Comprehensive AI-driven RCM Solutions for Peak Performance

Enhance operational efficiency with MaintWiz's AI-powered RCM solution. From criticality assessments to predictive analytics, our platform delivers intelligent insights that drive asset reliability, maintenance excellence, reduce downtime, and optimize resource allocation.

Reliability Centered Maintenance

Dive into Detailed Product Information and address your common queries.

Speak to a Specialist

Get personalised advice from our experts

Intelligent RCM Methodology for Enhanced Asset Reliability

Leverage AI-driven RCM methodologies to revolutionize your asset management strategy. Our intelligent system analyzes critical factors, predicts failures, and optimizes maintenance efforts for unparalleled operational efficiency.

AI-Powered Asset Criticality Assessment for Targeted Maintenance

Prioritize assets based on their criticality to your operations to focus maintenance efforts on the most valuable equipment. Boost asset reliability with targeted maintenance strategies.

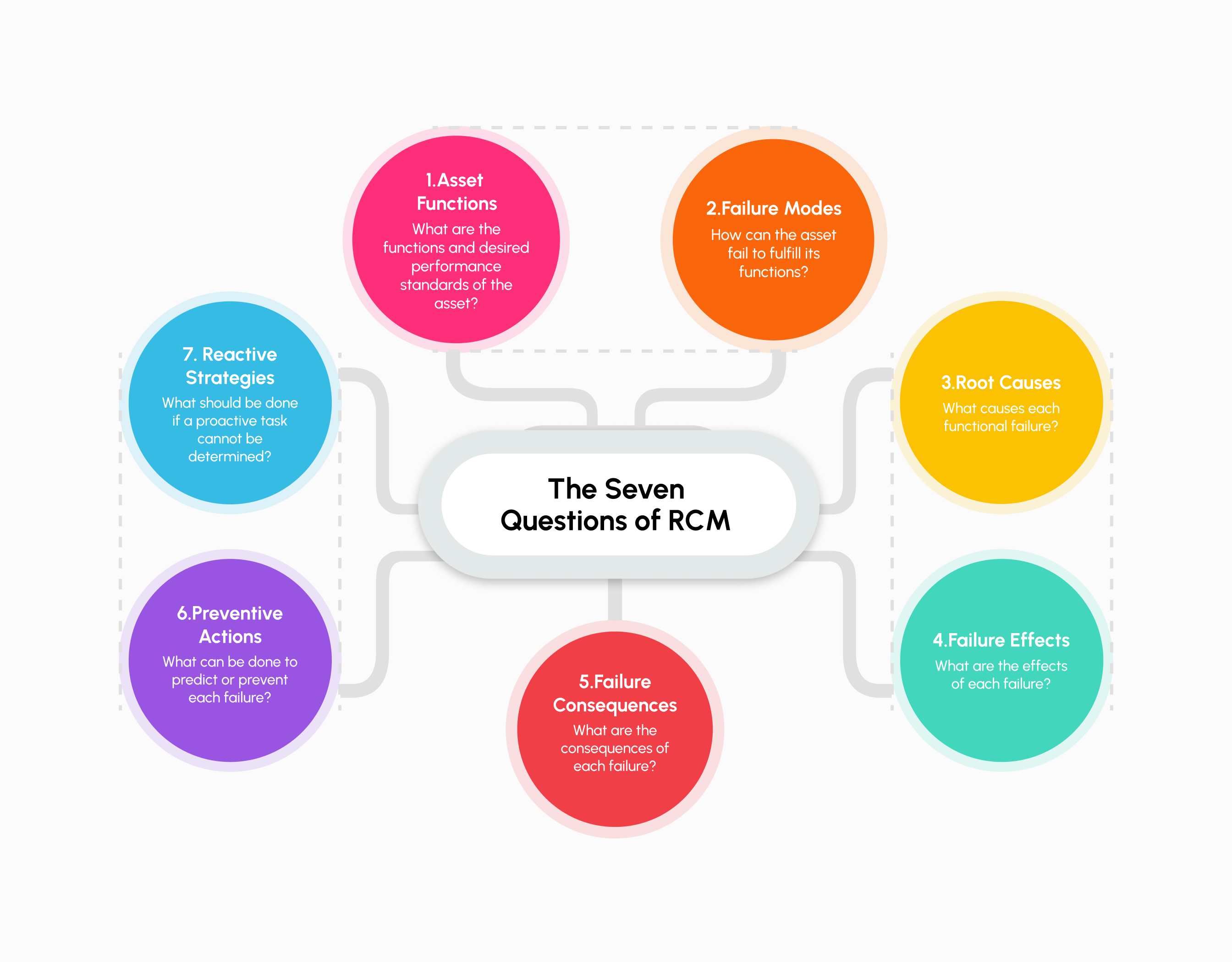

Advanced Failure Consequences Analysis with Machine Learning

With MaintWiz CMMS, evaluate the potential consequences of equipment failures using machine learning algorithms to identify critical failure modes and prioritize risk mitigation measures. Improve asset reliability with AI-driven fail-safe mechanisms.

Intelligent Risk Identification and Assessment for Proactive Maintenance

Identify potential risks associated with equipment failures using AI-powered risk assessment tools. Assess their likelihood and impact to determine appropriate maintenance strategies. Enhance risk assessment with comprehensive AI-driven analysis.

