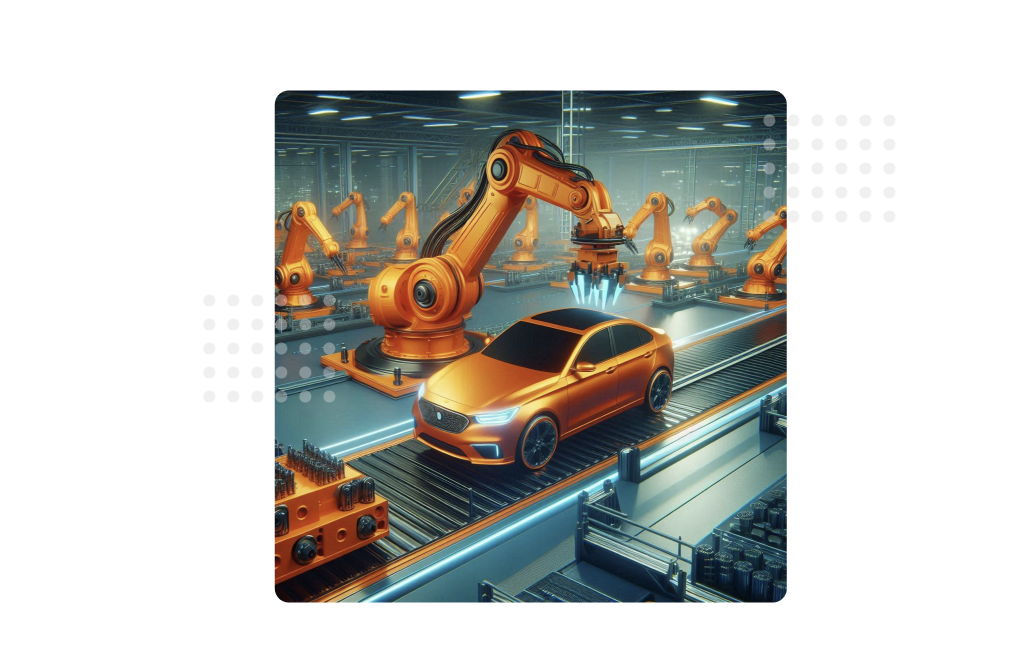

Elevate Discrete Manufacturing with MaintWiz AI CMMS

Unlock peak performance in your discrete manufacturing operations with MaintWiz AI CMMS. Boost equipment reliability, streamline maintenance workflows, and drive productivity to new heights in your production lines.

Transformative Benefits of MaintWiz AI CMMS for Discrete Manufacturing

Maximize Uptime with Predictive Maintenance Strategies

Harness the power of AI to forecast equipment failures and optimize maintenance schedules, ensuring uninterrupted production flows.

Real-time Equipment Health Monitoring:

Leverage IoT sensors and AI analytics to continuously assess machine conditions, catching potential issues before they escalate into costly breakdowns.

Intelligent Maintenance Scheduling Optimization:

Balance production demands with maintenance needs using AI-driven algorithms, minimizing disruptions while maximizing equipment lifespan and performance.

Predictive Failure Analysis for Critical Assets:

Utilize machine learning models to identify patterns in equipment behavior, predicting failures with unprecedented accuracy and lead time.

Automated Work Order Generation and Prioritization:

Streamline maintenance workflows with AI-powered work order creation, ensuring critical tasks are addressed promptly and efficiently.

Enhance Overall Equipment Effectiveness (OEE)

Drive continuous improvement in your manufacturing processes by optimizing the three pillars of OEE: availability, performance, and quality.

Real-time OEE Monitoring and Analysis:

Gain instant visibility into your production line’s efficiency with live OEE tracking, identifying bottlenecks and improvement opportunities on the fly.

AI-Driven Root Cause Analysis:

Quickly pinpoint the underlying causes of efficiency losses with advanced analytics, enabling rapid and targeted corrective actions.

Automated Performance Benchmarking:

Compare equipment and line performance against industry standards and internal benchmarks, driving continuous improvement initiatives.

Prescriptive Maintenance for OEE Optimization:

Receive AI-generated recommendations for maintenance actions that will have the most significant impact on overall OEE scores.

Top Companies in India & Abroad Trust MaintWiz CMMS

Streamline Inventory Management for Maintenance

Optimize your spare parts and maintenance supplies inventory, reducing carrying costs while ensuring critical components are always available.

AI-Powered Inventory Forecasting:

Predict spare part needs with remarkable accuracy, balancing stock levels to minimize both stockouts and excess inventory.

Automated Reorder Point Optimization:

Dynamically adjust reorder points based on usage patterns, lead times, and criticality, ensuring optimal inventory levels at all times.

