Digital Maintenance Mastery: Total Productive Maintenance Redefined

Bridge the gap between traditional maintenance practices and Industry 4.0 innovation. Our comprehensive TPM solution integrates cutting-edge technologies, predictive analytics, and holistic TPM principles to transform your maintenance ecosystem and drive competitive advantage.

Total Productive Maintenance: Your Competitive Advantage Catalyst

Navigate the complex landscape of modern manufacturing with a comprehensive maintenance strategy that goes beyond traditional approaches. Integrate cutting-edge TPM principles to reduce downtime, optimize asset performance, and drive continuous operational excellence across your enterprise.

Optimize Equipment Performance and Lifespan

Track, manage, and optimize asset performance with real-time data and maintenance schedules. Ensuring your equipment operates at peak efficiency is critical for achieving your TPM goals, and MaintWiz TPM Solution is designed to help you do just that.

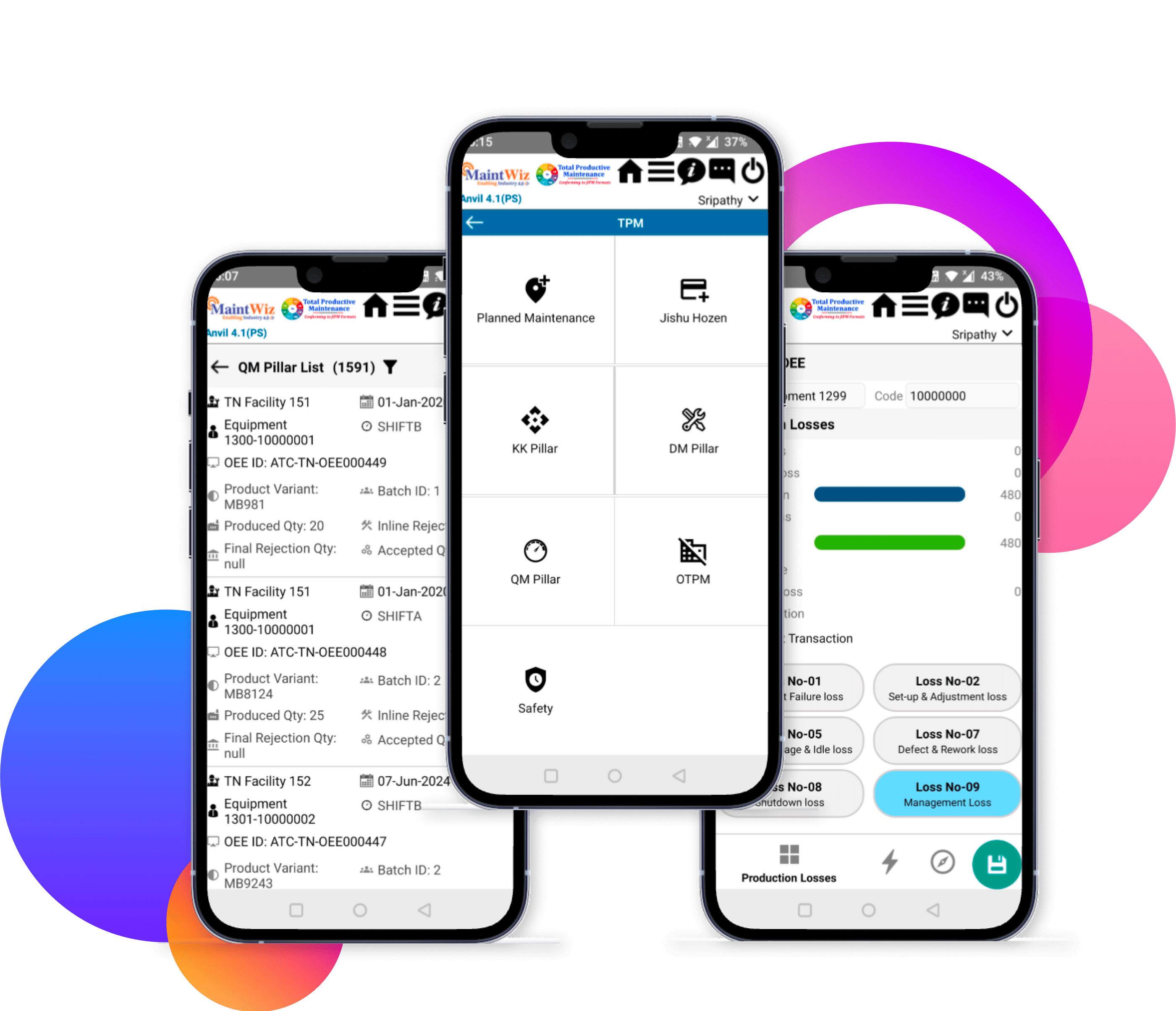

Effortless TPM Integration with CMMS Workflows

MaintWiz TPM Solution supports seamless integration with your existing maintenance workflows. By embedding TPM principles directly into your system, you can ensure consistency in maintenance activities and unlock significant improvements in operational performance.

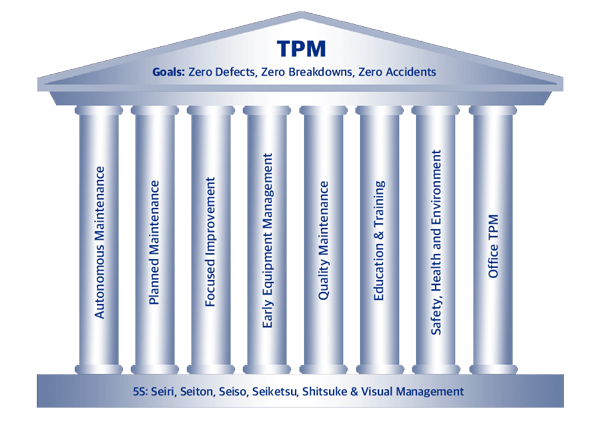

Build a Strong 5S Foundation with MaintWiz TPM

Implementing the 5S methodology is key to creating a safe and efficient workplace. MaintWiz TPM Solution empowers you to establish a culture of organization, cleanliness, and safety, enabling higher employee engagement and enhanced productivity.