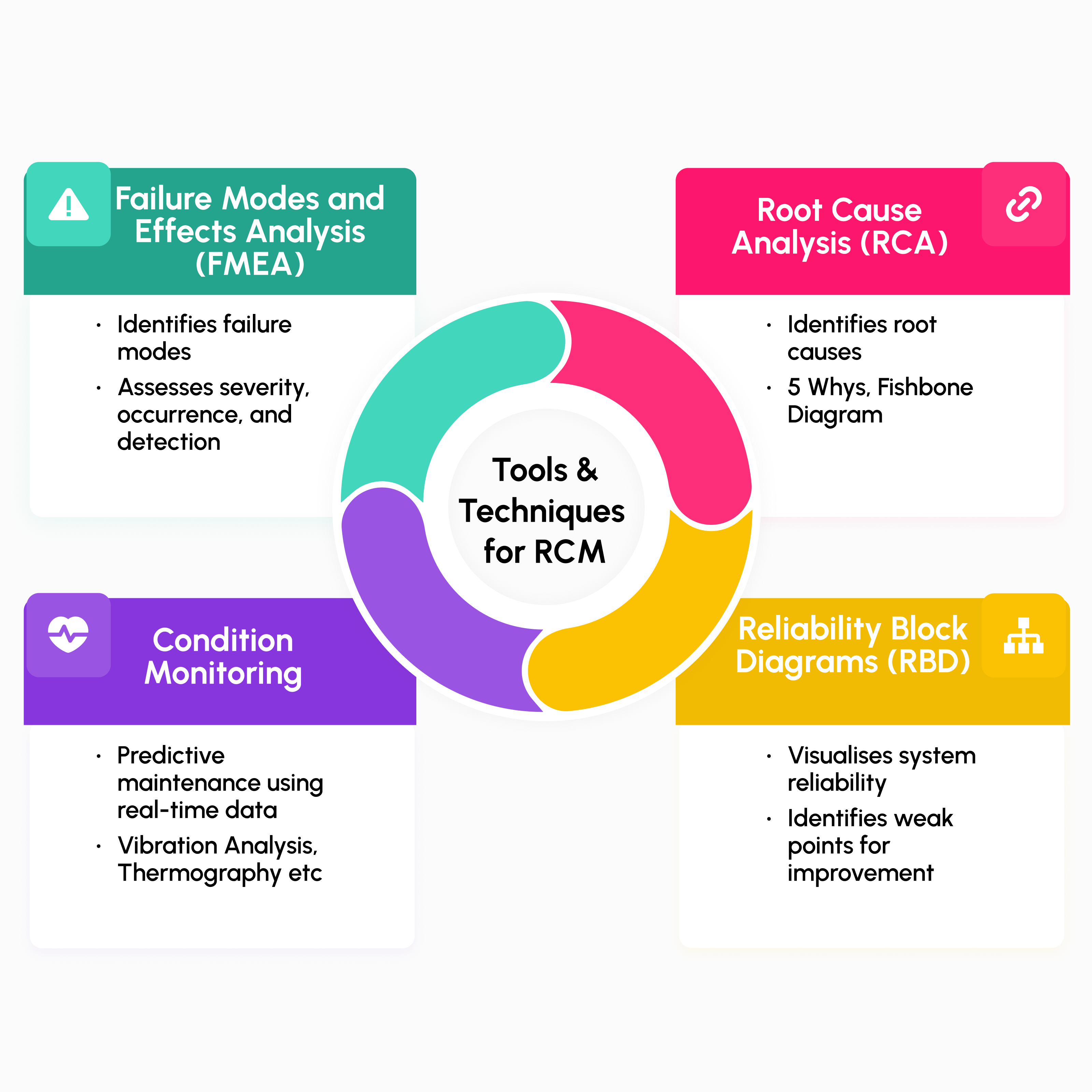

AI-Enhanced FMEA (Failure Mode and Effects Analysis) for In-Depth Insights

Conduct detailed FMEA analyses using AI algorithms to identify potential failure modes, their causes, and their effects on equipment performance and operations. MaintWiz CMMS provides a comprehensive AI-powered FMEA tool for in-depth analysis.

Data-Driven Criticality Analysis for Optimal Maintenance Planning

Analyze the criticality of equipment failures using advanced data analytics to determine the appropriate level of maintenance required. Ensure optimal performance and equipment reliability. Improve RCM strategy with AI-targeted efforts.

AI-Optimized RCM Decision Logic for Effective Maintenance Strategies

Apply established RCM decision logic enhanced by AI to determine the most effective maintenance strategies based on failure modes, consequences, and risk assessments. Optimize decision-making with MaintWiz’s intelligent system.