Digital Twin Integration for Parts Tracking:

Utilize digital twin technology to track the lifecycle of components, optimizing replacement schedules and reducing unnecessary part changes.

Vendor Performance Analytics:

Analyze supplier reliability and part quality metrics to make data-driven decisions on sourcing and vendor relationships.

Speak to a Specialist

Get personalised advice from our experts

Ensure Regulatory Compliance and Quality Control

Maintain rigorous adherence to industry standards and regulations while streamlining quality assurance processes.

Automated Compliance Documentation Generation:

Generate comprehensive reports for ISO 9001, ISO 14001, and other relevant standards with a single click, ensuring audit readiness.

Real-time Quality Metrics Tracking:

Monitor key quality indicators in real-time, enabling swift corrective actions to maintain product excellence and minimize waste.

Digital Audit Trail for Traceability:

Maintain a complete digital record of all maintenance and quality control activities, ensuring full traceability for regulatory compliance.

AI-Enhanced Quality Prediction Models:

Leverage machine learning to predict potential quality issues based on equipment performance data, enabling proactive quality management.

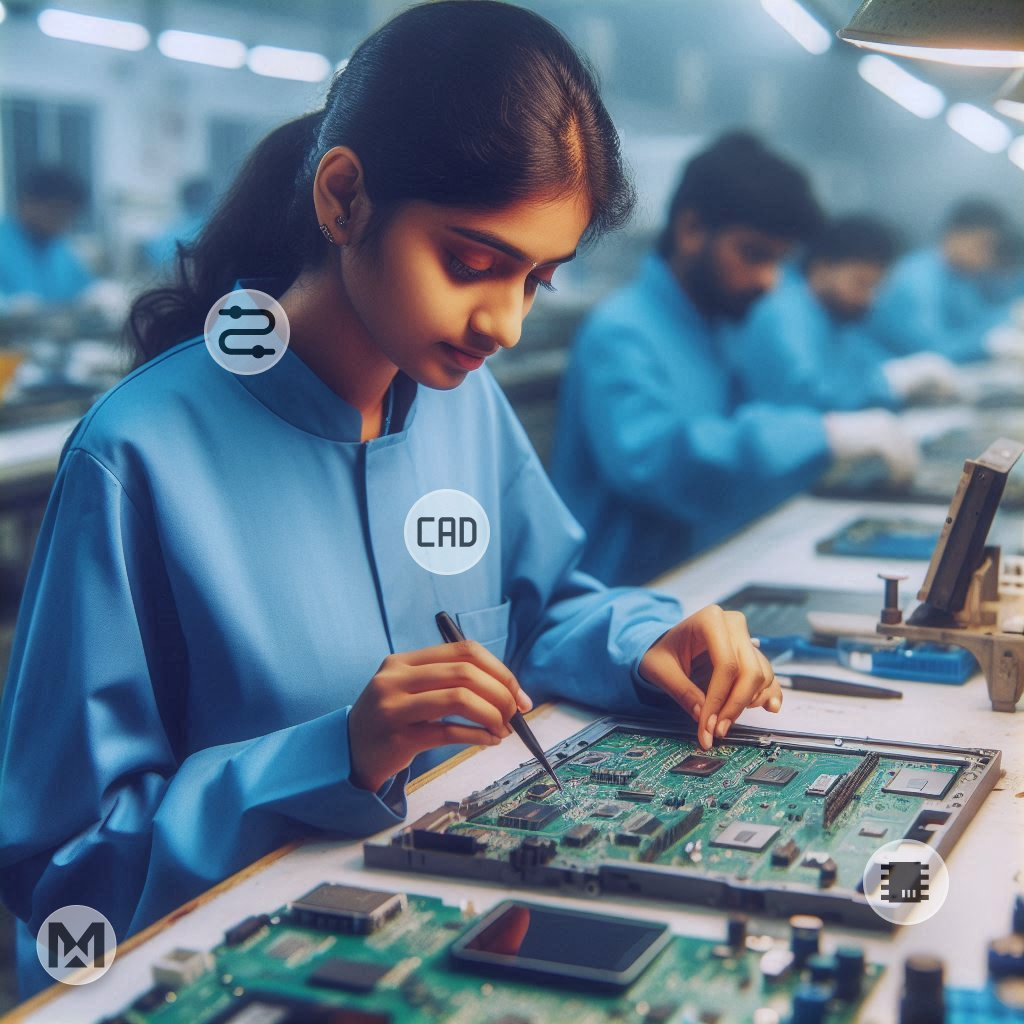

Empower Your Workforce with Mobile-First Solutions

Equip your maintenance team with powerful, user-friendly mobile tools to boost productivity and responsiveness.