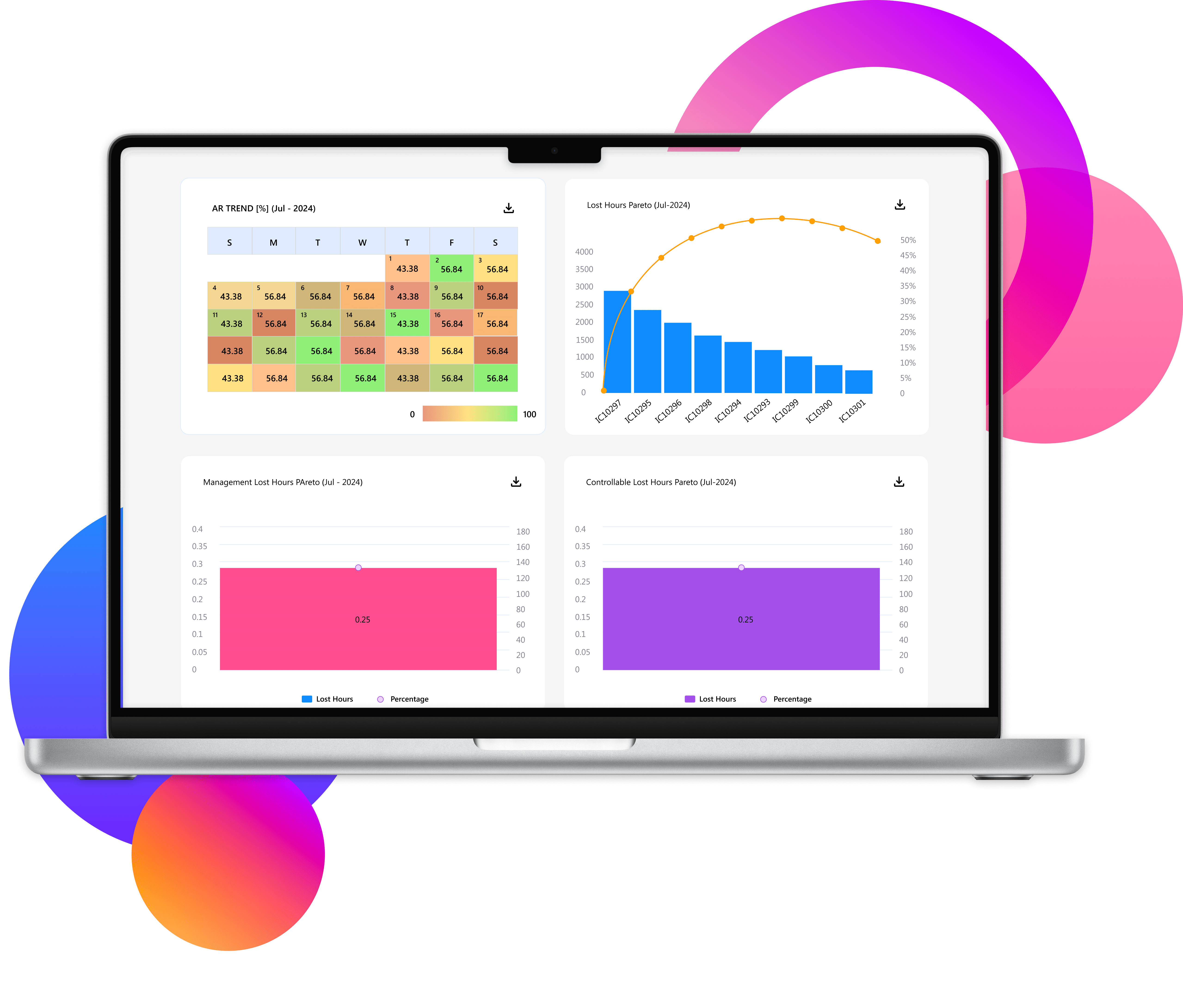

Detailed Reporting & Analytics for Ongoing Improvement

Access Detailed Reports and Metrics for Smarter Decision-Making. Gain full visibility into your maintenance operations with detailed reporting and analytics. The insights derived from MaintWiz TPM Solution allow you to identify areas for improvement, track performance, and make informed decisions that enhance operational efficiency.

