Build Sustainable 5S Foundation for TPM Excellence with MaintWiz CMMS

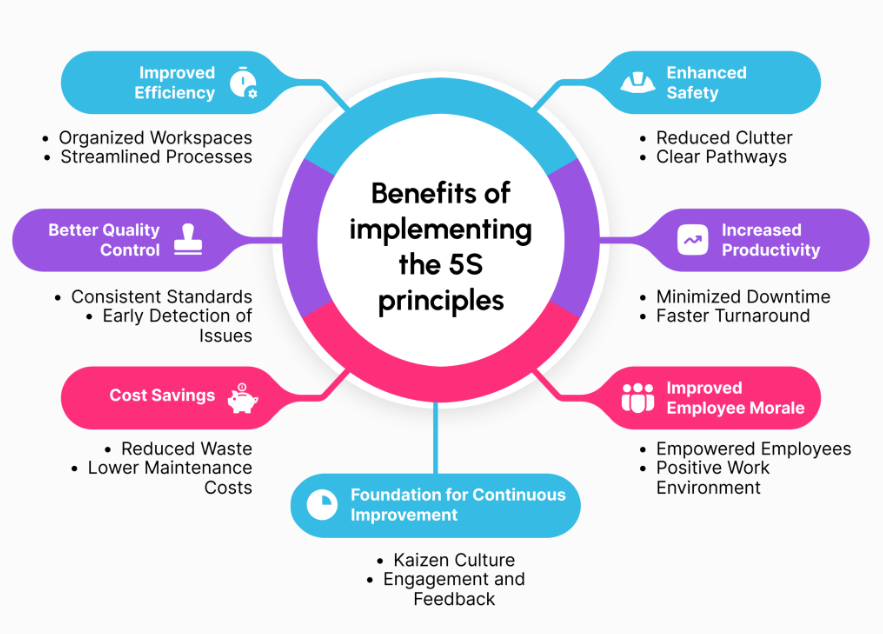

Transform your TPM implementation with MaintWiz CMMS's comprehensive 5S digital platform. Create structured workplace organization, establish visual management systems, and build operational excellence through systematic automation.

