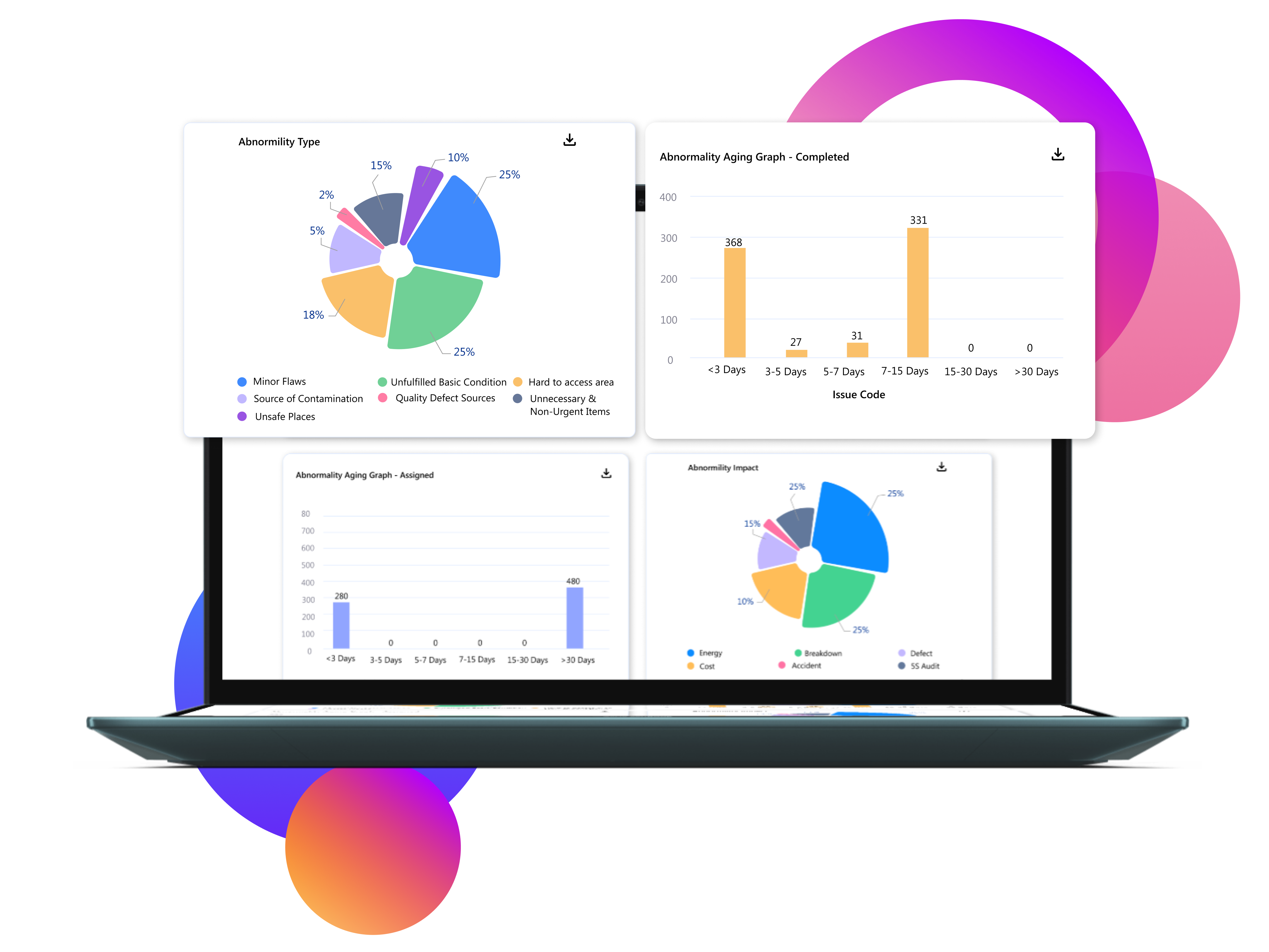

Advanced Analytics for Early Problem Detection

Leverage predictive analytics to identify potential equipment issues before they impact production. Machine learning algorithms analyze performance patterns and alert operators to developing problems.

Automated Task Scheduling and Resource Management

Optimize maintenance timing with intelligent scheduling algorithms that consider production demands, resource availability, and equipment condition. Automated reminders ensure no critical tasks are missed.

Real-Time Equipment Performance Monitoring Tools

Track key performance indicators through customizable dashboards that highlight equipment health and maintenance effectiveness. Real-time data enables operators to optimize equipment care strategies continuously.

Speak to a Specialist

Get personalised advice from our experts

Transform Maintenance Efficiency Through Digital Solutions

Optimize maintenance execution with intelligent tools that streamline workflows and enhance productivity.

Intelligent Scheduling System for Minimal Production Impact

Optimize maintenance timing through advanced scheduling algorithms that minimize production disruption. Smart planning tools consider multiple factors to identify optimal maintenance windows.

Centralized Digital Library of Standard Procedures

Access comprehensive maintenance procedures through our digital library. Standardized workflows, visual guides, and best practices ensure consistent execution while maintaining quality standards.

Mobile-First Platform for On-Site Maintenance

Execute maintenance tasks efficiently with our mobile-optimized platform. Operators can access procedures, log activities, and update status while moving around the facility, eliminating paperwork delays.