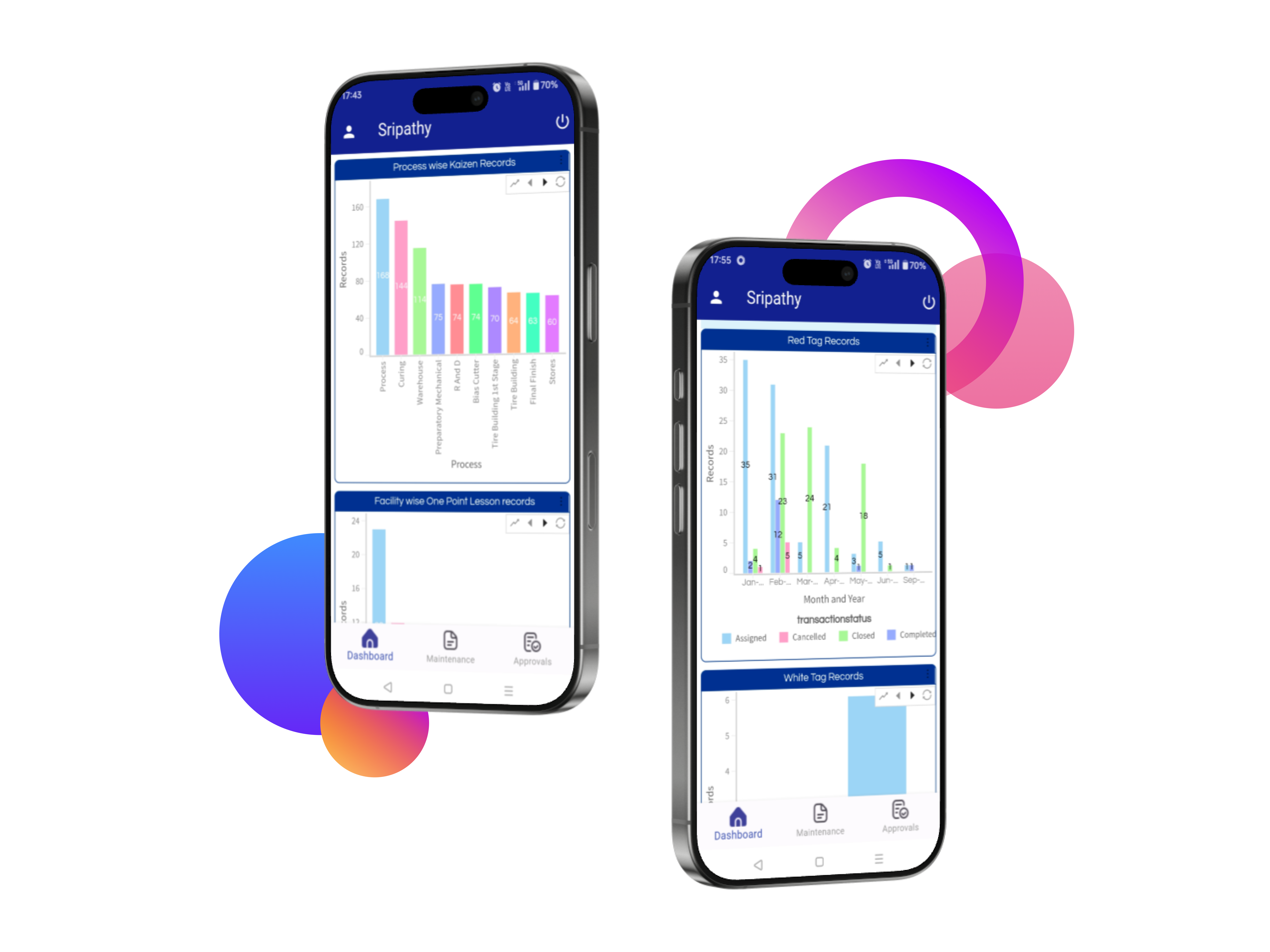

Implement Kaizen, RCA, & OPL to Foster Continuous Improvement

Leverage Lean Principles and Root Cause Analysis for Excellence. Integrate Kaizen, Root Cause Analysis (RCA), and Operator Performed Inspections (OPL) into your TPM strategy with MaintWiz TPM Solution. Use data to continuously refine processes, eliminate waste, and improve both product quality and operational performance.

Achieve Full Adherence to TPM Principles with MaintWiz TPM Solution

Ensure Consistent TPM Implementation Across Your Operations. MaintWiz TPM Solution ensures that your entire organization adheres to TPM principles. Achieve zero downtime, zero defects, and zero accidents by automating maintenance tasks, improving training, and empowering employees to take ownership of equipment.

Maximize Uptime, Minimize Failures

MaintWiz TPM Solution helps you achieve zero downtime by proactively identifying potential issues through predictive maintenance and real-time alerts. Preventive and predictive maintenance strategies keep your operations running smoothly.

Achieve High-Quality Standards Everywhere

With MaintWiz TPM Solution, monitor and maintain strict quality control standards to ensure zero defects in your products. Proactive maintenance and real-time performance monitoring lead to improved product quality and reduced rework.

Boost Safety, Minimize Risks

MaintWiz TPM Solution helps you maintain a safe working environment by automating safety checks, training programs, and regular inspections. With continuous monitoring, accidents are minimized, ensuring a safer, more productive workplace.