Intuitive Mobile Work Order Management:

Enable technicians to access and update work orders on-the-go, reducing administrative overhead and improving response times.

Augmented Reality Guided Repairs:

Provide step-by-step visual guidance for complex repairs using AR technology, reducing errors and accelerating maintenance tasks.

Real-time Collaboration and Knowledge Sharing:

Facilitate instant communication between technicians and experts, leveraging collective knowledge to solve issues faster.

Mobile-Enabled Asset and Inventory Scanning:

Streamline asset audits and inventory checks with mobile scanning capabilities, ensuring accurate and up-to-date records.

Why MaintWiz AI CMMS is the Cornerstone of Smart Manufacturing

Experience unparalleled efficiency and innovation in your discrete manufacturing operations with our cutting-edge CMMS solution.

Comprehensive Coverage Across Your Manufacturing Ecosystem

MaintWiz AI CMMS delivers targeted solutions for each critical domain of utility operations, ensuring seamless service delivery from generation to end-user distribution.

Production Lines

- Optimize preventive maintenance schedules to maximize uptime

- Monitor real-time OEE metrics for continuous improvement

- Implement predictive maintenance to prevent unexpected breakdowns

- Streamline changeover processes with AI-optimized procedures

Quality Control Stations

- Automate quality check scheduling and documentation

- Track and analyze defect rates for process improvement

- Integrate with CMM and other inspection equipment

- Generate compliance reports for ISO 9001 and industry standards

Tooling and Fixtures Interface

- Monitor tool wear and automate replacement scheduling

- Track calibration needs and certifications

- Optimize tool inventory and usage patterns

- Implement digital twin technology for lifecycle management

Material Handling Systems

- Ensure timely maintenance of conveyors and AGVs

- Optimize routing and scheduling of material flow

- Monitor energy consumption for sustainability initiatives

- Implement predictive maintenance for critical components

Seamless Integration for Holistic Manufacturing Intelligence

MaintWiz AI CMMS offers robust integration capabilities, creating a unified ecosystem for your discrete manufacturing operations.

ERP System Synchronization:

Seamlessly connect maintenance data with your enterprise resource planning system, enabling comprehensive financial and operational planning across your organization.

Manufacturing Execution System (MES) Integration:

Seamlessly integrate geospatial data with maintenance workflows, optimizing field operations and enhancing asset visibility across vast utility service territories.

Industrial IoT Platform Connectivity:

Harness real-time data from your connected devices and sensors, enabling truly predictive maintenance and data-driven decision-making across your factory floor.

Product Lifecycle Management (PLM) Alignment:

Integrate maintenance insights with your PLM system, ensuring that equipment performance data informs future product and process designs.

Conquering Discrete Manufacturing Challenges with MaintWiz AI CMMS

Conquering Chemical Manufacturing Challenges with MaintWiz AI CMMS

Address the unique maintenance and asset management hurdles faced by chemical manufacturers:

Balancing Production Demands with Rigorous Safety Standards:

Implement risk-based maintenance strategies to optimize uptime while ensuring full compliance with PSM requirements.

Ensuring Product Quality in Multi-Product Facilities:

Track and optimize equipment performance across diverse product lines to maintain consistent quality standards.

Optimizing Energy-Intensive Processes:

Implement energy efficiency tracking and analysis to reduce costs and improve sustainability metrics.

Managing Assets in Corrosive and Hazardous Environments:

Utilize advanced corrosion monitoring and predictive analytics to extend equipment life in harsh conditions.

Minimizing Environmental Impact and Emissions:

Monitor and maintain emissions control equipment to ensure continuous compliance with environmental regulations.

Managing Complex Shutdown and Turnaround Operations:

Utilize advanced planning and scheduling tools to minimize downtime during critical maintenance periods.

Rapid Implementation for Immediate ROI in Discrete Manufacturing

Experience a smooth transition to MaintWiz AI CMMS with our tailored implementation process for discrete manufacturing operations.

Comprehensive Asset Mapping and Data Migration:

Quickly catalog your entire manufacturing equipment portfolio and seamlessly transfer historical data, laying a solid foundation for advanced maintenance strategies.

Customized Configuration for Production Workflows:

Tailor MaintWiz to your specific manufacturing processes, ensuring seamless integration with existing production schedules and quality control procedures.

Phased Rollout Across Production Lines:

Implement MaintWiz strategically across your facility, minimizing disruption and allowing for continuous improvement and user adoption.

Intensive Training for Maintenance and Production Teams:

Empower your workforce with comprehensive training programs, ensuring they leverage MaintWiz's full potential for enhanced manufacturing performance.

Continuous Optimization and Support:

Benefit from ongoing system refinement and expert support, ensuring MaintWiz evolves with your changing manufacturing needs and industry trends.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.