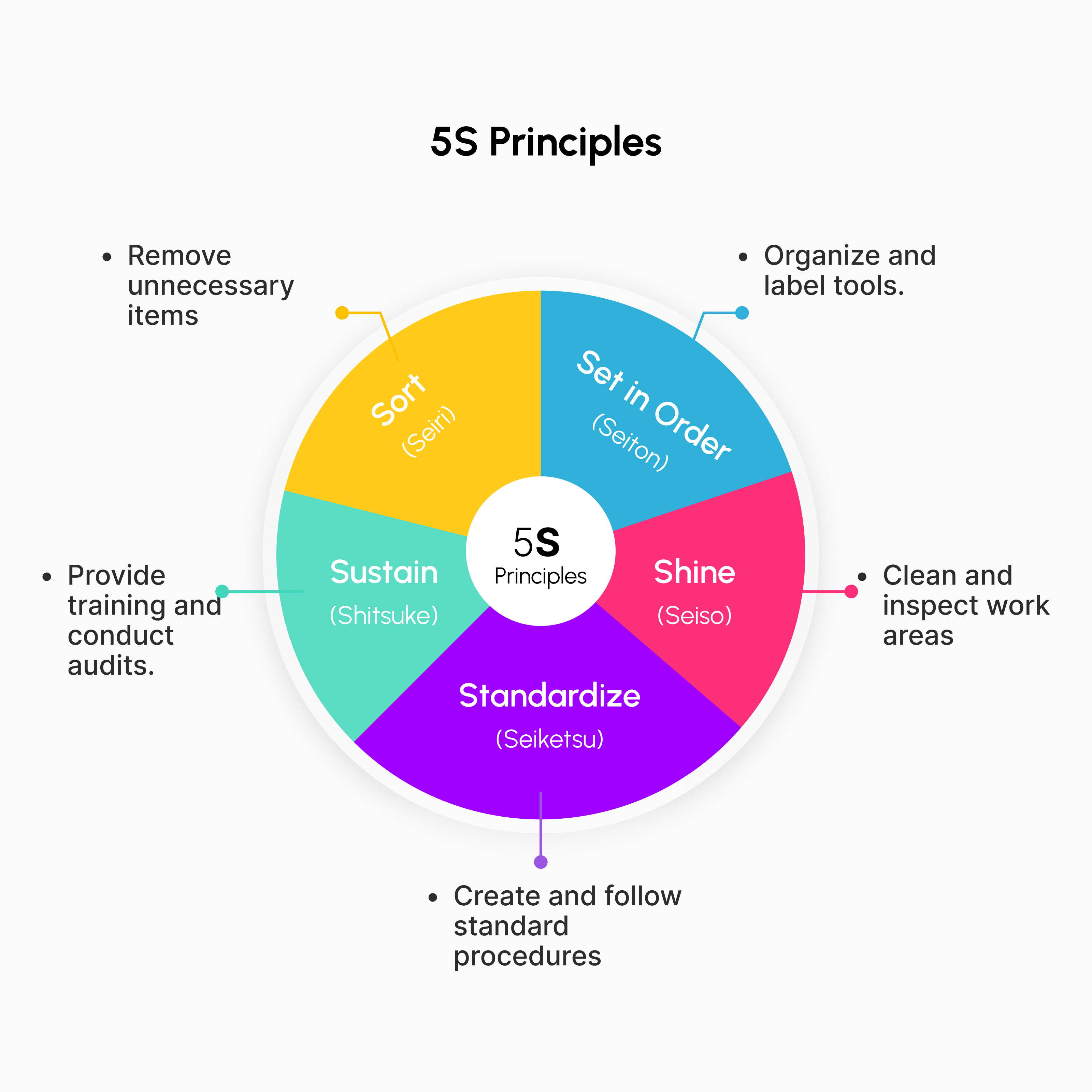

Strengthen TPM Foundation with Systematic Sort Management

Create structured workplace organization through systematic sorting solutions that establish clear baseline for TPM implementation and enhance operational efficiency.

Comprehensive Asset Registry Drives Effective Sort Implementation

Build detailed equipment and tool databases that enable systematic identification of necessary vs unnecessary items, establishing clear baselines for workplace organization and TPM implementation.

Digital Red-Tag Management Streamlines Sort Activities

Systematize red-tag processes with customizable workflows, ensuring proper evaluation of items while maintaining detailed records for continuous improvement and TPM audits.

Inventory Analytics Enable Data-Driven Sort Decisions

Leverage usage tracking and inventory reports to make informed decisions about equipment retention, optimizing resource allocation while maintaining operational efficiency.

Systematic Categorization Enhances Workplace Organization

Implement structured categorization systems that analyze equipment criticality and usage patterns, establishing clear organization protocols aligned with TPM objectives.

Mobile-Enabled Sort Operations Support Team Collaboration

Equip teams with mobile access to sorting guidelines and checklists, enabling coordinated sort activities and immediate documentation of workplace organization initiatives.

Performance Tracking for Sort Implementation

Monitor sort activity effectiveness through systematic metrics tracking, providing clear visibility into workplace organization improvements and impact on TPM implementation.

Establish Visual Management with Set-in-Order Solutions

Create efficient visual management systems through structured location tracking and workplace organization tools that support TPM implementation.

Location Management System Enhances Visual Control

Implement systematic tool and equipment tracking using barcodes and location tags, creating clear visual management systems that reduce search times and support TPM activities.

Visual Factory Dashboard Strengthens Workplace Organization

Deploy customizable visual management boards showing real-time equipment status and location data, ensuring optimal workspace organization for TPM implementation.

Systematic Space Optimization for TPM Activities

Analyze workflow patterns to optimize equipment and tool placement, maximizing workspace efficiency while supporting systematic TPM implementation requirements.

Digital Shadow Board Management Ensures Organization

Create and maintain digital tool organization systems with automated compliance tracking, ensuring consistent workplace organization standards for TPM activities.

Structured Navigation Support for Efficient Operations

Enable quick asset location through systematic navigation guides, helping teams efficiently locate tools and equipment while maintaining organized workspaces for TPM.

Space Utilization Analytics Drive Continuous Improvement

Track workspace efficiency through systematic monitoring tools that measure space utilization and suggest improvements based on TPM implementation needs.