Empower Operators with Maintenance Ownership

Empower your operators with the tools to take charge of maintenance tasks. MaintWiz TPM Solution fosters a culture of ownership and accountability, improving maintenance efficiency and ensuring adherence to TPM practices.

Ensure Consistent Maintenance Through Standardization

Standardizing maintenance tasks and processes across your organization is critical for consistent TPM implementation. MaintWiz TPM Solution ensures that best practices are followed, providing you with the tools to create and enforce standardized maintenance procedures.

Enhance Safety and Ensure Quality

MaintWiz TPM Solution promotes a culture of safety by integrating safety protocols into daily operations. You can track compliance, monitor risk areas, and improve the overall safety standards across all levels of the organization.

Speak to a Specialist

Get personalised advice from our experts

TPM Meets Industry 4.0: Advanced CMMS for the Digital Era

Transform Your Maintenance Strategy with Industry 4.0-Compatible TPM Solutions. Stay ahead in the digital era with MaintWiz TPM Solution, designed to support Industry 4.0 initiatives. Leverage IoT integration, predictive maintenance, and advanced analytics to optimize your TPM strategy and boost your operational efficiency.

Seamless Integration with SAP and Enterprise Systems

MaintWiz TPM Solution seamlessly integrates with SAP and other enterprise systems, enabling you to streamline operations and maintain full control over your maintenance workflows. Achieve greater visibility and collaboration across departments.