Top Companies in India & Abroad Trust MaintWiz CMMS

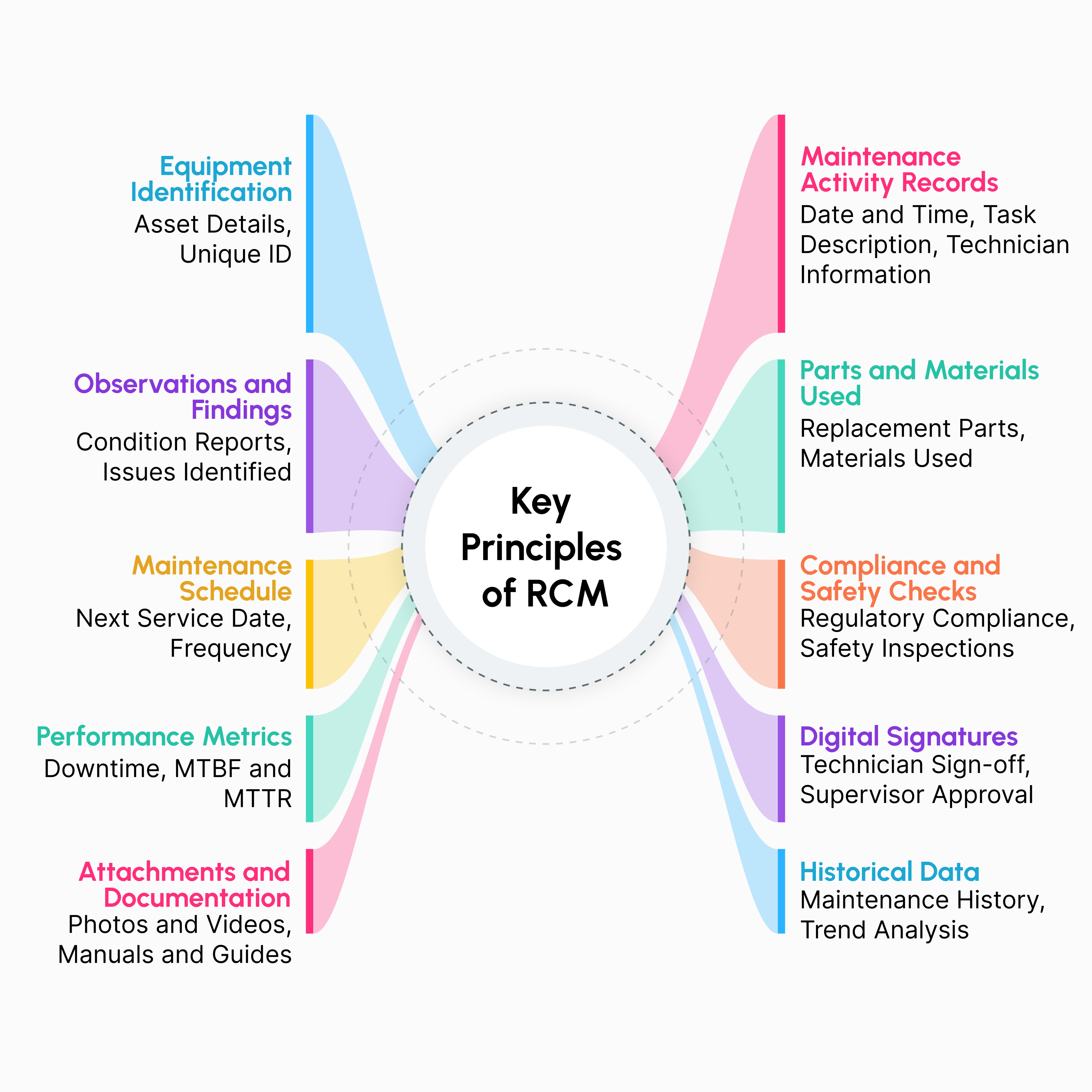

Advanced Data Collection & Analysis for Actionable Insights

Harness the power of AI and machine learning to collect, analyze, and interpret vast amounts of equipment data. Transform raw data into actionable insights for smarter maintenance decisions and improved asset performance.

AI-Driven Equipment and System Data Analysis for Total Asset Reliability

Collect and analyze data on equipment performance, failure history, and maintenance activities using AI algorithms. Identify trends and patterns. MaintWiz RCM provides a total AI-powered solution for asset reliability.

Machine Learning-Enabled Failure History Analysis for Preventive Measures

Analyze historical failure data using machine learning techniques to identify common failure modes, root causes, and potential preventive measures. Implement RCM effectively and efficiently with AI-driven insights.

Real-Time Performance Data Collection with IoT Integration

Collect real-time data on equipment performance using IoT sensors. Assess the effectiveness of maintenance strategies and identify areas for improvement. Drive smart RCM programs with AI-processed real-time insights.

Intelligent RCM Documentation Management System

Create and manage comprehensive RCM documentation using AI-powered document management, including FMEA templates, decision matrices, and maintenance task lists. Ensure thorough documentation for consistent reliability.

AI-Powered Centralized Reporting Tools for Continuous Improvement

Utilize AI-enhanced centralized reporting tools to track RCM performance metrics, monitor progress, and drive continuous improvement. Improve decision-making with AI-processed, accessible equipment data.

Predictive Analytics and AI-Driven Dashboards for Actionable Insights

Access powerful predictive analytics and customizable AI-driven RCM dashboards to provide senior management with actionable insights. Elevate your maintenance strategy with AI-powered, data-driven decision-making.