Speak to a Specialist

Get personalised advice from our experts

Build TPM Culture through Systematic Shine Activities

Establish cleaning and inspection standards through structured scheduling and tracking systems that create foundation for autonomous maintenance.

Structured Cleaning Schedule Management System

Organize cleaning routines with systematic scheduling tools that optimize resource allocation, track completion rates, and establish baseline for autonomous maintenance activities.

Inspection Integration Platform Supports TPM Implementation

Connect cleaning activities with maintenance inspections, enabling early problem detection while building operator ownership through systematic workplace management.

Digital Cleanliness Audit System Ensures Standards

Streamline inspection processes with structured checklists and evaluation systems, ensuring consistent standards and supporting development of autonomous maintenance capabilities.

Systematic Condition Monitoring for Equipment

Deploy structured monitoring systems to track equipment cleanliness levels, automatically logging maintenance needs and supporting proactive TPM implementation.

Mobile Cleaning Verification Enhances Team Engagement

Provide teams with mobile tools for cleaning verification, enabling systematic documentation of activities while building ownership for workplace organization.

Shine Performance Analytics Drive Improvement

Monitor cleaning effectiveness through structured analytics, tracking key metrics that demonstrate progress in building autonomous maintenance capabilities.

Standardize Operations for TPM Excellence

Create standardized operating procedures with digital systems and compliance monitoring that establish foundation for consistent TPM implementation.

Centralized SOP Management Ensures Consistency

Manage procedures through centralized systems ensuring immediate access to standards, maintaining version control while enabling systematic updates across facilities.

Standards Compliance Monitoring Supports TPM

Track adherence to standardized procedures through systematic checkpoints, providing clear visibility into compliance levels and supporting TPM implementation efforts.

Digital Work Instruction System Builds Capability

Deploy clear work instructions with visual aids, ensuring consistent task execution while developing team capabilities for autonomous maintenance activities.

Best Practice Sharing Promotes TPM Culture

Enable knowledge transfer across facilities through systematic sharing of best practices, driving continuous improvement and strengthening TPM implementation.

Training Integration Develops Team Competency

Connect procedures directly to training modules, building workforce competency while maintaining detailed records of TPM procedure implementation.

Process Analytics Support TPM Implementation

Monitor standardization effectiveness through systematic analytics, identifying areas for procedure optimization and measuring impact on TPM performance.

Voices of Our Valued Clients

MaintWiz helps us maintain impeccable standards, allowing 5S to be part of our DNA

Through MaintWiz, we’ve embedded 5S into our maintenance practices for ongoing excellence.

MaintWiz’s 5S tools have revolutionized our workplace, driving organization and efficiency

Using MaintWiz, 5S principles have empowered our teams to sustain a cleaner, safer workplace

MaintWiz helped us implement 5S effectively, reducing waste and increasing operational flow.

With MaintWiz, we’ve streamlined our 5S implementation, ensuring long-term sustainability and order

MaintWiz makes it easy to maintain a 5S culture, optimizing productivity and safety.

The 5S foundation powered by MaintWiz has transformed our entire production environment.

MaintWiz helps us maintain impeccable standards, allowing 5S to be part of our DNA

Through MaintWiz, we’ve embedded 5S into our maintenance practices for ongoing excellence.

MaintWiz’s 5S tools have revolutionized our workplace, driving organization and efficiency

Using MaintWiz, 5S principles have empowered our teams to sustain a cleaner, safer workplace

Sustain TPM Excellence through Systematic Management

Build lasting TPM culture through structured engagement tools and performance analytics that ensure sustained workplace organization excellence.

Team Engagement Platform Strengthens TPM Culture

Foster continuous improvement through structured suggestion systems and recognition programs that encourage active participation in maintaining TPM standards.