Smart Alert System for Scheduled Maintenance

Stay on top of maintenance schedules with intelligent notifications that alert operators to upcoming tasks. Automated reminders and escalation protocols ensure critical maintenance is never missed.

Digital Tracking System for Maintenance Activities

Monitor maintenance execution through comprehensive digital tracking. Real-time status updates, completion verification, and automated documentation maintain accurate records of all maintenance activities.

Automated Feedback Collection and Analysis

Capture operator insights through structured feedback forms integrated into maintenance workflows. Automated analysis identifies trends and improvement opportunities from collected feedback.

Enhance Operational Safety Through Digital Compliance

Maintain highest safety standards with integrated tools that ensure regulatory compliance & safe operations.

Digital Safety Checklists with Compliance Tracking

Ensure operational safety through comprehensive digital checklists that guide operators through required safety protocols. Built-in validation and automated tracking maintain complete compliance records.

Automated Documentation for Regulatory Requirements

Maintain compliance documentation effortlessly with automated record-keeping. Digital storage, instant retrieval, and audit trails ensure all regulatory requirements are met and properly documented.

Digital Pre-Start Safety Verification System

Prevent accidents with mandatory digital pre-start checks. Interactive verification ensures all safety requirements are met before equipment operation, maintaining workplace safety standards.

Real-Time Equipment Usage Compliance Monitoring

Track equipment usage patterns through automated monitoring systems. Real-time alerts highlight potential compliance issues, enabling immediate corrective action to maintain safe operations.

Smart Safety Alert Management System

Manage safety reviews effectively through intelligent alert systems. Automated notifications ensure timely completion of safety checks while escalation protocols handle missed or overdue reviews.

Digital Operator Certification Tracking

Monitor operator qualifications through comprehensive training records. Digital tracking ensures only certified operators perform specific tasks, maintaining safety standards and regulatory compliance.

Voices of Our Valued Clients

MaintWiz empowers operators with Jishu Hozen, giving them control over equipment maintenance

Through MaintWiz, Jishu Hozen has elevated operator responsibility, driving efficiency and reliability.

MaintWiz supports Jishu Hozen by enabling operators to perform effective, routine equipment checks.

MaintWiz’s Jishu Hozen functionality fosters a sense of ownership among operators, enhancing uptime.

Jishu Hozen with MaintWiz gives operators the tools to address issues before they escalate.

With MaintWiz, Jishu Hozen is seamless, allowing operators to maintain equipment with ease.

MaintWiz has brought Jishu Hozen to life, empowering our operators for better maintenance outcomes

MaintWiz makes Jishu Hozen a natural part of our operations, driving consistent reliability.

Optimize Performance Through Data-Driven Insights

Transform maintenance effectiveness with advanced analytics and intelligent problem-solving tools.

Advanced Analytics for Maintenance Pattern Recognition

Identify improvement opportunities through sophisticated analysis of maintenance patterns. Machine learning algorithms detect trends and correlations, enabling proactive maintenance strategies.

Comprehensive Digital Maintenance History Analysis

Access detailed maintenance records through our digital archive. Historical analysis tools help identify recurring issues, evaluate maintenance effectiveness, and optimize future maintenance planning.

Predictive Analytics for Maintenance Optimization

Prevent equipment failures through predictive analytics that identify developing issues. Advanced algorithms analyze performance data to forecast maintenance needs and optimize intervention timing.

Smart Detection of High-Frequency Issues

Identify critical maintenance needs through automated analysis of fault patterns. Intelligent algorithms highlight equipment requiring additional attention, enabling focused improvement initiatives.

Cross-Departmental Data Sharing Platform

Enhance maintenance effectiveness through seamless information sharing across departments. Integrated platforms ensure all stakeholders access current equipment status and maintenance information.

Digital Capture of Operator Insights

Transform operator observations into actionable insights through structured data collection. Automated analysis of operator feedback identifies emerging issues and improvement opportunities.

Maximize Equipment Lifecycle Through Sustainable Practices

Ensure long-term equipment reliability with comprehensive lifecycle management tools.

Digital Wear and Tear Monitoring System

Track equipment condition through comprehensive monitoring tools. Digital sensors and inspection records provide detailed insights into wear patterns, enabling proactive maintenance interventions.

Equipment-Specific Maintenance Recommendations

Optimize equipment care through customized maintenance protocols. Asset-specific guidelines and best practices ensure appropriate maintenance strategies for each equipment type.

Intelligent Maintenance Timing Optimization

Schedule maintenance activities through smart algorithms that consider equipment condition, production demands, and resource availability. Optimal timing reduces costs while maximizing equipment life.

Strategic Asset Management Analytics

Plan equipment lifecycle strategies through comprehensive analytics. Long-term trend analysis and performance data guide strategic decisions about equipment maintenance and replacement timing.

Energy Efficiency Monitoring and Optimization

Reduce operational costs through intelligent energy monitoring. Real-time tracking and analysis identify opportunities for energy optimization while maintaining equipment performance.

Cost Reduction Through Preventive Maintenance

Minimize repair costs through effective preventive maintenance strategies. Data-driven maintenance optimization reduces unexpected failures and extends equipment life, delivering substantial cost savings.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.