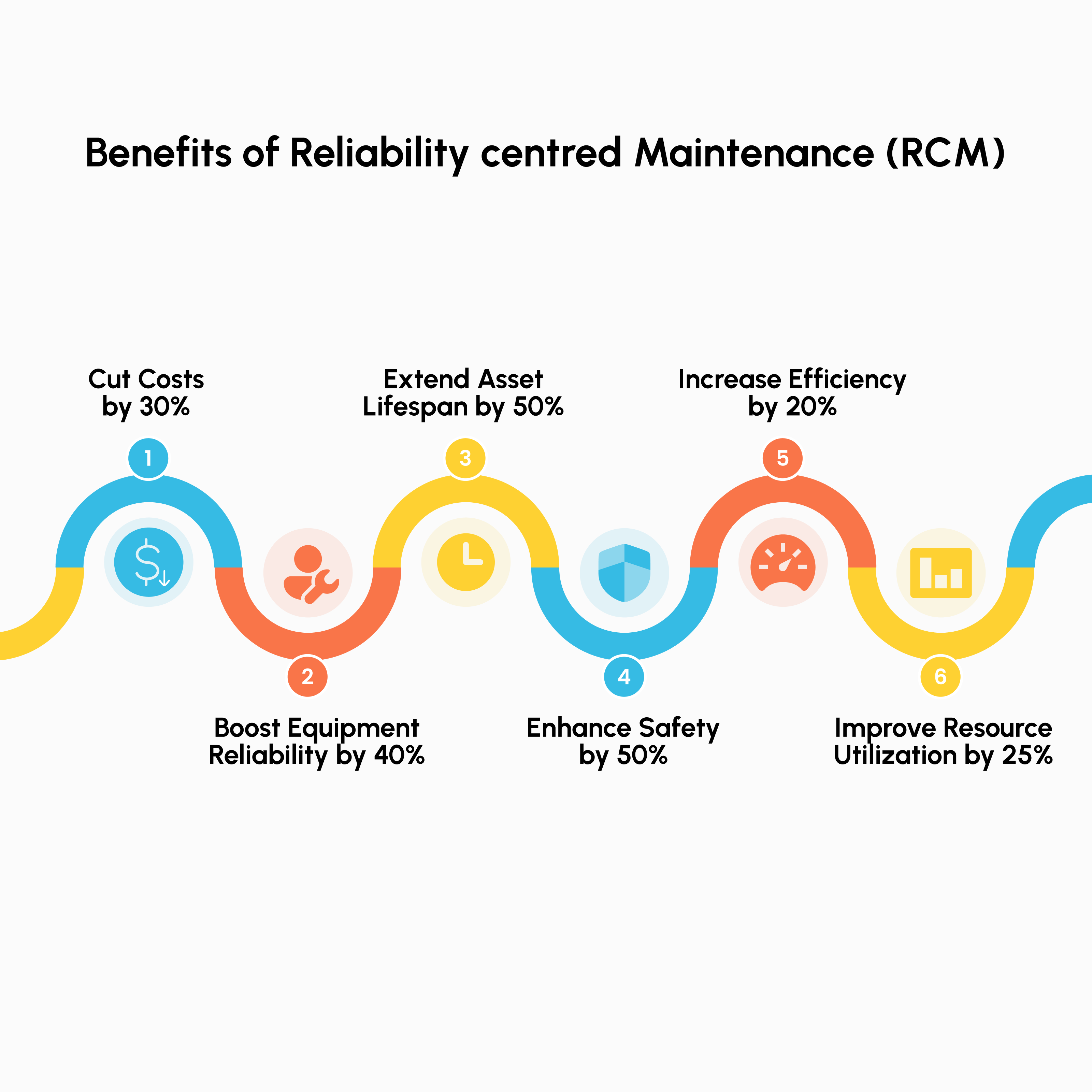

Our Benefits

Intelligent RCM Program Management for Operational Excellence

Optimize your RCM program with AI-driven management tools. From project planning to resource allocation, our intelligent system ensures efficient implementation and continuous improvement of your reliability-centered maintenance strategies.

AI-Optimized RCM Project Planning for Efficient Asset Management

Develop a comprehensive RCM project plan using AI-powered planning tools, including objectives, scope, resources, and timelines. Achieve efficient asset management and RCM implementation with intelligent insights.

Intelligent Resource Allocation for Maximum Workforce Effectiveness

Optimize resource allocation based on AI-driven RCM priorities, ensuring the right resources are available when needed. Maximize workforce effectiveness and optimize maintenance operations with machine learning algorithms.