IoT Monitoring for Real-Time Data and Enhanced TPM

IoT-enabled sensors integrated into your assets provide real-time data that supports proactive maintenance and improves decision-making. With MaintWiz TPM Solution, you can monitor asset health and optimize maintenance strategies based on live data.

Advanced Analytics for Real-Time Metrics and Smarter Decisions

Use advanced analytics to track key metrics like Overall Equipment Effectiveness (OEE), downtime, and asset performance. MaintWiz TPM Solution empowers you with actionable insights to drive continuous improvement and optimize operations.

Maximize Asset Lifespan and Boost Performance Effectively

With MaintWiz TPM Solution, manage your assets throughout their entire lifecycle. From installation to decommissioning, ensure your assets are maintained efficiently, extending their useful life and maximizing their return on investment.

Mobile CMMS for Instant Access to Field Teams Anytime

Equip your field technicians with mobile access to work orders, asset data, and maintenance schedules. MaintWiz TPM Solution’s mobile-first approach allows your team to make informed decisions and perform maintenance tasks efficiently, no matter where they are.

AI-Powered Predictive Maintenance for Smarter Reliability

MaintWiz TPM Solution leverages AI and machine learning to predict equipment failures before they occur. By analyzing patterns and trends, our system automates maintenance scheduling and enhances asset reliability, ensuring minimal unplanned downtime.

Achieve OEE Excellence with TPM-Integrated CMMS Solutions

Boost Operational Efficiency and Maximize Equipment Performance Using TPM and OEE. MaintWiz TPM Solution integrates OEE metrics with your TPM strategy, enabling you to monitor and optimize equipment availability, performance, and quality. This combination of TPM and OEE ensures that you achieve maximum efficiency and minimal downtime.

OEE Metrics for Enhanced Asset Performance Monitoring

With OEE metrics integrated into your MaintWiz TPM Solution, you can track key performance indicators at the equipment, line, and plant levels. Use this data to continuously optimize asset performance and eliminate inefficiencies.

Real-Time Data for Smarter Maintenance Decisions

Use real-time data from your TPM and OEE systems to make proactive decisions that improve maintenance efficiency. With live metrics and alerts, you can identify and address issues before they escalate, minimizing downtime and improving asset performance.

Maximize Equipment Uptime with Predictive Maintenance

MaintWiz TPM Solution helps you predict and prevent equipment failures before they happen. With predictive maintenance capabilities, you can optimize equipment uptime and avoid costly breakdowns, enhancing overall operational performance.

Analyze Asset Performance to Enhance Maintenance Strategies

Use in-depth asset reliability and performance analysis to identify underperforming assets. MaintWiz TPM Solution helps you optimize maintenance strategies, ensuring that your assets continue to perform at their best throughout their lifecycle.

Boost Workforce Collaboration to Improve OEE

Promote collaboration between maintenance, operations, and engineering teams with MaintWiz TPM Solution. By sharing data and insights, these teams can work together to identify opportunities for improving OEE and driving operational excellence.

Drive Continuous Improvement with TPM and OEE Data

MaintWiz TPM Solution fosters a culture of continuous improvement by using feedback loops. By analyzing TPM and OEE data, you can refine processes, eliminate waste, and drive operational efficiency across your organization.

8 Pillars of TPM

Total Productive Maintenance (TPM) is based on eight pillars, which are essential for achieving its objectives. Here is a brief description of each pillar:

Key features of Total Productive Maintenance (TPM)

Discover our comprehensive, integrated solutions, to unify your maintenance operations. Derive real-time insights from KPI dashboards, to make informed maintenance decisions and enhance operational efficiency. Experience how our unified platform enhances asset performance, collaboration, streamlines operations, and drives efficiency across all maintenance activities.

Voices of Our Valued Clients

MaintWiz digitalized our TPM processes, maximizing uptime and efficiency like never before!

A game-changer for our TPM journey—MaintWiz streamlined our processes and improved equipment reliability.

MaintWiz’s intuitive platform has streamlined our entire TPM strategy, delivering unmatched maintenance success.

With MaintWiz, we've accelerated our TPM goals, boosting equipment reliability and overall operational efficiency

MaintWiz is a powerful tool that has taken our TPM practices to the next level, improving overall efficiency

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.

Company