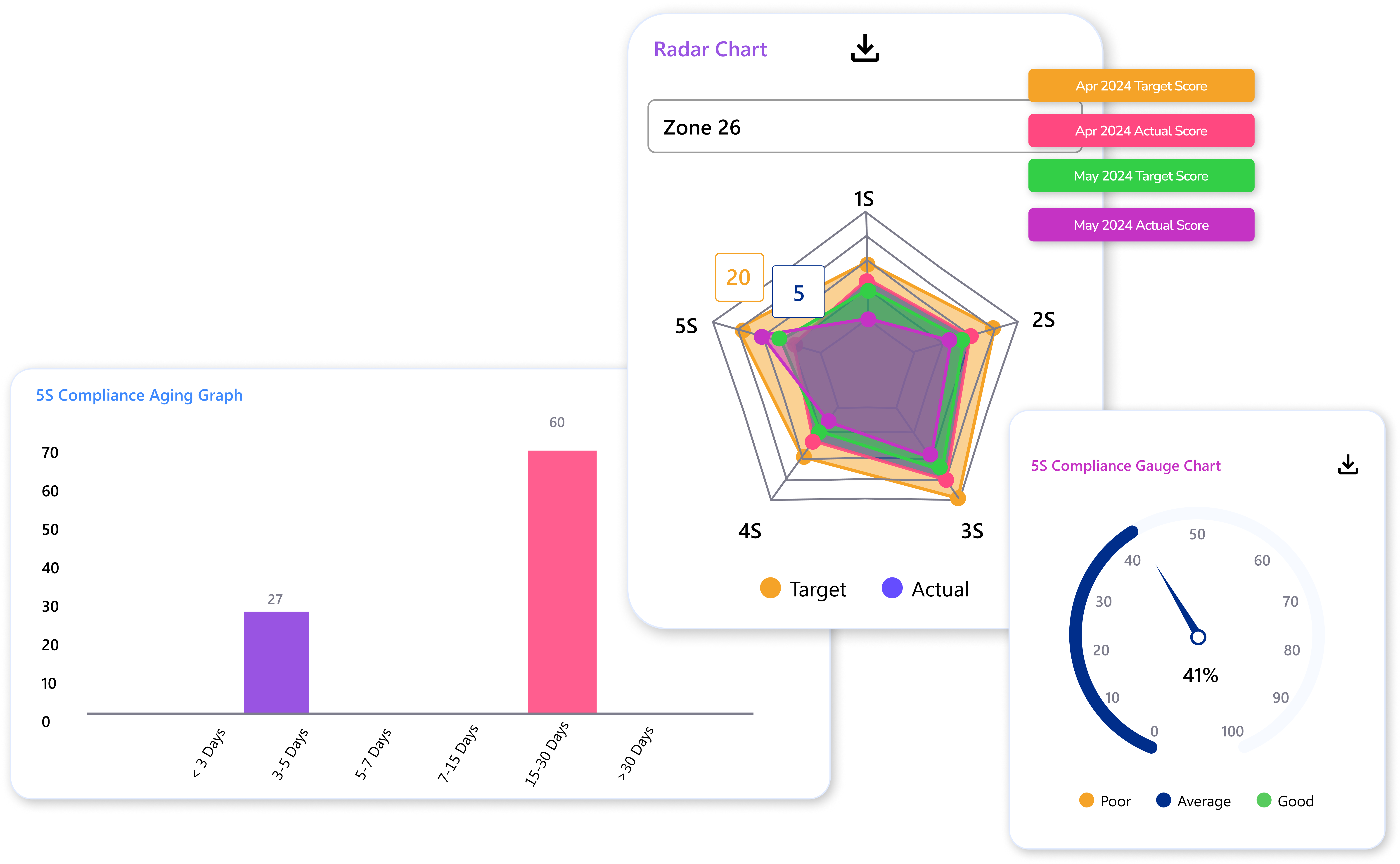

Performance Analytics Drive TPM Excellence

Measure initiative impact through comprehensive dashboards tracking key metrics including productivity improvements, equipment reliability, and workplace organization.

Systematic Audit Management Ensures Compliance

Maintain TPM momentum through structured audit schedules and scoring systems that ensure consistent evaluation and sustained program effectiveness.

Recognition System Promotes TPM Culture

Motivate continued participation through systematic recognition programs that reward sustained commitment to workplace organization and TPM excellence.

Progress Tracking Platform Shows TPM Impact

Monitor long-term program effectiveness through systematic trend analysis, ensuring sustained improvement in workplace organization and equipment reliability.

Culture Development Analytics Guide Implementation

Track organizational transformation through structured metrics measuring team engagement, participation rates, and overall TPM program adoption.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.