AI-Powered Reliability Assessment for Continuous Strategy Improvement

Conduct regular reliability assessments using AI analytics to evaluate the effectiveness of RCM strategies and identify areas for improvement. Fine-tune RCM strategies for better equipment performance with data-driven insights.

Intelligent RCM Implementation Roadmap for Strategic Alignment

Create a clear RCM implementation roadmap using AI-driven project management tools, including key milestones, deliverables, and responsibilities that align with organizational goals and objectives. Build a strong RCM culture with intelligent guidance.

AI-Enhanced RCM Training and Development Programs

Invest in AI-enhanced RCM training and development programs to build a knowledgeable team capable of executing RCM strategies. Empower your workforce with essential skills and AI-driven learning tools.

Data-Driven RCM Program Evaluation for Peak Performance

Regularly evaluate the effectiveness of your RCM program using AI-powered analytics to ensure continuous improvement and reliability. Maintain peak performance with ongoing AI-driven evaluations and insights.

Voices of Our Valued Clients

Seamless RCM and Technology Integration for Smart Maintenance

Integrate cutting-edge technologies with our AI-powered RCM solution to create a smart, interconnected maintenance ecosystem. From IoT sensors to predictive analytics, harness the power of technology for unparalleled asset performance.

Advanced IoT and Sensor Integration for Real-Time Asset Monitoring

Integrate IoT sensors and other operational technologies to collect real-time data. Institute AI-driven asset performance monitoring. Improve equipment performance and condition with intelligent insights.

AI-Driven Work Order Generation for Streamlined Maintenance

Automate work order generation based on AI-powered RCM analysis to streamline maintenance processes. MaintWiz connects with IoT sensors and enables AI-driven automated work order creation for proactive maintenance.

Intelligent Spare Parts Management for Optimized Inventory

Optimize spare parts inventory with AI-driven RCM insights, ensuring availability while reducing excess inventory. Achieve peak equipment performance with machine learning-optimized spares management.

Comprehensive Asset Management Integration with AI-Powered RCM

MaintWiz CMMS integrates AI-powered RCM with your asset management to provide a comprehensive view of equipment performance, maintenance history, and risk assessments. Unify asset management and RCM strategies with intelligent data processing.

AI-Enhanced Performance Monitoring for Uninterrupted Operations

Monitor asset performance continuously using AI-processed RCM data. Track analytics via intelligent dashboards, perform AI-driven risk assessments, and conduct machine learning-enhanced FMEA to predict and prevent failures. Ensure uninterrupted operations with smart monitoring.

Advanced Predictive Maintenance with AI and Machine Learning

Leverage AI-powered predictive maintenance analytics to forecast equipment failures with high accuracy. Reduce downtime and optimize maintenance for consistent performance using machine learning algorithms and advanced data analytics.

Achieve RCM. Explore Our Complete Asset Management Solution

Experience unparalleled asset reliability with our state-of-the-art Asset Management and Reliability Centered Maintenance solution. Transform your maintenance approach, enhance operational efficiency, and extend asset lifespan with precision-driven insights.

Predictive Maintenance

Unlock future failures with cutting-edge predictive analytics and keep your assets running smoothly.

Asset Lifecycle Management

Manage your assets from cradle to grave, optimizing performance and reducing total cost of ownership.

Maintenance Scheduling

Ensure timely interventions with smart, automated maintenance scheduling tailored to your needs.

Failure Modes and Effects Analysis (FMEA)

Identify potential failure modes early and mitigate risks effectively with FMEA.

Work Order Management

Streamline work order processes, ensuring tasks are completed efficiently and on time.

Root Cause Analysis (RCA)

Delve deep into issues with RCA and implement lasting solutions to prevent recurrence.

Digital Twin Technology

Create virtual replicas of your assets to simulate and predict performance under different conditions.

Operational Excellence Programs

Drive continuous improvement in your maintenance processes for long-term operational excellence.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.

MaintWiz transformed our maintenance strategy, ensuring peak performance and zero unplanned downtime